April 2025

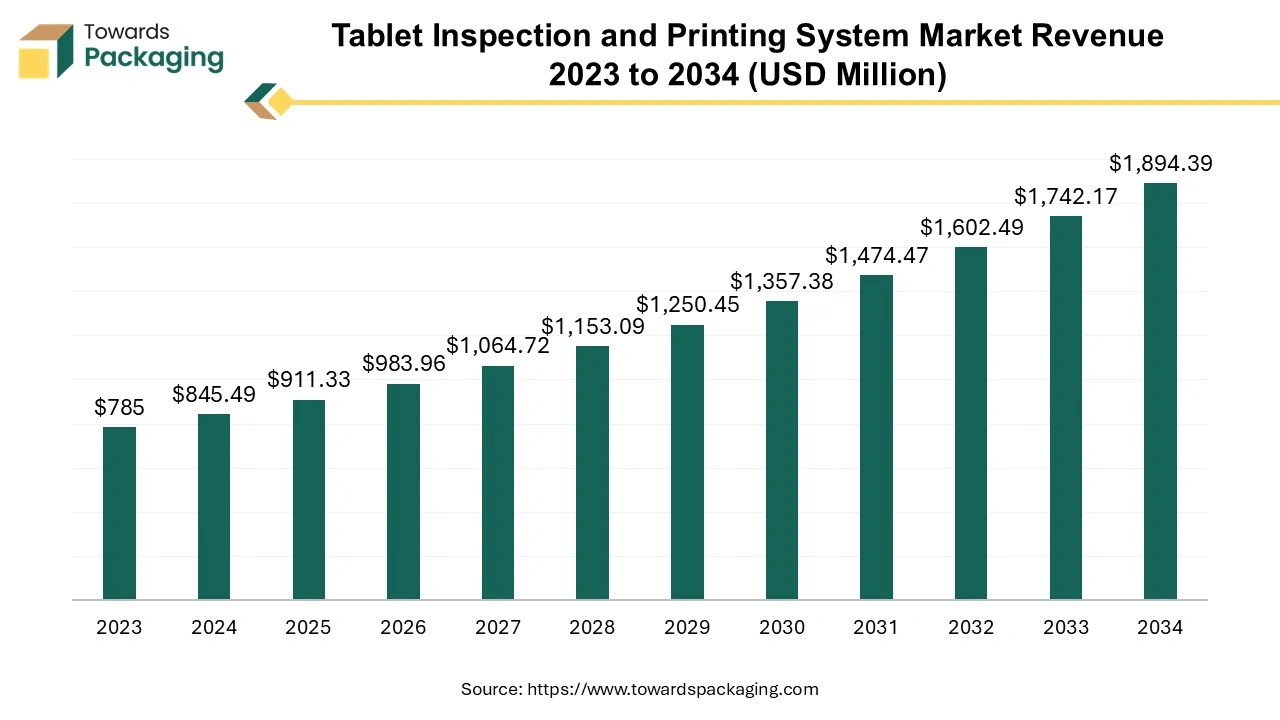

The tablet inspection and printing system market is anticipated to grow from USD 911.33 million in 2025 to USD 1894.39 million by 2034, with a compound annual growth rate (CAGR) of 7.7% during the forecast period from 2025 to 2034.

The market is increasing due to the growing pharmaceutical and healthcare sector requiring the safety of pharmaceutical products, mark labels for identification and many other benefits these factors proliferate the tablet inspection and printing system market.

A tablet inspection and printing system is a machine in which optical illumination and image measurement technology are used while producing tablets to inspect the mismatch, pucker, breakage, surface foreign objects, twisting and staining in tablets. The market is observed transforming significantly to enhance the quality of medicines produced. It is highly used to maintain the integrity of the tablet and to inspect any defective piece while manufacturing. With the strict guidelines for drug safety, the labelling process continuously evolving with the help of automated printing solutions. The major market players are primarily focusing on introducing innovative methods for accuracy and efficiency in manufacturing tablets.

