April 2025

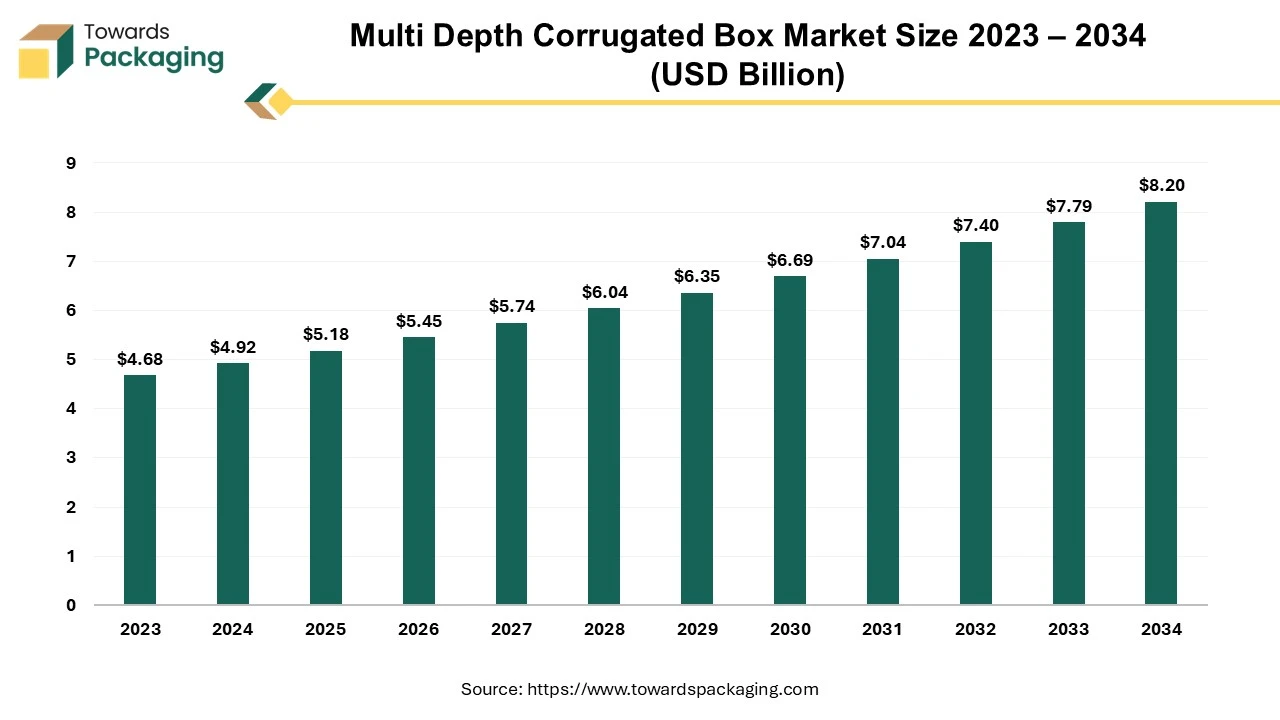

The multi depth corrugated box market is forecast to grow from USD 5.18 billion in 2025 to USD 8.20 billion by 2034, driven by a CAGR of 5.23% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

A multi-depth corrugated box is a type of packaging designed with multiple score lines that allow the box to be adjusted to different heights. This feature makes the box versatile for packaging items of various sizes. By cutting along the score lines, consumers can customize the box’s depth to fit the product securely, minimizing wasted space and reducing shipping costs. This adaptability is particularly useful for e-commerce and shipping industries where flexibility in packaging can be crucial.

Multi depth corrugated box can be adjusted to various depths, making it suitable for packaging items of different sizes without needing multiple box types. Multi depth corrugated box reduces the need for multiple box sizes, which can lower inventory and storage costs. The multi depth corrugated box assists in minimizing empty space within the box, leading to better protection for items and potentially lowering shipping costs. It simplifies stock management by reducing the variety of box sizes needed. Multi depth corrugated box offers flexibility in packaging, allowing for quick adjustments to fit specific product dimensions. By using multi depth corrugated box less material is wasted due to better fitting of products within the box.

