April 2025

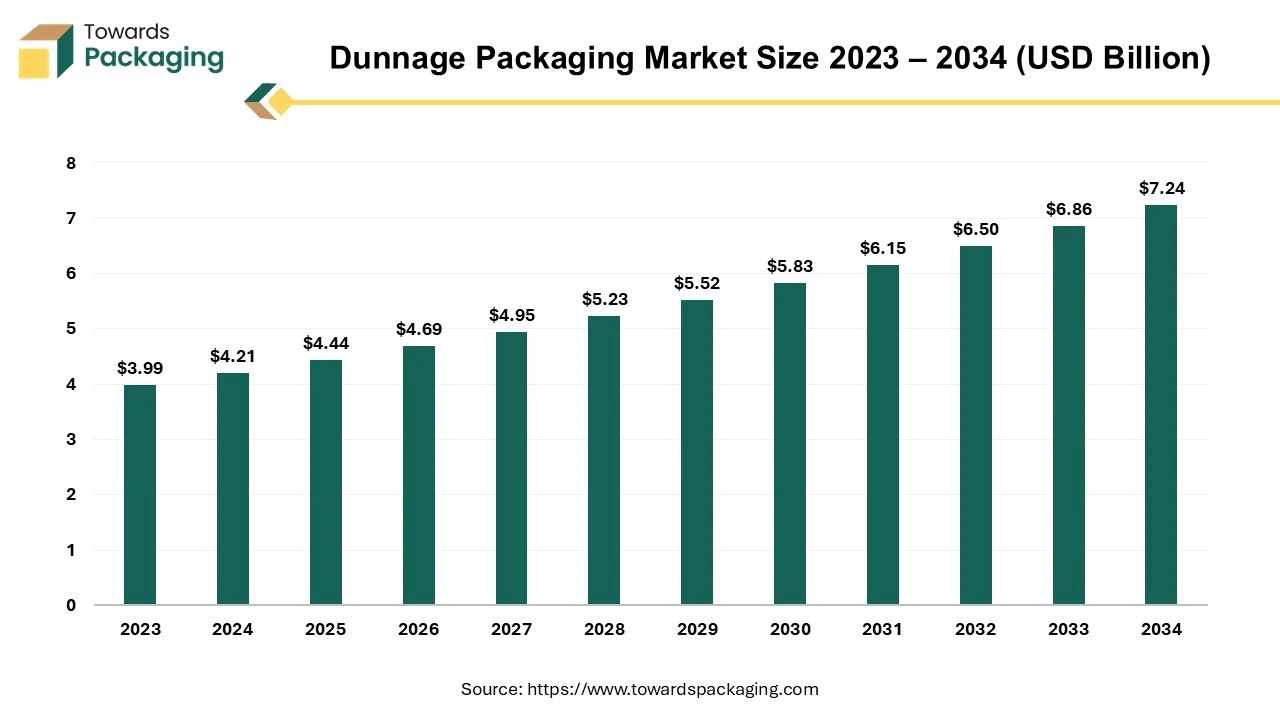

The global dunnage packaging market size was evaluated at US$ 3.99 billion in 2023 and is expected to attain around US$ 7.24 billion by 2034, growing at a CAGR of 5.6% from 2024 to 2034.

The dunnage packaging market is pivotal in the logistics and shipping sector, serving as a linchpin for the secure global transport of goods. As an integral packaging component, dunnage manifests in diverse forms, encompassing airbags, foam inserts, and wooden structures, each playing a crucial role in averting damage arising from the inherent challenges of movement and impact during transit. This market's significance is accentuated by the escalating intricacies embedded in global supply chains, where the efficient and secure transportation of products becomes paramount.

The relentless expansion of global commerce and trade and the rise of e-commerce platforms underscores the indispensability of robust dunnage solutions. Companies engaged in producing and distributing goods increasingly rely on dunnage to ensure that their products reach end-users unscathed. Furthermore, the growing emphasis on product safety during transportation, driven by consumer expectations and regulatory standards, amplifies the market's importance.

Innovation becomes a key driver as the dunnage packaging market continues to evolve. The dynamic nature of supply chain demands, coupled with technological advancements, propels the development of novel dunnage materials and solutions. The market's role extends beyond mere packaging; it serves as a proactive safeguarding mechanism, mitigating risks associated with global logistics complexities and reinforcing the transportation process's reliability.

The packaging industry as a whole is slowly becoming more and more accepting of Artificial Intelligence (AI) technology. This innovative technology often in combination with machine learning (ML) is able to completely alter and elevate efficiency of operations. With AI integration is dunnage packaging, has helped organizations improve efficiency in their operations while helping in reducing total costs. The AI driven systems are being utilized on a wider scale to help optimize design of the packaging and its materials, improvement of the quality and durability and also, help in reducing waste. AI enables that usage of automation technologies which help minimize errors and boost production rates which ultimately helps to quicker turnaround times. Advancements in technology like AI, will help manufacturers create innovative solutions, improve productivity and efficiency and meet demands of eco-friendly and accurate packaging materials like dunnage.

