April 2025

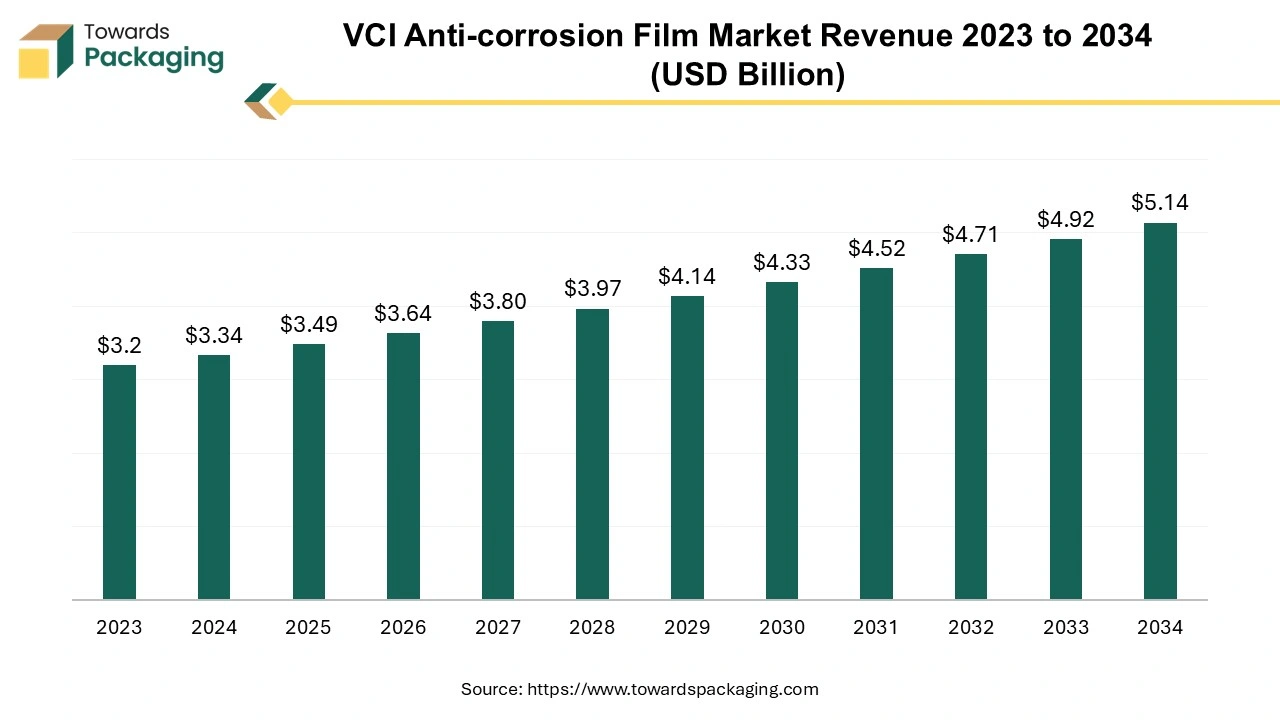

The VCI anti-corrosion film market is set to grow from USD 3.49 billion in 2025 to USD 5.14 billion by 2034, with an expected CAGR of 4.4% over the forecast period from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The market is expanding due to the expansion of food business worldwide. With the increasing demand for food, there is a high demand for storing hot or cold foods, such as desserts, salads, and sandwiches. However, storing food in containers with VCI anti-corrosion film prevents contamination of these food items.

VCI anti-corrosion film protects metal things from corrosion and rusting. It not only offers a physical barrier to keep metal parts sparkling and free from humidity, contaminants, and dust, but vapor corrosion inhibitor film also releases its rust-eradicating VCI to form a cover of the shield on the upper layer of the metal, which has only 2-3 particles thick. VCI anti-corrosion film can be factory-made in a range of forms, such as sheets, rolls, and VCI bags or tubing. It is a clean, dry, easy-to-use packaging material.

With the rising urbanization, there is a huge demand for construction work, such as building for both commercial and residential purposes, roads, and various other purposes. These need iron, aluminum, and several metal materials, which need to be kept covered and protected as these metals get damaged when left in contact with moisture. In such conditions, VCI anti-corrosion films play a vital role in protecting them from corrosion.

By wrapping with such films, metals can be protected from moisture or any damage caused by the external atmosphere. These VCI films are generally made of materials such as polyethylene, which has chemical formulations with some unique combinations to protect it from damaging the external environment. This unique chemical combination results in the best quality protection of the metals and is also eco-friendly, attracting many customers to use such films. As the construction work increases, the demand for iron and other metals increases, which ultimately boosts the VCI anti-corrosion film market.

There is a huge demand for sustainable products in all sectors, which enhances the scope of innovation for market players in numerous fields. This rising demand for eco-friendly films has compelled the market to bring such innovations, and with such advancements in the market, the opportunity also grows significantly. Corrosion is a major problem faced by all sectors when it comes to using metals for several purposes, and to avoid corrosion, metal components need to be protected. Several companies are introducing enhanced-quality films.