A multi-depth corrugated box is a type of shipping container that is designed to be adjustable to different depths or heights. This adaptability is achieved through a specific construction method where the box has multiple pre-scored lines or folds at various depths. The multi depth corrugated box is made from corrugated cardboard, which is a type of fluted paper sandwiched between two liners. The multiple depth option is created by scoring the box at various heights. This allows the box to be folded or cut at different points to adjust its height. By folding along the pre-scored lines, the multi depth corrugated box can be adjusted to fit various sizes of products. This feature is particularly useful for businesses that need a flexible packaging solution for different product dimensions. Multi-depth boxes can reduce the need for stocking multiple box sizes, which can lower inventory costs and minimize waste. Companies can use a single type of box for various products, making it a cost-effective solution.

Multi depth corrugated boxes maintain structural integrity and offer protection during shipping despite their adjustable nature. The corrugated material provides cushioning and strength. Multi-depth corrugated boxes are commonly used in industries like retail, e-commerce, and logistics where products of various sizes need to be shipped efficiently. They are particularly beneficial for companies with fluctuating product dimensions. In summary, multi-depth corrugated boxes offer flexibility and cost savings by allowing one box to serve multiple purposes, accommodating various product sizes through adjustable heights.

AI can improve the design and manufacturing of multi-depth corrugated boxes in a number of ways. AI can optimize box design and dimensions for particular shipping requirements, saving material waste and maximizing available space. During production, AI-powered vision systems may identify flaws in corrugated boxes, guaranteeing uniform quality and cutting waste.

Manufacturers can modify production plans and inventory by using AI to estimate demand for various box sizes and designs.AI-driven technologies can help with the creation of unique designs depending on the specifications for the product's dimensions and packaging. By anticipating possible hiccups and recommending the best sourcing and distribution plans, artificial intelligence (AI) helps optimize the supply chain. AI is capable of analyzing market trends and consumer input to inform the creation of more enticing and functional box designs. Manufacturers may improve multi-depth corrugated box quality, cut costs, and increase productivity by incorporating these AI capabilities.

AI-driven analytics can provide insights into consumer preferences and trends related to multi depth corrugated box packaging. Al technologies facilitate more effective sorting, improving quality control procedures, maximize composting operations, and direct the creation of more environmentally friendly packaging solutions, all of which improve the recycling and composability of packaging materials.

AI algorithms are able to assess the environmental impact of different packaging materials, helping companies choose packaging that is less harmful to the environment. Al can assist in optimizing packaging designs to use the least amount of material while preserving product integrity, which will reduce waste and the environmental impact of the packaging.

Al is used by Amazon to minimize product damage and improve packaging. Amazon analyzes real-world consumer complaint data using a machine learning model to find trends and enhance the packaging for a range of products bought through its website. An artificial Intelligent algorithms enhance order fulfillment precision and minimize waste in the packing processes of commerce fulfillment centers. A further factor influencing the use of Al in packaging is the evolution of consumer tastes and needs. Algorithms evaluate customer data to generate customized package experiences and boost brand allegiance. Businesses are using Al to create better packaging designs, utilize less material, and have a more minimal environmental impact because to concerns about sustainability.

Amazon’s Trial on AI Innovations in Packaging

The Al chooses the best kind of packaging for anything from common home goods to the most unusual gifts, trying to use as little cardboard, air cushions, and tape as possible in order to support the company's sustainability goals. Utilizing computer vision, natural language processing, and deep machine learning, the Al model runs on the Amazon Web Services (AWS) cloud. It is capable of making well-informed decisions, such as determining whether a fragile item needs a stronger box or whether a durable item, like a blanket, doesn't need extra protective packing. The enormous and dynamic product library that Amazon offers drives this ongoing learning process, thus the accuracy and adaptability of the model are essential.

Georgia-Pacific LLC’s Trial on Capital Improvement

The rise of online shopping has increased the need for versatile packaging solutions that can accommodate a wide range of product sizes and shapes. One of the primary drivers of the multi depth corrugated box market is the growing consumer demand for environmentally friendly packaging choices. Environmental concerns are pushing businesses to implement eco-friendly practices and goods. Corrugated boxes made of recyclable materials, which are driving market expansion, assist this trend. One of the main factors driving the multi depth corrugated box industry is the growing e-commerce landscape. The growth of online shopping necessitates flexible packaging solutions that can manage a large range of product lines and ensure faultless delivery experiences.

Corrugated boxes are the perfect answer to this need and a great way to grow the market because they can be built to any depth. Multi-depth boxes reduce the need for multiple box sizes, leading to savings in inventory costs, transportation, and storage. As businesses strive to reduce waste and improve sustainability, multi-depth corrugated boxes help by minimizing material use and reducing packaging waste. The online shopping stores as well as various clothing brands constantly put up sale or discount offer which attracts costumers and indirectly has risen the demand of the multi depth corrugated box for shipping purpose which is estimated to drive the growth of the multi depth corrugated box market over the forecast period.

