April 2025

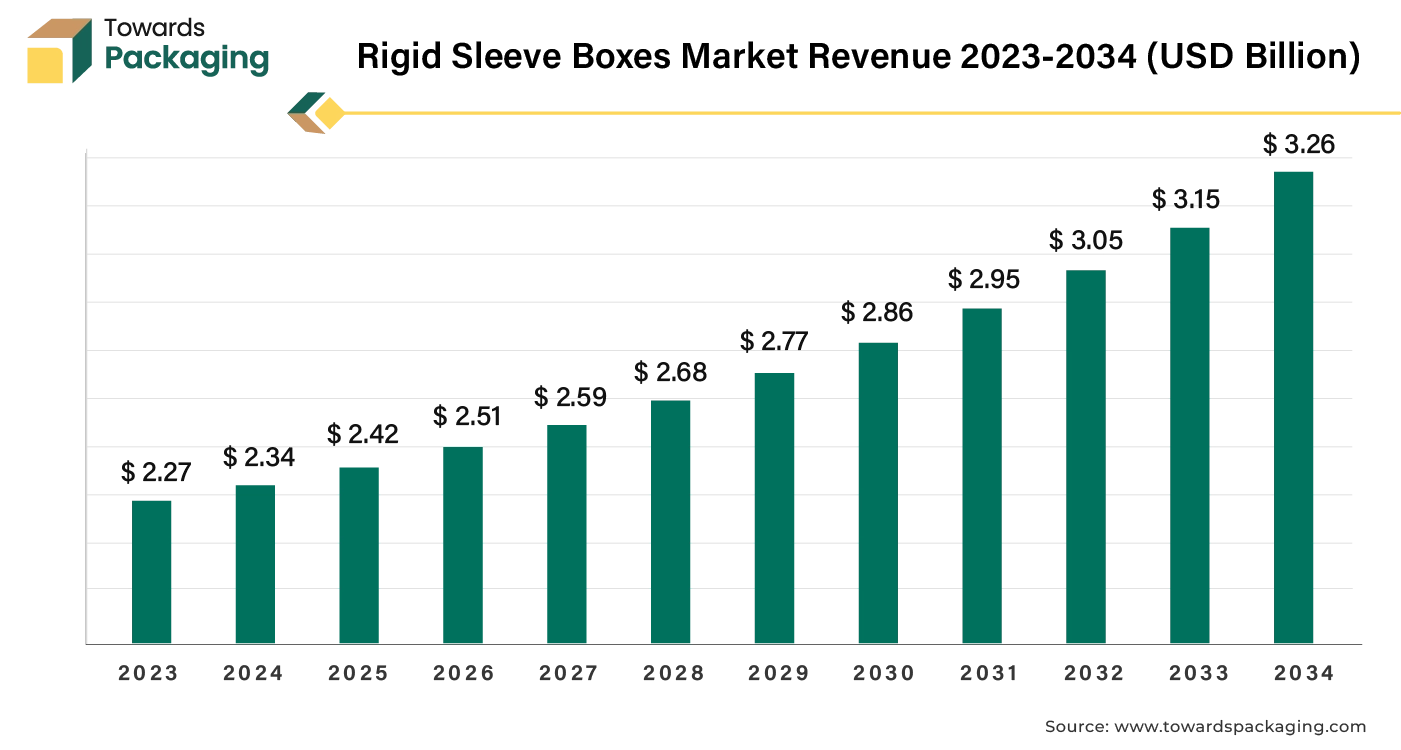

The rigid sleeve boxes market is forecast to grow from USD 2.42 billion in 2025 to USD 3.26 billion by 2034, driven by a CAGR of 3.54% from 2025 to 2034.

Rigid sleeve boxes, also known as slipcases, are a type of packaging where a rigid outer sleeve slides over a separate inner box or container. A rigid sleeves box, often referred to as a rigid sleeve or rigid box, is a type of high-quality packaging used for premium products. They offer a sleek and protective design, often used for high-end products, books, and media items. The outer sleeve provides protection for the inner box, which is ideal for delicate or valuable items. Rigid sleeve boxes can be customized with various finishes, such as embossing, debossing, foil stamping, and spot UV coating, enhancing the aesthetic appeal. The design of rigid sleeve boxes offers a high-end, professional look, making it popular for premium and luxury products. Rigid Sleeve boxes are suitable for various products, including electronics, cosmetics, and collectible items. Overall, rigid sleeve boxes are valued for their combination of protection, presentation, and customizability.

