March 2025

.webp)

Principal Consultant

Reviewed By

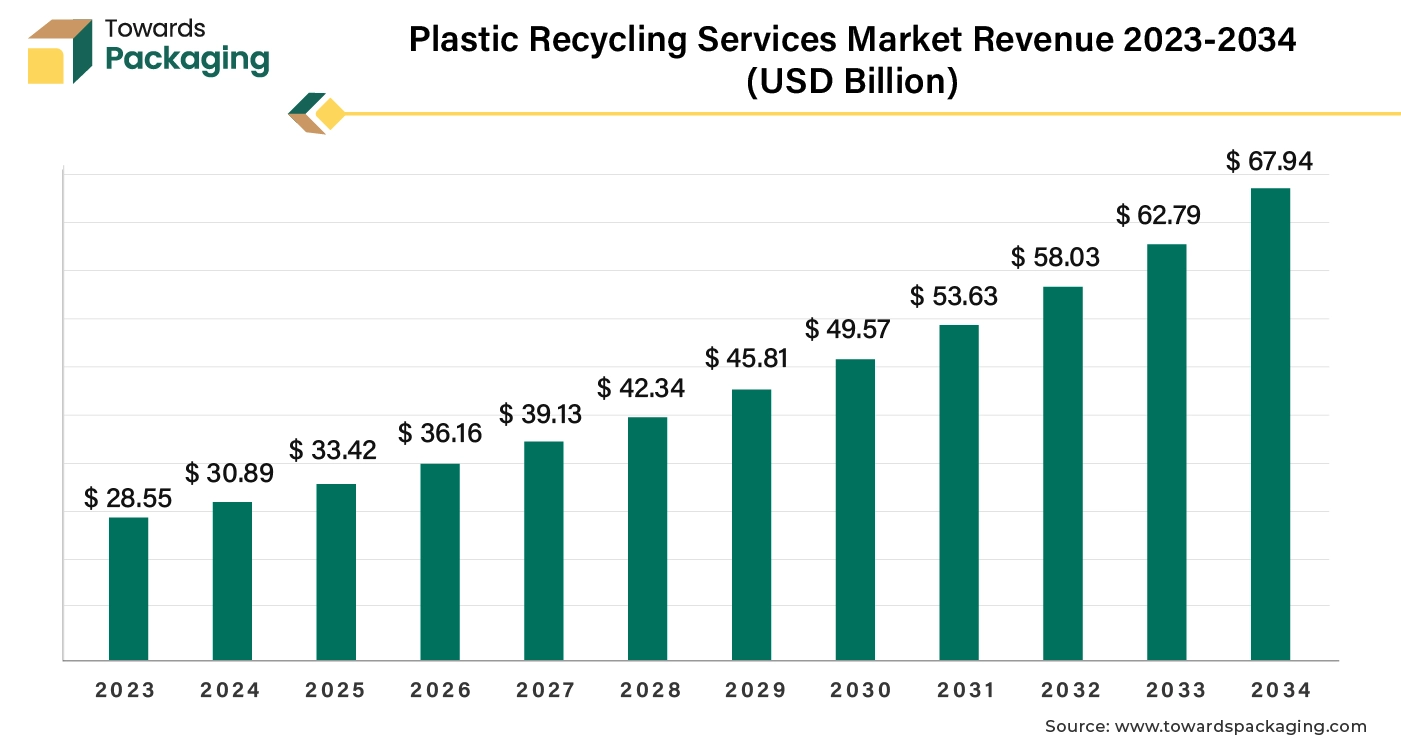

The global plastic recycling services market size reached US$ 30.89 billion in 2024 and is projected to hit around US$ 67.94 billion by 2034, expanding at a CAGR of 8.20% during the forecast period from 2025 to 2034. The rising demand for sustainable practices as well as growing awareness about the eco-friendly options amongst consumers is expected to surge the demand for plastic recycling services market.

Growth in the circular economy emphasizes recycling as a way to reduce waste and conserve resources. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for plastic recycling which is estimated to drive the global plastic recycling services market over the forecast period.

Plastic recycling is the process of collecting and processing plastic waste to develop new products. This involves breaking down used plastic items, cleaning them, and then reprocessing them into raw materials that can be used to manufacture new plastic goods. The aim is to minimize plastic waste, conserve resources, and reduce environmental impact. The plastic recycling is either done by mechanical process or chemical process. Mechanical process plastic recycling involves physically breaking down plastic waste into smaller pieces without altering the chemical structure of the plastic.