For instance,

The key players operating in the market are facing issues related to high cost of machine deployment and raw material assembly which is major factor creating complexity in manufacturing which is hampering the growth of the multi depth corrugated box market. The production of multi-depth boxes can be more expensive compared to standard single-depth boxes, impacting overall cost-efficiency for some businesses. Multi-depth boxes require more sophisticated manufacturing processes and machinery, which may not be feasible for all packaging companies, especially smaller ones. While multi-depth boxes offer flexibility, they may not provide the same level of customization as fully tailored packaging solutions, potentially limiting their appeal for specific branding needs.

In regions where the market is saturated with packaging solutions, new entrants may find it challenging to gain traction or differentiate themselves with multi-depth boxes. Disruptions or inefficiencies in the supply chain can affect the availability and timely delivery of multi-depth boxes, impacting businesses that rely on consistent packaging solutions. The availability of other innovative packaging solutions, such as adjustable inserts or more advanced materials, might offer more specific benefits compared to multi-depth boxes, potentially diverting demand.

Businesses aiming to improve their product presentation and customer interaction are drawn to the possibility of customizing multi-depth boxes for branding and marketing objectives. Multi-depth corrugated boxes are becoming more and more popular as the retail and consumer goods industries grow and the requirement for packaging that offers protection and improves shelf appeal grows along with them.

Automation and intelligent packaging solutions are two examples of innovations in corrugated box production that open up possibilities for improved functionality and efficiency. The industrial and consumer sectors are growing in emerging economies in Asia-Pacific, Latin America, and Africa, which is driving up demand for adaptable and affordable packaging solutions. The key players operating in the market are focused on adopting organic growth strategies like marketing of technology used for manufacturing corrugated boxes which is estimated to create lucrative growth opportunities for the multi depth corrugated box market

For instance,

The 180 t0 300 lbs segment held the dominating share of the multi depth corrugated box market in 2024. A multi-depth corrugated box with 180 to 300 lbs are designed to handle substantial weights, reducing the risk of collapse or damage during handling and transit. Multi-depth boxes with 180 – 300 lbs can be easily adjusted to fit different product sizes by cutting along pre-scored lines, which helps in efficiently using space and protecting products.

The high strength of these boxes offers excellent protection against impact, compression, and environmental factors, helping to prevent damage to contents. These boxes can be tailored with additional features such as reinforced edges or cushioning materials for extra protection, enhancing their effectiveness. The multi depth corrugated box with 180 – 300 lbs are extensively utilized as industrial packaging solution. The key players operating in the textile industry are launching new clothing piece and new clothing brand which is seen to increase the demand for the 180-300 lbs multi depth corrugated box for shipping and transportation purpose, which is estimated to drive the growth of the segment over the forecast period.

For instance,

Above 300 lbs segment is estimated to grow at fastest rate over the forecast period. The 300 lbs multi depth corrugated boxes can handle heavier loads and resist more stress, reducing the risk of damage during shipping and handling. Multi-depth boxes above 300 lbs can be adjusted to different heights, accommodating various product sizes while optimizing packing material use. It even reduces the need for multiple box sizes, potentially lowering inventory and shipping costs. Above 300 lbs multi depth boxes are widely used for carrying the heavy parts of the car in the automobile sector.

The triple wall multi depth corrugated box segment is estimated to show significant growth in 2024. The triple wall multi depth corrugated box can support significant weight, making them ideal for shipping heavy or bulky items. Their multi-layer construction provides extra cushioning and resistance to impacts, reducing the risk of damage during transportation. They offer better resistance to compression, moisture, and rough handling, which is crucial for maintaining the integrity of the contents. Although more expensive than single or double-wall boxes, they can be more cost-effective for heavy shipments by reducing damage rates and associated costs.

Triple wall multi depth corrugated box is suitable for various industries, including automotive, electronics, and industrial goods, where strong and reliable packaging is essential. Overall, their strength and protection make them a preferred choice for demanding shipping and storage applications. Triple wall multi depth corrugated boxes are best suited for packaging medical and diagnostic devices and machines. Increasing launch of new medical devices as well as machines has risen the demand of the triple wall multi depth corrugated box which is estimated to drive the growth of the segment over the forecast period.