Rigid sleeve boxes are typically made from a high-density paperboard or chipboard covered with a printed or laminated paper. The outer layer can be designed with various finishes such as matte, gloss, or textured. Rigid sleeve boxes are usually constructed from a sturdier material like rigid cardboard or a combination of paperboard and other materials to give it additional strength. The sleeve wraps around the inner box and can slide on and off.

It’s usually designed to fit snugly, providing a secure fit and a polished appearance. Rigid boxes are often used for items that require a high level of presentation and protection. Rigid boxes are designed to be visually appealing on retail shelves and provides robust protection during shipping and handling. Rigid sleeves boxes are highly durable, providing excellent protection for the contents. This helps in safeguarding the product during transit and storage. The high-quality materials and customizable design options make these rigid sleeve boxes visually appealing, enhancing the product’s perceived value.

The sturdy, robust design of these rigid boxes ensures that the contents are protected when being stored or transported. Magnetic closure boxes can be customized by businesses to satisfy their own branding needs. Brands can add foil stamping, offset printing, or digital printing to the boxes' exteriors for a more unique look. Various box materials are available, including paperboard, cardboard, or specialized papers with varied textures and finishes to enhance the visual appeal.

AI can significantly enhance the rigid sleeve boxes industry in several ways, improving efficiency, innovation, and customer experience. AI can assist in creating optimized and innovative designs based on product dimensions and functional requirements. AI algorithms can suggest design improvements or alternatives, leading to more creative and efficient packaging solutions. AI can analyse consumer preferences and trends to offer personalized packaging options. This could involve customized prints, finishes, or unique design features tailored to individual customer needs. AI-driven predictive maintenance can monitor machinery and equipment for signs of wear or malfunction, preventing unexpected breakdowns and reducing downtime in the production process.

With the use of Al-powered design templates and tools, Freepik Al Hub may greatly improve the packaging and label designs creation. With the use of these tools, one may develop designs that are distinctive and seem professional by customizing a vast selection of templates and resources. High-quality design elements are simple to access and use with Freepik Al Hub. Despite the abundance of resources, some sophisticated features and premium content can call for a Freepik membership. Furthermore, while though the Al tools are easy to use, they could not offer as much customization as more sophisticated design software.

The rise in online shopping for consumer electronics has boosted demand for attractive and protective packaging solutions, like rigid sleeve boxes, which enhance the presentation and safety of products during transit. Consumers are increasingly valuing high-quality, aesthetically pleasing packaging, which rigid sleeve boxes provide. This trend is prevalent in sectors like luxury goods, cosmetics, and electronics. Companies are using packaging as a tool for branding and marketing. Rigid sleeve boxes offer customization options that help brands stand out and create a memorable unboxing experience.

