February 2025

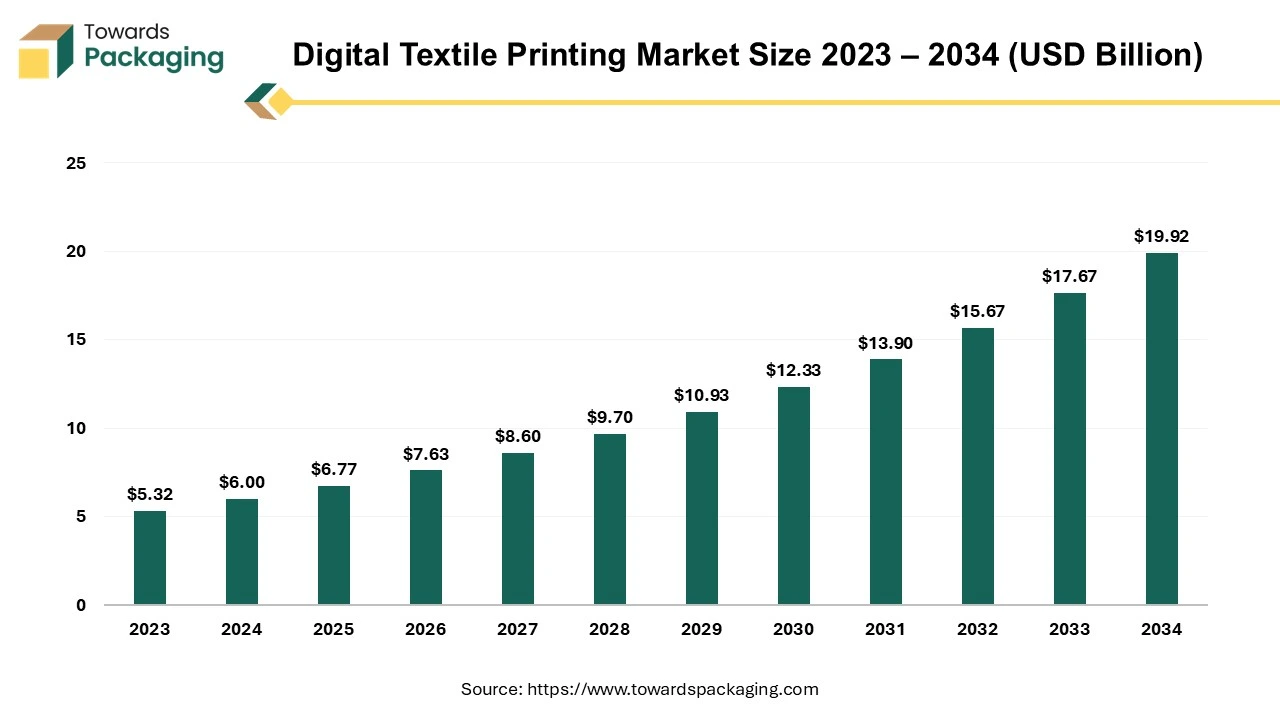

The global digital textile printing market, valued at USD 6.77 billion in 2025, is expected to reach approximately USD 19.92 billion by 2034, growing at a CAGR of 12.75% from 2024 to 2034. Key market players are increasingly adopting inorganic growth strategies, such as mergers and acquisitions, to drive technological advancements and expand their market presence.

Digital textile printing is a process of printing designs onto fabrics utilizing digital technology. Unlike traditional methods such as screen printing, digital printing enables for more precise and versatile printing directly onto the textile. Digital printing allows intricate and detailed designs with unlimited color combinations. It allows for quick changes to designs without the need for extensive setup. Small production runs and custom designs are more feasible with digital printing, making it ideal for personalized items or limited-edition products.

The process is faster and more cost-effective for short runs since it eliminates the need for screens or plates. Digital textile printing typically uses less water and generates less waste compared to traditional printing methods. The digital textile printing technology is utilized in various industries, including home décor, fashion, and promotional products.

Advancements in inkjet technology, automation and color management, have improved the quality, speed, and efficiency of digital textile printing, enabling more intricate and vibrant designs on various fabrics. Innovations like UV gel technology are expanding application possibilities, allowing businesses to tap into new market segments.

Digital textile printing uses gentler chemicals and solvents compared to traditional methods, aligning with the rising emphasis on eco-friendly practices and cost-effective production. There is growing consumer demand for sustainable and customizable textile solutions, prompting manufacturers to adopt digital textile printing due to its lower environmental footprint.