For instance,

Hence, increasing launch of the new medical devices and diagnostic equipment has risen the demand for the triple wall multi depth corrugated box for safe and secure storage as well as transportation.

Double wall multi depth corrugated box is estimated grow at fastest rate over the forecast period. Double wall multi-depth boxes can be adjusted to various heights by cutting along pre-scored lines, accommodating different product sizes and reducing the need for multiple box types. The double wall construction provides superior strength and cushioning, reducing the risk of damage during shipping and handling.

By minimizing the need for multiple box sizes, businesses can reduce inventory and storage costs. These boxes are often made from recyclable materials, contributing to more sustainable packaging practices. The ability to customize box depth on-site can simplify packaging processes and improve operational efficiency. The uniformity and strength of double wall boxes contribute to a more polished and professional presentation of products.

The heavy duty double wall segment held the dominating share of the multi depth corrugated box market in 2024. The double layers of the multi depth corrugated box offer superior protection against impacts, crushing, and punctures during transit and handling. The heavy duty double wall multi depth corrugated box consists of additional layer that provides better insulation against temperature fluctuations, helping to protect temperature-sensitive products. It reduces the likelihood of damage to the contents due to presence of its heavy duty double wall protection, leading to fewer returns and customer complaints. The rise in online shopping has driven demand for durable and protective packaging solutions like heavy duty multi depth double wall corrugated boxes, which provide better protection during transit.

Growth in consumer goods and retail sectors increases the need for robust packaging to ensure product safety and quality. Heavy duty double wall multi depth corrugated boxes are recyclable and biodegradable, aligning with the growing emphasis on sustainable and eco-friendly packaging solutions. These boxes offer cost-effective packaging solutions compared to alternatives, especially for shipping and handling.

Advances in manufacturing technology have enhanced the quality and customization of heavy duty double wall corrugated boxes, making them more attractive to various industries. Increased international trade requires reliable packaging solutions to protect goods across longer distances and diverse handling conditions. The key players operating in the market are focused on launching new technology in the market to develop the heavy duty double wall multi depth corrugated box packaging technology in order to meet the rising demand by the costumers, which is estimated to drive the growth of the segment over the forecast period.

For instance,

The food and beverages industry segment held the dominating share of the multi depth corrugated box market in 2024. The multi depth corrugated box offers excellent protection against physical damage, such as impacts, vibrations, and stacking pressure, which is crucial for preserving the quality and safety of food and beverages during transportation and storage. The multi-depth design allows for flexibility in packaging sizes.

Boxes can be easily adjusted to accommodate different product dimensions without needing multiple box sizes, reducing packaging waste and inventory costs. Multi depth corrugated boxes are strong and resilient, providing robust support and protection to ensure that products arrive intact and in good condition. By using a single type of multi depth corrugated box that can be adjusted to various sizes, companies save on the cost of maintaining multiple box types and reduce overall packaging expenses. Multi depth corrugated boxes are typically made from recyclable materials, aligning with eco-friendly practices and helping companies meet environmental regulations and consumer expectations.

These boxes are designed to be easy to handle, stack, and transport, facilitating efficient operations in warehouses and during distribution. Overall, multi-depth corrugated boxes offer a practical and efficient solution for the diverse packaging needs of the food and beverage industry. The key players operating in the market are focused on launching multi depth corrugated boxes for food & beverages industry which is estimated to drive the growth of the segment over the forecast period.