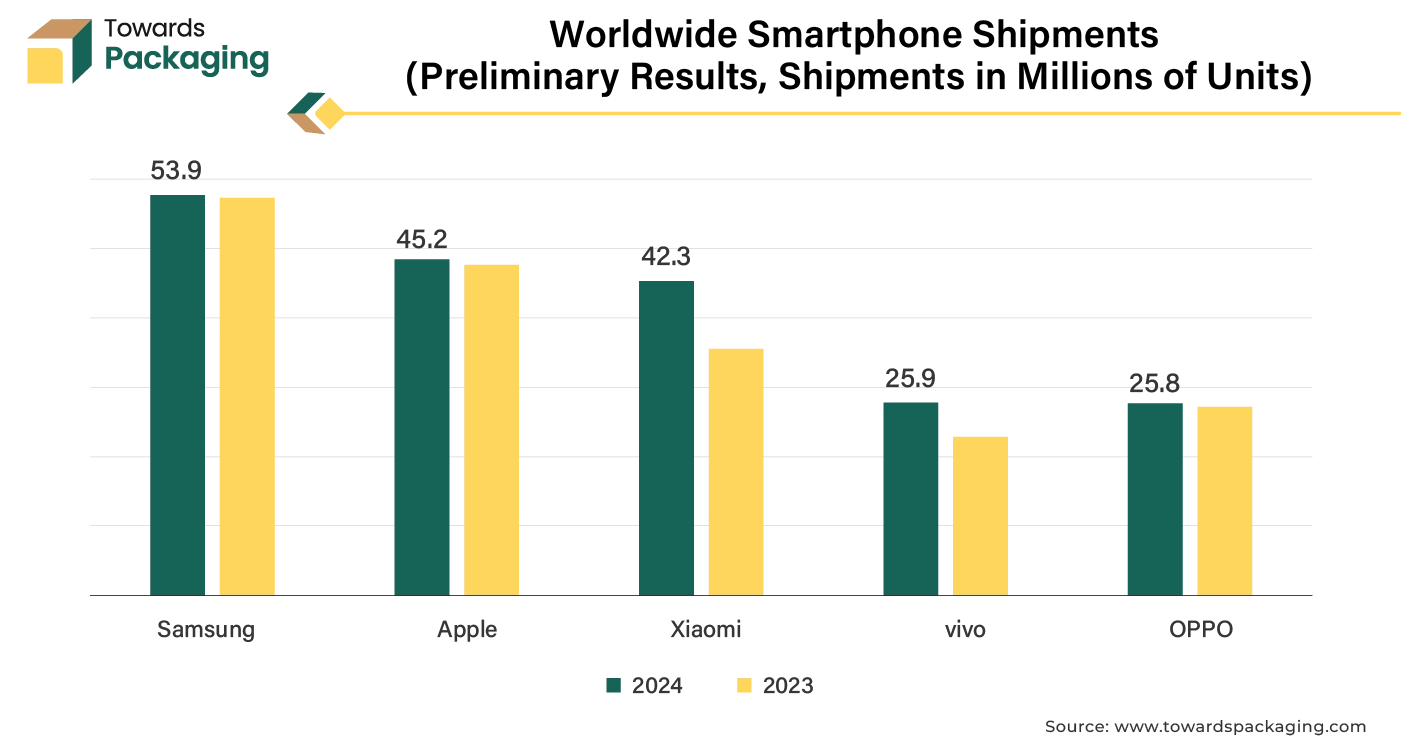

As the consumer goods sector expands, so does the need for innovative and durable packaging solutions to meet varying product requirements. Rigid sleeve boxes, often made from recyclable materials, align with the growing consumer and corporate focus on sustainability and environmental responsibility. Innovations in printing and packaging technology enable more complex and attractive designs, driving demand for rigid sleeve boxes. Expanding international consumer electronics markets increase the need for packaging solutions that can be tailored for diverse cultural preferences and product protection needs. Increasing sales of the smartphone has risen the demand for the rigid sleeve boxes packaging which is estimated to drive the growth of the rigid sleeve boxes market over the forecast period.

For instance,

The key players operating in the market are facing strong competition from the alternative packaging option as rigid sleeve boxes require high manufacturing cost is the main factor hampering the growth of the rigid sleeve boxes market in the near future. The manufacturing of rigid sleeve boxes involves higher material and production costs compared to other types of packaging. This can limit their adoption, especially among cost-sensitive industries. Fluctuations in the prices of raw materials, such as paperboard and plastics, can impact the cost and availability of rigid sleeve boxes, potentially affecting market growth.

Although many rigid sleeve boxes are recyclable, the environmental impact of their production and disposal may pose challenges, especially with increasing regulatory pressures on packaging sustainability. The availability of cheaper and more versatile packaging options, like flexible pouches or standard folding cartons, can limit the market share of rigid sleeve boxes. Some sectors may not fully recognize the benefits of rigid sleeve boxes or may lack awareness of their advantages, which can hinder market adoption. Economic downturns or uncertainty can lead companies to cut back on packaging expenses, affecting the demand for premium packaging solutions like rigid sleeve boxes.