The capability to produce high-quality, intricate designs quickly and cost-effectively makes digital textile printing an attractive choice for both small and large-scale operations, catering to the increasing demand for unique and personalized products. The fashion industry is leveraging digital printing to develop unique, high-fashion garments quickly and efficiently, catering to the dynamic demands of fast fashion.

The artificial intelligence integration has ability to significantly enhance the digital textile printing industry by design optimization and personalization. The AI integration generates unique and complex textile patterns, reducing the time and effort required for manual design. AI-driven tools has ability to analyze customer preferences and trends to provide personalized design recommendations, allowing for more tailored products. AI tools has ability to identify defects or inconsistencies in fabric prints in real-time, ensuring higher quality standards and reducing waste. AI algorithms can optimize color matching and consistency across different batches, improving product uniformity.

AI software has ability to automate various stages of the printing process, from design preparation to fabric handling, enhancing efficiency and reducing labor costs. AI has ability to monitor equipment performance and predict maintenance needs, minimizing downtime and prolonging the lifespan of machinery. AI has ability to enable virtual try-ons for customers, allowing them to visualize how designs will look on different fabrics and garments. AI chatbots and virtual assistants can offer 24/7 customer support, improving service quality and customer satisfaction. Integrating AI into the digital textile printing industry can lead to greater efficiency, innovation, and competitiveness, while also fostering sustainability and customer-centricity.

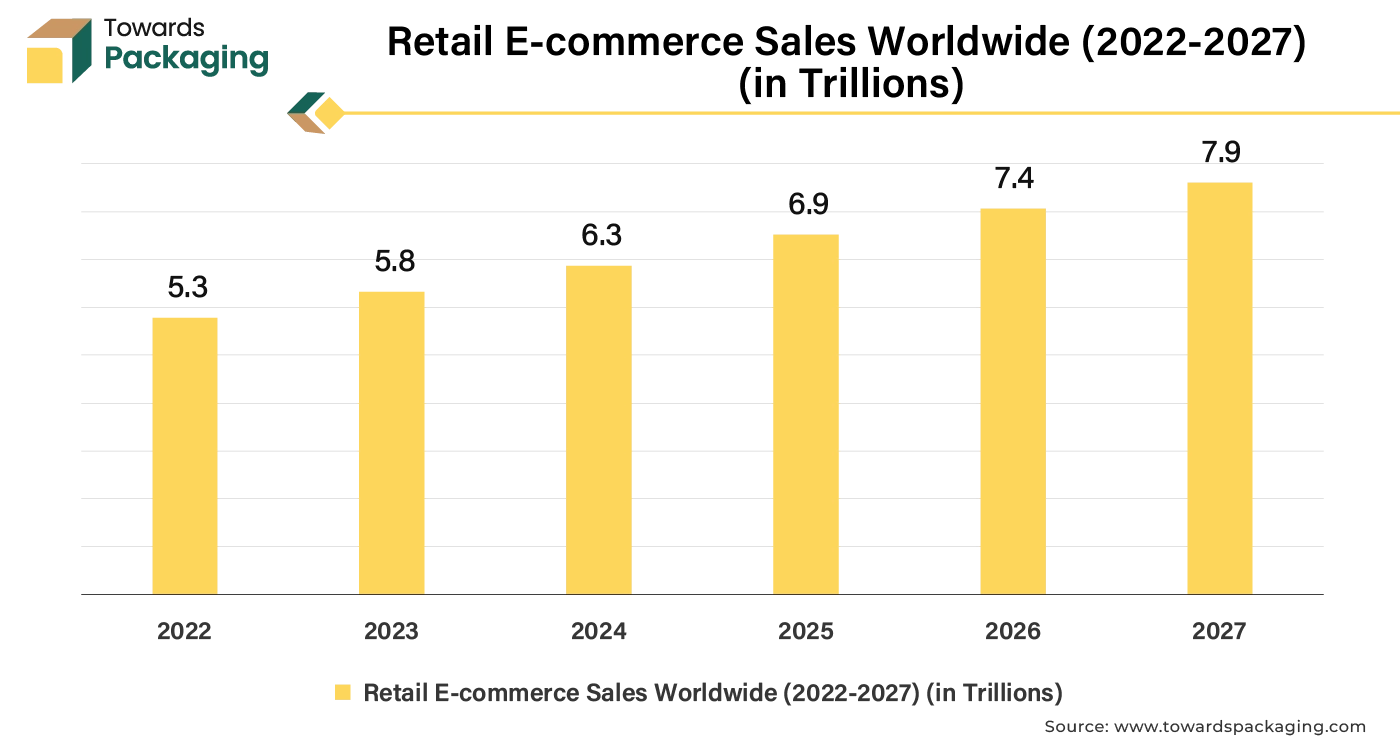

The rise of e-commerce platforms has increased demand for digitally printed textiles, as businesses seek quick, customizable solutions for online orders. Direct-to-consumer models are growing, allowing consumers to order custom designs directly from manufacturers, supported by digital textile printing. E-commerce platforms enable consumers to order personalized and custom-designed products, which has led to a surge in demand for customized textiles. Digital textile printing allows for high levels of customization, including personalized designs, colors, and patterns, making it ideal for this market. E-commerce thrives on fast delivery. Digital textile printing supports just-in-time production, allowing businesses to produce and ship products quickly, meeting the high expectations of e-commerce consumers.