For instance,

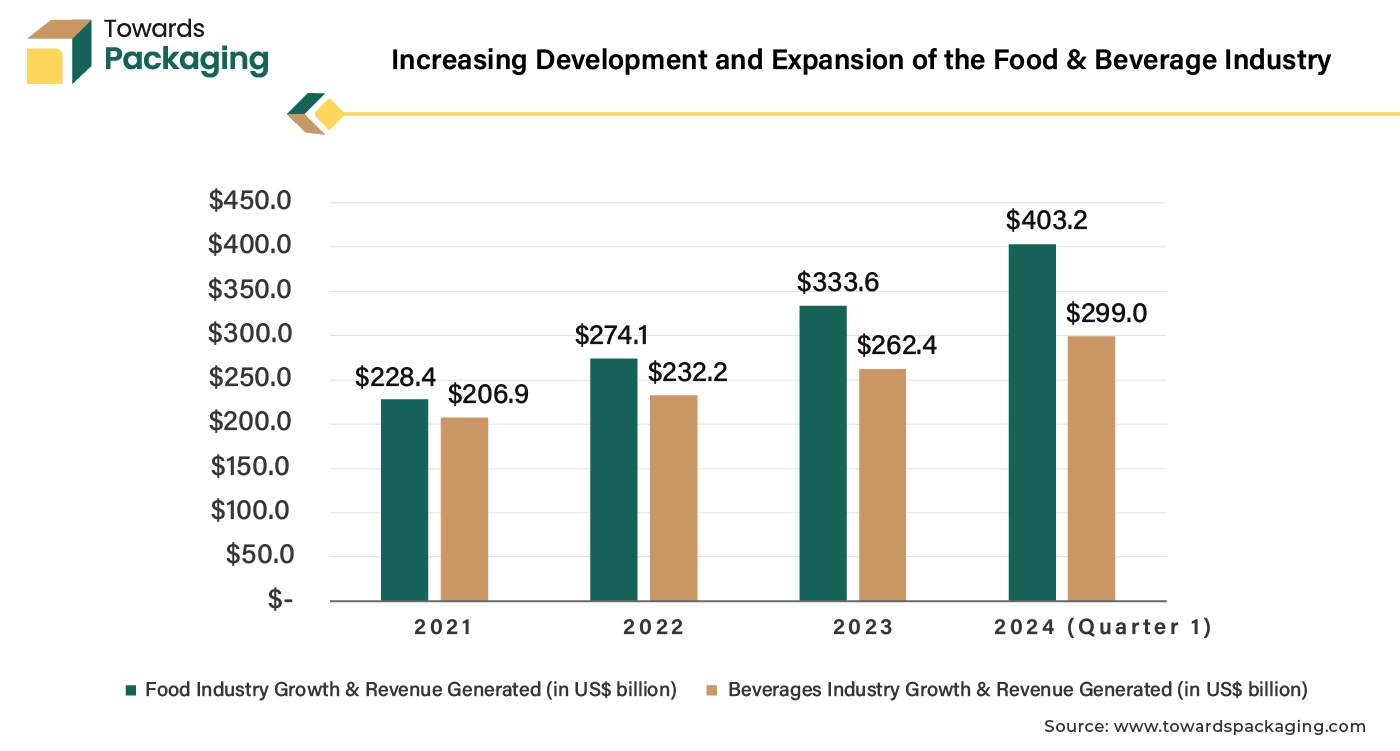

Moreover, increasing development and expansion of the food & beverage industry has risen the demand for the multi depth corrugated box, which is estimated to drive the growth of the segment over the forecast period.

The consumer electronics segment is estimated to grow at fastest rate over the forecast period. Consumer electronics products vary significantly in size and shape. Multi-depth boxes can be adjusted to fit different products securely, reducing the need for multiple box sizes. Multi-depth boxes offer better protection by allowing for customized fit, which minimizes movement and potential damage during shipping and handling. Using a single type of box with adjustable depths can reduce inventory costs and simplify logistics compared to stocking a range of box sizes. They provide flexibility in packaging operations, making it easier to handle changes in product dimensions without the need for new box designs. Overall, multi-depth corrugated boxes help streamline consumer electronics packaging processes, enhance product protection, and reduce costs.