As disposable incomes rise, consumers are more willing to spend on premium and luxury products. Rigid sleeve boxes are often used for high-end items, and increased spending power fuels demand for such packaging solutions. Evolving consumer lifestyles often emphasize aesthetics and brand experience. Rigid sleeve boxes, known for their sophisticated look and feel, align with these preferences, making them a popular choice for products aimed at discerning consumers. Modern consumers often value the overall product experience, including packaging. Rigid sleeve boxes enhance the unboxing experience, catering to the trend of valuing presentation and perceived value. As consumer expectations shift towards personalized and unique products, brands are using customized rigid sleeve boxes to differentiate themselves and appeal to individual tastes

For instance,

The hinged lid segment held the dominating share of the rigid sleeve boxes market in 2024. Hinged lid rigid boxes are a type of packaging that features a sturdy, often high-quality structure with a lid attached by hinges. They are designed for durability and a premium appearance, commonly used for packaging luxury goods, gifts, or high-end products. The hinged lid provides easy access and helps to protect the contents from damage. These boxes are often used in industries like cosmetics, jewellery, and electronics due to their elegant presentation and protective qualities. The hinged lid allows for easy opening and closing, making it convenient for users to access the contents without removing the entire box. The hinged lid rigid sleeve boxes structure provides superior protection for the contents, safeguarding them from damage during handling and shipping.

The combination of a hinged lid and a sleeve offers a sophisticated, high-end appearance, making it ideal for premium products and gifts. These boxes can be customized in various sizes, colors, and finishes to match branding and design preferences. The sleeve provides an additional layer of security, helping to keep the hinged lid securely in place. Due to their durability and attractive design, these hinged lid rigid sleeve boxes are often reused by consumers, enhancing the perceived value of the product inside. The key players operating in the cosmetics market often launch limited edition beauty box which has risen the demand for the hinged lid boxes. Increasing launch of new cosmetics product has risen the demand for the hinged lid rigid sleeve box which is estimated to drive the growth of the segment over the forecast period.

For instance,

The detachable lid segment is estimated to grow at fastest rate over the forecast. Detachable lid rigid sleeve boxes are a type of high-quality packaging that combine functionality and aesthetics. This feature allows the lid to be completely removed from the box, providing easy access to the contents. It often includes a magnetic or tuck-in closure for secure fastening. These boxes are made from sturdy materials like chipboard or thick paperboard, which makes them durable and able to maintain their shape. The detachable lid can be easily customized with different finishes, colors, and designs, allowing for high levels of personalization and brand differentiation. The key players operating in the ice-cream, candy and chocolate market are extensively making use of the detachable lid box for brand marketing which is estimated to drive the growth of the segment over the forecast.

The embossing segment held the dominating share of the rigid sleeve boxes market in 2024. Embossing is a printing process used to create raised or textured designs on rigid sleeve boxes, adding a tactile and visual dimension to the packaging. The first step involves creating a design that includes the areas to be embossed. This design is often created using graphic design software and includes detailed instructions for the embossing process. A metal die is crafted based on the design. This die has a raised pattern that will press into the surface of the box. The die is usually made from brass or copper and is precision-engineered to ensure accuracy.

The rigid sleeve box is prepared for embossing. It is typically made from a sturdy paperboard that can withstand the pressure of the embossing process without damage. The rigid sleeve box is placed between the metal die and a counter die (usually made of a softer material). Heat and pressure are applied to transfer the design from the die onto the box. This creates a raised effect on the box surface. After embossing, the box may undergo additional finishing processes, such as adding foil stamping or applying a final coating. This can enhance the appearance and protect the embossed areas. Embossing adds a sophisticated touch to rigid sleeve boxes, making them stand out with a premium feel and visual interest.

Embossing creates a tactile and visual texture that makes designs stand out, adding a high-quality, elegant touch to the product. It can highlight logos, patterns, and other key elements. The raised effect of embossing conveys a sense of luxury and sophistication, which can elevate the perceived value of the product or brand. Custom embossing helps brands distinguish their packaging from competitors by incorporating unique textures and designs that reinforce brand identity. The raised design provides a tactile experience, which can engage customers more effectively and create a memorable impression. Embossed designs are often more durable than printed designs, as they are less likely to wear off over time.

This ensures that the visual elements remain intact throughout the product’s lifecycle. Embossing can improve readability for important information or branding elements by making them stand out visually, which can be particularly useful for logos and product names. Embossing can be used in combination with other printing techniques, such as foil stamping or spot UV coating, to create a multi-dimensional effect and add further customization options. Overall, embossing is a valuable technique for adding a distinctive, high-quality touch to packaging and printed materials.