With digital textile printing, companies can produce items on demand, reducing the need for large inventories. This aligns with the e-commerce model, where businesses often operate with lean inventory to reduce costs and risks. E-commerce consumers are increasingly conscious of sustainability. Digital textile printing is generally more environmentally friendly than traditional printing methods, using less water and producing less waste, which can be a selling point for eco-conscious buyers. The growth of e-commerce drives the demand for flexible, customizable, and sustainable production methods, making digital textile printing an integral part of this ecosystem.

The key players operating in the market are facing issue due to need of technical expertise and limited fabric availability, which has restricted the growth of the digital textile printing market in the near future. Digital printing may not be compatible with all types of fabrics, especially natural fibers like cotton, which often require pre-treatment. This limits its application scope. The durability and color fastness of digital prints can be lower than traditional methods, particularly for high-wear applications like sportswear. Compared to traditional screen printing, digital textile printing can be slower, making it less suitable for high-volume production.

The slower speed can be a limiting factor for large-scale manufacturers looking to meet high demand efficiently. Operating and maintaining digital textile printers require skilled technicians and designers familiar with the technology, which can be a challenge in regions with limited expertise. Companies may face additional costs and time investments in training staff, further complicating adoption.

The specialized inks used in digital textile printing can be expensive, impacting profitability, especially for small-scale runs. Achieving certain colors or effects may be difficult with digital inks, which can limit design options and affect customer satisfaction.

Innovations in digital printing technologies, such as faster print speeds, better print quality, and more durable inks, are enhancing the industry’s capabilities. The adoption of artificial intelligence for design automation, quality control, and predictive maintenance, along with internet of things for real-time monitoring, is boosting efficiency and productivity. Hence, due to increasing launch of the advanced technology digital printing machines, it has created lucrative opportunity for the growth of the digital textile printing market in the near future.

The VC40000 has two different ink set optionsmono pigment, which is best suited for book printing, and dye, which is intended for transactional printing. At maximum speed, the press is said to be able to print at 600 x 600 dpi at 180 m/min. With a print quality of 600 x 300 dpi, the mono dye version can operate at 225 meters per minute.

The direct to fabric (Roll to Roll Printing) segment held a dominant presence in the digital textile printing market in 2024. Direct to fabric (Roll to Roll Printing) printing allows for intricate designs and a wide range of colors, making it ideal for producing custom and personalized textiles. This flexibility caters to the growing demand for unique and tailored products in fashion, home décor, and other industries. Direct to fabric (Roll to Roll Printing) technology facilitates on-demand production, enabling faster turnaround times compared to traditional methods. This is particularly beneficial for meeting the quick delivery expectations of modern consumers and the fast-paced nature of fashion trends.

Traditional textile printing methods are often cost-prohibitive for small batches due to setup costs. Direct to fabric (Roll to Roll Printing) printing eliminates the need for screens or plates, making it economically viable for short runs and small businesses. Direct to fabric (Roll to Roll Printing) printing is compatible with various types of fabrics, including cotton, polyester, silk, and blends. This versatility allows manufacturers to produce diverse products, from apparel to home textiles. The digital nature of Direct to fabric (Roll to Roll Printing) printing simplifies the design-to-production process. Designers can easily transfer digital designs to fabric without the need for complex setup procedures, reducing time and labor costs.

The single pass segment registered its dominance over the global digital textile printing market in 2024. Single-pass printing technology enables extremely fast printing speeds as the fabric passes under stationary print heads in a single motion. This makes it ideal for large-scale production, significantly increasing output compared to multi-pass systems. Single-pass digital textile printing machines are widely used in the market due to several advantages that make them suitable for high-volume and high-speed production. While the initial investment in single-pass printers can be high, their cost efficiency improves with large production volumes. The speed and reduced labor requirements lead to lower per-unit costs over time.

Single-pass printers can handle different types of fabrics, including silk, polyester, cotton, and blends. This versatility allows manufacturers to produce a wide range of textile products for different markets, such as fashion, home textiles, and technical textiles. Single-pass digital printing often utilization of less ink and water compared to traditional printing methods, minimizing environmental impact. The technology also minimizes fabric waste and supports sustainable production practices.