The collective force of consumer expectations and regulatory standards is at the core of the dunnage packaging market's evolution. Consumers, increasingly conscious of the environmental impact of packaging, drive demand for sustainable and efficient solutions. Simultaneously, stringent regulations ensure that companies comply with safety and quality standards in the packaging of goods. This dual influence compels businesses to invest in dunnage solutions that meet regulatory requirements and align with consumer preferences, steering the market towards innovation and responsible practices.

| Trends | |

| E-commerce Surge |

|

| Sustainable Packaging Practices |

|

| Technological Advancements |

|

| Innovation in Dunnage Solutions |

|

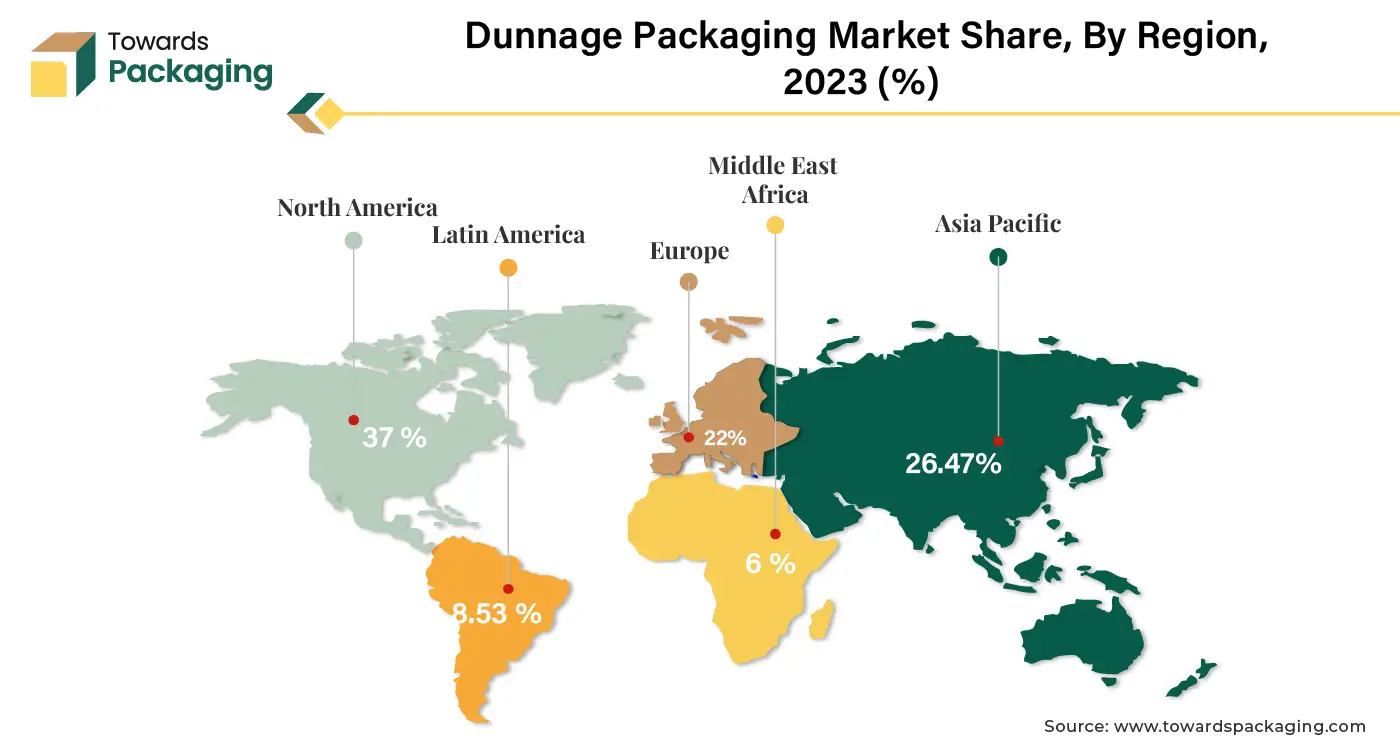

In the intricate tapestry of the dunnage packaging market, North America stands as a beacon of pioneering excellence. The region's pre-eminence is deeply rooted in the robust logistics infrastructure that serves as the bedrock of its efficient transportation networks. This well-established framework allows for seamless movement of goods, positioning North America with 37%, as a key region in the global dunnage landscape.

The thriving e-commerce sector further amplifies North America's dominance. Marked by a substantial increase in online retail transactions, the region experiences a heightened demand for secure and efficient packaging solutions. This surge in e-commerce activities not only underscores the adaptability of North American businesses to evolving market trends but also solidifies their influence in shaping the future of dunnage packaging.

A defining aspect of North America's leadership is its unwavering commitment to adopting cutting-edge packaging solutions. This commitment extends beyond industry norms, positioning the region at the forefront of the market's evolution. The stringent regulatory environment acts as a catalyst, propelling the demand for reliable dunnage packaging. In compliance with regulations that emphasize the safe transportation of goods, businesses in North America prioritize secure packaging practices. This dedication not only ensures compliance but also raises the overall standard of packaging, reflecting North America's commitment to excellence and leadership in the global dunnage arena.