The foil stamping segment is estimated to grow at fastest rate over the forecast period. Foil stamping is a printing technique used to add metallic or holographic foil to packaging, such as rigid sleeve boxes, to create a shiny, eye-catching effect. The first step involves designing the artwork, which includes the areas where the foil will be applied. This design must be precise to ensure that the foil adheres correctly to the desired areas. A metal die, often made of brass or copper, is created based on the design. This die has the design etched into its surface and will press the foil onto the box.

The rigid sleeve box is prepared and positioned on the foil stamping press. It is typically coated with a layer of adhesive in the areas where the foil will be applied. A thin layer of metallic or holographic foil is placed between the die and the box. When the press is activated, heat and pressure transfer the foil from its carrier sheet onto the adhesive-coated areas of the box. The die ensures that the foil adheres precisely to the design. After foil stamping, the box may undergo additional finishing processes, such as embossing or coating, to enhance the final appearance and durability.

Foil stamping adds a reflective, metallic sheen that catches light and draws attention, making the packaging stand out. The high-gloss finish of foil stamping adds a premium, high-end feel to the product. Foil stamping can be used to highlight logos, brand names, or key details, reinforcing brand identity. The foil creates a durable, long-lasting effect that resists fading and wear, maintaining the box’s appearance over time. Foil stamping can be combined with other techniques like embossing or spot UV coating for added visual and tactile effects. Foil stamping is a popular choice for creating visually striking and upscale packaging. The foil stamping is popular for packaging luxury items such as high-end cosmetics, perfumes, and fine jewellery.

The metallic or holographic finish enhances the perceived value and sophistication of these products. Foil stamping is frequently used on gift boxes for special occasions like birthdays, weddings, and holidays. The shiny finish adds a touch of elegance and makes the gift feel more special. Electronics such as smartphones, headphones, and other tech gadgets may feature foil stamping to emphasize brand logos and product details, giving a premium feel to the packaging. Any custom packaging designed to stand out or convey a premium message can benefit from foil stamping, making it a versatile option for a range of products.

In essence, foil stamping is used to enhance the visual appeal and perceived value of products across various industries, focusing on items where premium presentation is important. The key players operating in the market are focused on exhibiting the new product launch for foiling purpose which estimated to drive the growth of the segment over the forecast period.

For instance,

The paper and cardboard segment witnessed significant growth in 2024. Paper and cardboard rigid sleeve boxes are sturdy packaging solutions often used for high-quality products. Paper and cardboard rigid box is a slipcover that fits over the inner box. It is often designed with branding and can be printed with custom graphics, making it ideal for a premium presentation. This is a solid, durable box that provides structural support and protection for the contents. It is usually made from thick cardboard or chipboard. These boxes are commonly used for packaging electronics, cosmetics, luxury items, and other products where appearance and protection are crucial. They offer a high level of protection due to their rigid construction and can be customized in terms of size, shape, and design.

Paper and cardboard rigid box construction provides excellent protection for products, reducing the risk of damage during shipping and handling. They offer a premium look and feel, enhancing the visual appeal of the product and contributing to a positive brand image. These boxes can be easily customized in terms of size, shape, color, and design, allowing brands to create unique packaging that stands out. While paper and cardboard rigid boxes offer a premium appearance, paper and cardboard are relatively affordable materials, making them a cost-effective choice for many businesses.

The paper and cardboard rigid sleeve boxes are recyclable and even made from the recycled materials and are themselves recyclable, aligning with eco-friendly packaging trends. They are suitable for a wide range of products, including electronics, cosmetics, luxury items, and food, making them a versatile packaging option. The paper and cardboard rigid sleeve boxes have ability to incorporate distinctive designs, logos, and branding elements helps companies differentiate their products in a competitive market. Focusing on the advantages offered by the paper and cardboard rigid boxes, the key players operating in the market are focused on launching new paper and cardboard rigid sleeve boxes, which is estimated to drive the growth of the segment over the forecast period.