Single-pass printers often support advanced ink technologies, such as reactive, pigment, sublimation, and acid inks, enabling vibrant colors, strong durability, and compatibility with different fabric types. Popular brands and models of single-pass digital textile printing machines in the market include those from companies like Durst, SPGPrints, and EFI Reggiani known for their innovation and reliability in textile printing technology.

The cotton segment accounted for a considerable share of the digital textile printing market in 2024. Cotton is a natural fiber known for its softness, breathability, and comfort. These qualities make it a preferred choice for various applications, including fashion, home textiles, and accessories. Cotton fibers have a high absorption rate, which allows them to take in dyes and inks effectively. This results in vibrant, long-lasting colors and sharp print quality, essential for high-resolution digital printing.

Cotton fabric is durable and strong, withstanding multiple washes and wear. This durability ensures that printed designs remain intact and vibrant over time, making it a reliable choice for consumers. As a renewable and biodegradable resource, cotton is considered a more sustainable option compared to synthetic fabrics. The growing demand for eco-friendly products has further boosted its popularity in the textile printing industry. Cotton is one of the most widely grown and used natural fibers globally, making it readily available for textile production. Its accessibility assists in maintaining a steady supply chain for manufacturers.

The sublimation segment dominated the digital textile printing market globally. Sublimation inks produce bright, vibrant colors that are deeply embedded into the fabric fibers, resulting in prints that are durable and resistant to fading, even after multiple washes. Since the dye becomes part of the fabric rather than sitting on top of it, sublimation prints are highly durable. They resist cracking, peeling, and fading, ensuring long-lasting quality. Sublimation printing is relatively eco-friendly compared to traditional methods. It uses less water and produces minimal waste, as the process transfers the dye directly into the fabric without the need for extensive post-processing.

Sublimation is suitable for a wide range of applications, including apparel, sportswear, home décor, and promotional items. It works particularly well on polyester fabrics, which are commonly used in these products. The sublimation process is quick, allowing for fast production times. This is crucial for meeting the demands of fast fashion and the rapid delivery expectations of the e-commerce market. Unlike screen printing, which adds layers of ink on top of the fabric, sublimation integrates the ink into the fabric, resulting in a soft, breathable finish that maintains the fabric's original feel.

Sublimation inks provide an extensive color gamut, allowing the reproduction of a broad range of colors with high precision. This is especially important for designs requiring exact color matching.

The clothing/apparel segment registered its dominance over the global digital textile printing market in 2024. Digital printing enables faster production cycles, as designs are directly printed onto fabric without the need for traditional screens or setup processes. This results in quicker turnaround times for apparel manufacturers, minimizing lead times and enables for faster adaptation to market trends, which is increasingly important in the fast-moving fashion industry.

The fashion industry is under pressure to become more sustainable, and digital textile printing can contribute to this by minimizing water usage, waste, and energy consumption compared to traditional printing methods. As sustainable fashion continues to rise in popularity, the adoption of eco-friendly technologies like digital printing will increase, further stimulating market growth. Digital textile printing allows for the reproduction of complex, detailed, and multi-colored designs without the limitations of traditional methods. This flexibility makes it an attractive option for apparel brands looking to offer a diverse range of designs that appeal to a broad customer base.

Asia Pacific region held the largest share of the market in 2024 and is observed to sustain the dominance during the forecast period. The fashion industry in the Asia Pacific region is characterized by quick changes in trends. Digital textile printing enables manufacturers to produce designs quickly and adapt to new trends without the need for large inventories. Asia Pacific is a hub for technological innovation and manufacturing. Advancements in digital textile printing technology, such as high-speed printers and eco-friendly inks, are readily adopted, driving growth in the industry. Many countries in the Asia Pacific have supportive infrastructure and government policies that encourage the growth of the textile and fashion industries, indirectly benefiting the digital textile printing market.

North America is observed to grow at the fastest pace during the forecast period. North America is home to many leading technology companies and innovators, which contributes to the development and adoption of advanced digital printing technologies. North America region has a well-established textile and fashion industry that continuously seeks innovative printing solutions to meet evolving consumer preferences. Digital textile printing is more environmentally friendly compared to traditional methods, and North America's emphasis on sustainability encourages the adoption of such technologies. Digital textile printing is extensively utilized for creating banners, flags, and other promotional materials. The demand for high-quality, visually appealing advertising materials drives growth in this region.

By Printing Process

By Material Operation

By Material

By Ink Type

By Application

By Region

February 2025

January 2025

January 2025

January 2025