Tablet inspection and printing system market is mainly preferred due to their automated and personalised medication facility. The market is observing noteworthy development due to growing cases of numerous chronic infectious and non-infectious diseases. The development of personalised medicines helps patients to heal fast from several diseases. It is also useful in the tailored medicine market to expand it with more accessibility of tablets. Automated tablet inspection systems use cutting-edge imaging technologies to distinguish defects in real-time, machine vision. The printing aspect of the system is crucial. With the growing traceability and series requirement, medicine companies are implementing advanced printing technology to ensure each tablet is categorized and identifiable.

The tablet inspection and printing system market is constantly experiencing significant improvement due to the expansion of the pharmaceutical industry. Good quality printing is in high demand in medical sectors as it plays a crucial role in producing better quality medicines. Due to such rapid growth in the healthcare sector, the demand for premium-quality and exceptional medication is increasing significantly.

The growing concern for the safety and quality of tablets influences majorly the tablet inspection and printing system. It can ensure the safe production of tablets personalized according to the specific requirements of the patients. Many market players such as R.W. Hartnett, Mutual Corporation, Ackley Machine, Qualicaps, Ace Technologies, and many others are continuously developing advanced quality printing systems to satisfy the growing market demand which promotes the growth of the tablet inspection and printing system market.

The market is getting competitive due to the price of the printing machines getting hiked which hinders the growth of the tablet inspection and printing system. As the pharmaceutical sector looks for customs to reduce expenditures and expand supply chains, they may apply descending price pressure on the printing industry, with the tablet inspection and printing system.

North America witness the highest revenue share for the year 2024. The tablet inspection and printing system market is speedily growing, influenced by the rising demand for enhanced-quality pharmaceutical products and the necessity for acquiescence with strict controlling standards. The shift of companies towards automation is obvious, with companies investing in robotic systems that update the inspection and printing machines. This inclination is demonstrated by partnerships between inspection technology companies and automation experts, intended to decrease human error and increase enhanced quality production.

Well-known players are retorting by expanding their product collections and improving customer service, identifying that providing inclusive support is vital for the retentive market stake. This growth in the market is driven by multiple factors such as rising health issues, telemedicine services on every product, eco-friendly packaging demand, and several others. Rising consumer demand for safe and enhanced-quality printing for better treatment. Governments in countries such as the U.S. and Canada have strict regulations for the tablet inspection and printing system it is kept according to the demand for rising critical cases.

Several major market players are constantly working to provide error-free tablet printing in the pharma industry using a 3D printing system. Medicine brands also use advanced technology for manufacturing these printing that includes a personalised option which is useful for growing health issues.

Europe is estimated to grow at the fastest rate over the forecast period. The rising concern for better quality appropriate medication for the treatment of chronic diseases pushes the tablet inspection and printing system market. The growing culture for personalised medication facilities has surged the demand for premium quality tablet printing systems. Medicine brands are investing extensively in their printing to attract healthcare experts to suggest these medicines that promote their business which results in the growth of the tablet inspection and printing system market.

Personalised medication with an enhanced printing system for personalised care is highly in demand for which brands invest huge amounts and experience better customer response. This facility is to meet the demands of the healthcare sector in precise ways, especially for brands introducing home delivery services of products.

By type, the high-speed segment led the tablet inspection and printing system market in 2024. It is evolving rapidly as the demand for efficient and accurate pharmaceutical manufacturing is rising significantly. It fulfils the demand for personalized medication systems by producing enhanced printing machines in the market. This system includes the inkjet printing and vision inspection to meet the regulatory standards.

By application, the large companies segment led the tablet inspection and printing system market in 2024. This type is useful for the pharmaceutical sector for accuracy in labelling and packaging of medicines. With the incorporation of machine learning and AI in this market, large companies with high investment produce enhanced quality tablets.

By Type

By Application

By Region

April 2025

April 2025

April 2025

April 2025