For instance,

The retail boxes segment witnessed the significant growth over the forecast period. Customizable rigid boxes allow brands to create unique and memorable packaging that stands out on shelves and reinforces brand identity. As online shopping continues to rise, there is an increased need for effective packaging that ensures product safety during shipping and provides a positive unboxing experience. Retail boxes offer a platform for branding and marketing, helping businesses stand out on crowded store shelves and attract consumer attention. High-quality, well-designed packaging enhances the overall customer experience, contributing to satisfaction and encouraging repeat purchases.

Retail boxes provide essential protection for products, reducing the risk of damage during handling and transport. The ability to create custom packaging solutions allows brands to tailor their boxes to specific products and market segments, improving their appeal and functionality. In a competitive retail environment, businesses use distinctive packaging to differentiate their products and create a memorable brand experience. Growing consumer preference for eco-friendly packaging is driving demand for retail boxes made from recyclable and sustainable materials. The key players operating in the market are focused on launching the new products in the retail boxes which is estimated to drive the growth of the segment over the forecast period.

For instance,

The food and beverages segment witnessed significant growth in 2024. Rigid sleeve boxes offer a high-quality, attractive presentation that enhances the perceived value of food and beverage products, making them more appealing to consumers. Customizable sleeves allow brands to differentiate their products on crowded store shelves through unique designs, branding, and messaging. The sturdy construction of rigid boxes provides excellent protection for food and beverages, preserving their quality and ensuring they reach consumers in optimal condition. Rigid sleeve boxes offer a superior unboxing experience, which can add to the consumer's satisfaction and increase the likelihood of repeat purchases.

Many rigid sleeve boxes are made from recyclable or biodegradable materials, aligning with the growing consumer demand for eco-friendly packaging. The surface area of both the sleeve and the inner box provides ample space for marketing and nutritional information, which can influence consumer choices. The design of rigid sleeve boxes often makes them easy to open and reseal, which is particularly beneficial for food and beverage products that may be consumed over multiple occasions. Rigid Sleeve boxes can be designed using recycled material that meet specific regulatory requirements for food safety and labeling, helping brands comply with industry standards. The key players operating in the market are focused on adopting inorganic growth strategies like collaboration and partnership to launch new food material brand in new packaging is estimated to drive the growth of the segment over the forecast period.