For Instance,

In the dynamic tapestry of the dunnage packaging market, Asia Pacific emerges as a powerhouse, surging ahead with unparalleled industrial dynamism. The region's ascent to the position of the second-leading player is underpinned by a harmonious confluence of factors propelling industrial growth. Rapid industrialization, escalating trade activities, and a burgeoning manufacturing sector collectively contribute to Asia Pacific's commanding presence in the global dunnage landscape.

The exponential economic growth witnessed across Asia Pacific translates into a substantial surge in the volume of goods traversing its expansive transportation networks. This economic dynamism creates a robust demand for effective and reliable dunnage solutions to safeguard products during transit. The region's strategic geographicl positioning and its role as a global manufacturing hub further solidify its position as a pivotal player in the dunnage packaging market.

The evolving preferences of consumers within Asia Pacific form a significant driver shaping the dunnage packaging landscape. As consumers increasingly prioritize products with quality packaging, there is a notable upswing in the demand for robust dunnage solutions. This consumer-driven trend aligns seamlessly with the region's commitment to enhancing overall packaging standards, contributing to the market's sustained growth in Asia Pacific.

The interplay of industrial expansion and evolving consumer expectations positions Asia Pacific as a formidable force in the global dunnage packaging market. The region's unwavering commitment to innovation, coupled with its economic prowess, cements its status as a key influencer in shaping the future trajectory of dunnage packaging on the global stage.

In the ever-evolving realm of dunnage packaging, plastic takes center stage as the undisputed leader, celebrated for its unparalleled versatility and adaptability. The dominance of plastic dunnage materials is underscored by their unique combination of lightweight properties and robust strength, making them an ideal choice for securing goods during transit.

Plastic's ability to mold into various shapes serves as a key differentiator, offering a customized packaging solution tailored to the specific needs of diverse industries. This flexibility allows for the creation of intricate designs that precisely fit and protect products of varying shapes and sizes. The adaptability of plastic dunnage aligns seamlessly with the evolving requirements of modern packaging, catering to the dynamic nature of goods being transported across different sectors.

The market is witnessing a continuous influx of innovation in plastic-based dunnage solutions. Manufacturers are actively exploring and introducing novel applications and designs that push the boundaries of what plastic can achieve in terms of product protection. From inflatable airbags to molded inserts, the versatility of plastic as a dunnage material ensures a comprehensive suite of solutions to address the diverse and evolving needs of industries spanning automotive, electronics, pharmaceuticals, and more.

As the demand for efficient, customizable, and cost-effective dunnage solutions continues to grow, plastic maintains its stronghold as the leading material in the market. Its adaptability not only caters to the current demands of the industry but also positions plastic dunnage materials as a frontrunner in shaping the future landscape of packaging solutions across a myriad of sectors.

Within the expansive realm of dunnage packaging, the automotive sector emerges as the undeniable dominator, steering the course of precise and reliable packaging solutions. The intricacies embedded in the automotive industry's supply chain, coupled with the delicate nature of automotive components, make robust packaging imperative for seamless and damage-free transportation.

The automotive sector's supply chain is a complex web, intricately weaving together manufacturers, suppliers, and distributors. As automotive components traverse this intricate network, they encounter various handling and transportation stages, where the need for dependable packaging becomes paramount. Dunnage materials, particularly foam inserts and molded plastics, play a pivotal role in providing a protective cocoon for these delicate automotive parts.

Foam inserts, with their ability to conform to the contours of components, act as a cushioning layer, absorbing shocks and preventing damage caused by vibrations and impacts during transit. Molded plastics, on the other hand, offer a structured and customized packaging solution, ensuring a snug fit for each component. This precision in packaging is not merely a convenience but a necessity for the automotive sector, safeguarding the integrity of crucial parts and minimizing the risk of defects or malfunctions upon arrival.

In the automotive industry, where precision and reliability are non-negotiable, dunnage packaging becomes an indispensable ally. The seamless integration of foam inserts and molded plastics into the packaging strategy ensures that automotive components reach their destination unscathed, ready to contribute to the assembly of vehicles with the utmost precision. As the automotive sector continues to advance, the role of dunnage packaging in preserving the quality of its components remains pivotal in driving efficiency and excellence.

In the competitive domain of the dunnage packaging market, key players wield considerable influence, shaping industry dynamics. Sonoco Products Company, a leader with extensive experience, focuses on crafting protective solutions for diverse industries, prioritizing innovation for secure transportation. Sealed Air Corporation, a global force, distinguishes itself through eco-friendly packaging technologies, minimizing environmental impact. Automated Packaging Systems specializes in cutting-edge automation for efficient dunnage packaging. Storopack Hans Reichenecker GmbH offers a comprehensive range of protective solutions, solidifying its key player status. FP International, committed to sustainability, excels in manufacturing eco-friendly inflatable packaging systems. Together, these players define industry standards, emphasizing efficiency, customization, and sustainability in dunnage packaging.

Menasha Corporation, DS Smith, Corplex, Dunnage Engineering, Amatech Inc., UFP Technologies Inc., CargoTuff LLC, GWP Group, Ckdpack and Nefab.

By Material

By End Use

By Region

April 2025

April 2025

April 2025

April 2025