These anti-corrosion films prevent metals from any kind of damage, making them a suitable choice for keeping things fresh. Market players are bringing innovative ideas to develop biodegradable, recyclable, inexpensive anti-corrosion films, which are suitable for a wide range of metal surfaces. Customization in terms of thickness and quality of films is in high demand for which market players invest huge amounts. Rising technological advancements in manufacturing technology of VCI anti-corrosion film further create immense opportunities in the market.

Excessive use of VCI anti-corrosion film sometimes leads to quality compromise. Also, these wraps need to be used carefully, as improper wrapping can cause air bubbles, which can further damage the product due to remaining in contact with moisture. Some medical issues, such as irritation in the eyes, are observed in people who are directly using it to wrap products. These factors hinder the growth of the VCI anti-corrosion film market.

Asia Pacific held the highest revenue share of the market in 2024. This is mainly due to the increasing demand for high-quality, safe, and corrosion-free packaging solutions. Governments in countries such as India, Japan, China, Thailand, and South Korea implemented strict guidelines for the manufacturing of VCI films. This region has a high demand for durable packaging that is driving the anti-corrosion film market. Regional players are focusing on producing biodegradable and recyclable films to meet the varying demands of consumers.

North America is expected to witness the fastest growth in the VCI anti-corrosion market over the forecast period. With the rising production of automotive and aerospace components, there is a high demand for anti-corrosion film to keep all these components safe and away from damage. Regional market players are making efforts to develop products, which can keep the integrity and quality of products intact. Moreover, the rising production of metals further fuels the regional market growth.

By type, the below 25-micron segment led the VCI anti-corrosion film market in 2024. These wrapping films have an airtight packaging quality that makes them suitable for keeping products new. The rising demand for sustainable wrapping in numerous sectors has enhanced the development of these films.

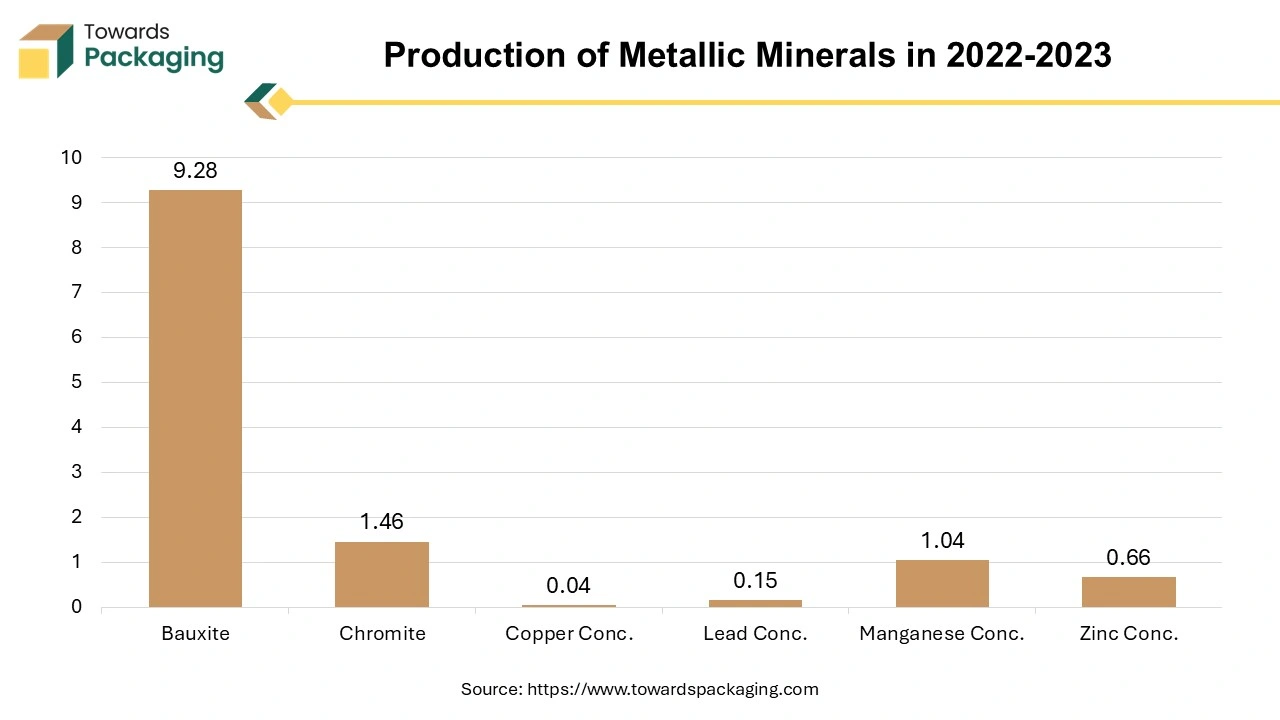

The mining and metallurgy segment dominated the market in 2024 by application. The increased production of metals led to the demand for anti-corrosion films that prevent damage if left in contact with moisture for a long time. In mining areas, bulk amounts of metals are extracted from the earth's core, which requires safe storage as there is a high risk of corrosion.

By Type

By Application

By Region

April 2025

February 2025

February 2025

February 2025