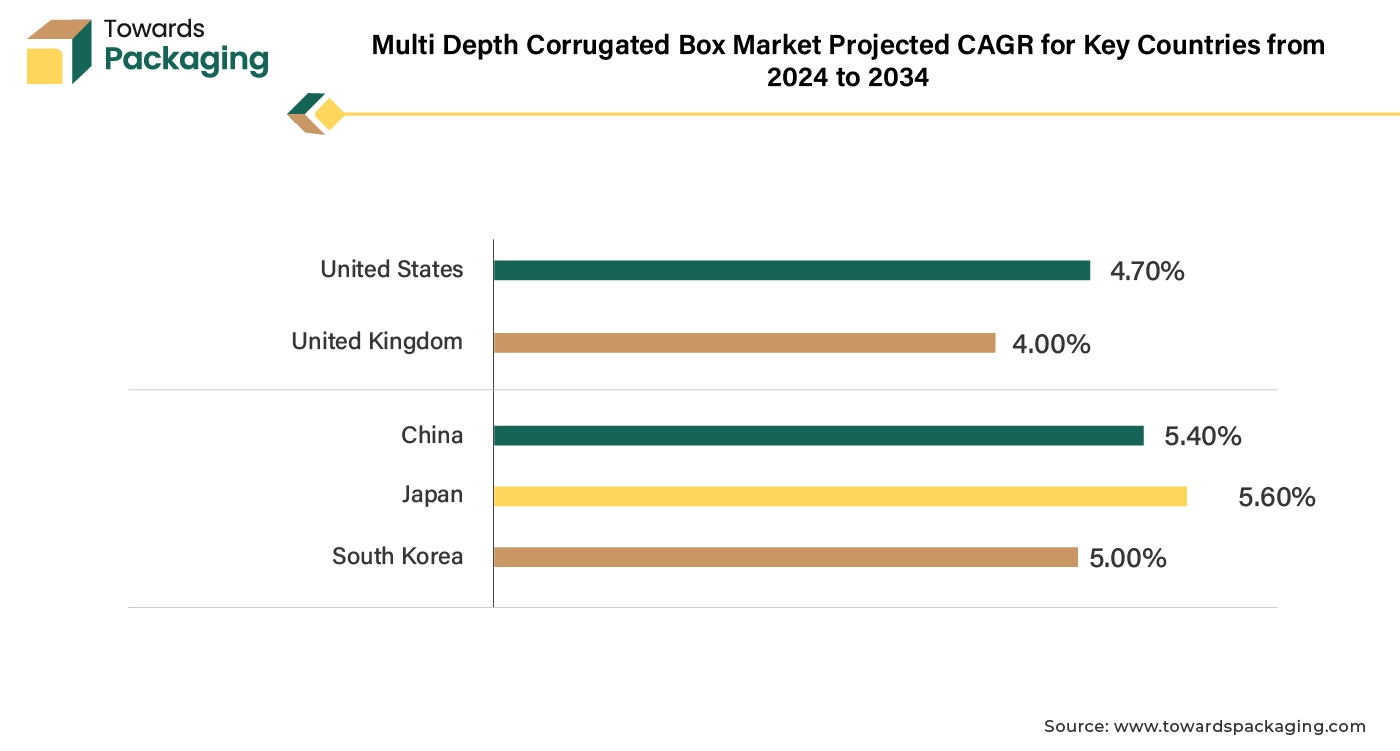

Asia Pacific witness the highest revenue shares for the year 2024. The e-commerce sector in Asia Pacific is expanding rapidly, leading to increased demand for versatile and adaptable packaging solutions that can handle a wide variety of products. Asia Pacific has a diverse manufacturing sector with a wide range of products, including electronics, textiles, and consumer goods. Multi-depth corrugated boxes can accommodate different product sizes and shapes, making them highly suitable for this diverse market. Companies in the Asia Pacific region are seeking to optimize logistics and reduce packaging costs. Multi-depth boxes offer flexibility and reduce the need for multiple box sizes, leading to more efficient inventory management and transportation.

Multi-depth corrugated boxes help reduce material waste and lower overall packaging costs. As sustainability becomes increasingly important, businesses are adopting packaging solutions that align with these goals. With growing consumer expectations for secure and reliable packaging, companies are investing in packaging solutions that offer better protection and presentation, which multi-depth boxes can provide. The key players operating in the Asia Pacific market are focused on investing in the packaging equipment and adopt the advanced technology to meet the rising demand of the multi depth corrugated boxes which is estimated to drive the growth of the multi depth corrugated box market in Asia Pacific region.

For instance,

North America is expected to grow at fastest rate over the forecast period. North America's diverse range of retail and consumer goods needs flexible packaging solutions that can handle various product dimensions and protect items during transit. Rapid urbanization has increased the dependability of consumers over the ready-to-cook food and restaurant food which make the use of multi depth corrugated boxes for packaging of food which is estimated to drive the growth of the multi depth corrugated box market in North America over the forecast period. The surge in online shopping requires packaging solutions that can adapt to various product sizes and shapes, making multi-depth boxes ideal for accommodating different items efficiently.

Multi-depth boxes reduce the need for multiple box sizes, leading to lower inventory costs, simplified logistics, and better overall packaging efficiency. Hence, as the multi depth corrugated boxes offers various benefits to consumers by reducing packaging wastage, demand for it has increased extensively in North America. The key players operating in the North America are focused on launching new manufacturing plant for the development of the corrugated packaging which is estimated to drive the growth of the multi depth corrugated box market in the North America.

For instance,

Capacity

Board Type

Strength

End Use

Region

April 2025

March 2025

March 2025

February 2025