For instance,

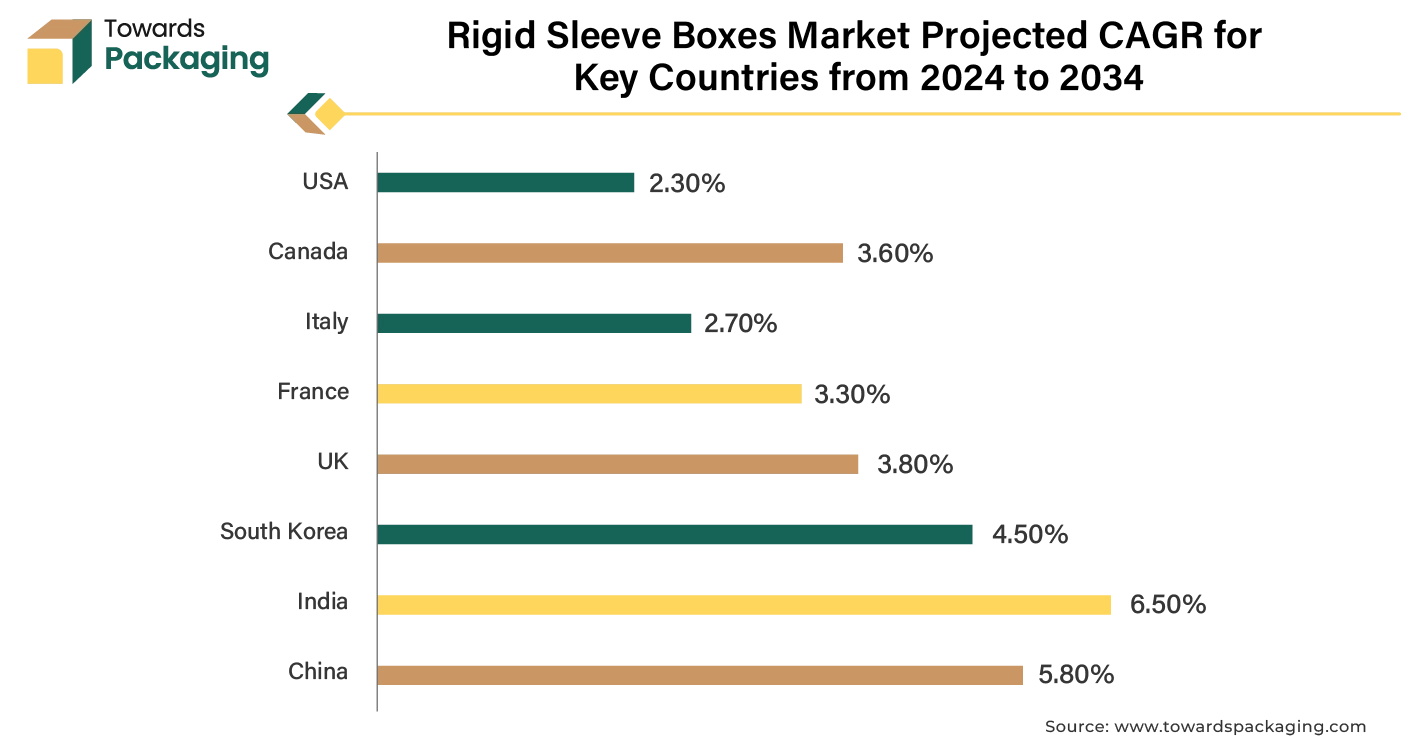

North America witness the highest market share for the year 2024. Growing disposable incomes and a growing population in the US are driving growth in the packaging sector. Luxury rigid box packaging is expected to have a sharp increase in demand in the upcoming years due to increased consumer demand for electronics, clothing, accessories, and consumer products. The tendency is reinforced by the changing inclinations of consumers towards high-end and visually appealing packaging, as it improves both the whole experience with the product and the perception of the brand. North American nations are attracting players in the packaging market due to their simple availability to raw materials and growing organized retail and e-commerce sectors.

The growing purchasing power of American consumers is driving increasing demand for packaged luxury products, which is driving the market's expansion. Innovation and investment in the industry are also fueled by the growing emphasis on sustainability and environmentally friendly packaging. Innovative gift packaging is in high demand during the holiday season in North America, particularly in the United States, since luxury gifting is at its peak.

Notably, the National Retail Federation and the US Census Bureau predicted that retail sales during US holidays increased from US$ 816.70 billion in 2020 to USD 957.30 billion in 2023, highlighting the importance of giving in retail sales. Consumer spending is at its peak during this time, and they have a predilection for premium, eye-catching packaging that makes gifts more enjoyable. Due to the region's embrace of several printing technologies, North America's diversified industries, including food, drinks, and consumer electronics, are embracing a range of luxury packaging solutions. By incorporating cutting-edge printing methods like digital and 3D printing, packaging may be made more individualized and customized to meet the unique requirements of many industries. This broad use of packaging highlights its significance as a key difference in the highly competitive market environment.

Moreover, the key players operating in the market are focused on adopting inorganic growth strategies like partnership and collaboration, to develop and launch rigid sleeve boxes for food and beverages packaging, which is estimated to drive the growth of the rigid sleeve boxes market in the North America region.

Europe is estimated to grow at fastest rate over the forecast period. The market in Europe is seeing innovation in terms of designs and customization options for packaging, which allows brands to differentiate their products and create a unique brand identity. Stringent regulations in Europe regarding packaging and labeling are pushing companies to invest in high-quality, compliant packaging solutions like rigid sleeve boxes. The cosmetic brands in Europe are increasingly focusing on premium packaging solutions to enhance product presentation and improve customer experience. Rigid sleeve boxes offer a high-end appearance and superior protection, which appeals to luxury and high-value products.

The expansion of e-commerce in Europe has driven demand for packaging that not only protects products during transit but also serves as an attractive unboxing experience. Rigid sleeve boxes meet these needs effectively. The key players operating in the market are focused on launching premium limited edition cosmetic or perfumes as branding and marketing strategy which has observed to rise the demand for the rigid sleeve boxes which is estimated to drive the growth of the rigid sleeve boxes market in the Europe.

For instance,

Product Type

Process

Material

Application

End Use

Region

April 2025

March 2025

March 2025

February 2025