This typically includes steps like sorting, shredding, washing, and melting the plastic. The resulting pellets can then be used to create new products. This method is efficient and widely used, as it helps reduce the amount of plastic waste and conserves resources. Chemical plastic recycling is a process that breaks down plastic materials into their fundamental chemical components. This method differs from mechanical recycling, which reprocesses plastics without changing their chemical structure.

Plastic recycling services encompass a range of activities aimed at collecting, processing, and repurposing plastic waste. Plastic recycling services play a crucial role in reducing landfill waste, conserving resources, and lowering greenhouse gas emissions associated with plastic production. By promoting recycling, these services contribute to a circular economy where materials are reused rather than discarded. In summary, plastic recycling services are vital for managing plastic waste, reducing environmental impact, and promoting sustainable practices in product development and consumption.

Increasing public concern about plastic pollution and its impact on ecosystems encourages recycling initiatives and sustainable practices. Many companies are adopting sustainability targets, driving demand for recycled materials to meet their environmental commitments and reduce carbon footprints. Initiatives to lower plastic waste are rising due to growing environmental concerns, such as the impact of plastic pollution on ecosystems and human health. Increased awareness of climate change and sustainability drives both public and governmental demand for change. Additionally, businesses are recognizing the economic benefits of sustainable practices, leading to innovations in materials and recycling technologies. Ultimately, these initiatives aim to create a more sustainable future.

In Europe, packaging production uses about 20 million tons (Mt) of plastic (or 40% of all plastics), and 6 Mt of HDPE (10%) is produced annually. Closing the recycling loop for garbage including sensitive HDPE packaging is the primary problem. It is essential to adhere to EU standards and customer demands for hazardous compounds, organoleptic requirements like color and odor, and contaminant migration. To ensure that the packaging is produced in a way that is both safe for the consumer and consistent with the company's branding, the package producer must adhere to certain mechanical and physical specifications. All packaging must be circular in order to combat plastic pollution in waste management, lower CO2 emissions, and lessen reliance on fossil fuels.

The key players operating in the market are facing challenges in getting accurate technology for recycling the plastic waste, which is observed to restrict the growth of the plastic recycling services market. High operational costs for plastic recycling and low market prices for recycled plastics can deter investment. Inefficient recycling processes and lack of advanced technologies hinder effective recycling. Inconsistent regulations and lack of support can impede market development. Low awareness and participation in recycling programs can limit supply. Contaminated plastics complicate the recycling process and reduce quality. These factors combined create significant barriers to expanding the plastic recycling services market.

Plastic harms the environment in several ways: it contributes to pollution in oceans and landfills, threatening wildlife through ingestion and entanglement. Microplastics can contaminate soil and water sources, affecting ecosystems and human health. Plastics also take hundreds of years to decompose, leading to long-term environmental degradation. Furthermore, the production and incineration of plastics release greenhouse gases, exacerbating climate change. Research and development activities to improve plastic recycling are growing due to the urgent need to address environmental challenges posed by plastic waste. Innovations aim to enhance recycling technologies, making them more efficient and cost-effective.

Additionally, there's a push for developing biodegradable alternatives and better waste management practices. Increased regulatory pressures and consumer demand for sustainable products further motivate R&D efforts in this area. Ultimately, these activities seek to create more effective solutions for managing plastic waste. Increasing research initiatives Increasing research and development initiatives to reduce plastic waste, is estimated to create lucrative opportunities for the growth of the plastic recycling services.

There has been rapid technological development in the last few and recycling technology is also constantly evolving. Technology has enabled recycling methods to be branched out and not depend on one particular technology. Innovations in recycling technology like chemical recycling is proving itself to be an effective method to properly process non-degradable plastic. Such technology is a solution that breaks down plastic into its chemical components which allows high quality recycled material that can have wider applications. With AI and automation, the efficiency and consistency in quality and operations reduces any contamination in recycling process which leads to bigger volume of recyclable materials. The technological developments in the recycling technology are ongoing and an opportunity for the plastic recycling services market.

For instance,

TOMRA's GAIN technology, was renamed GAINnext to honour the product's noteworthy advancement, can now overcome all of these difficulties by improving the AUTOSORT units' sorting capabilities even further. This allows the units to recognize objects that are difficult or, in certain situations, even impossible to classify using conventional optical waste sensors.

The mechanical recycling segment held a dominant presence in the plastic recycling services market in 2024. Mechanically recycling process is widely utilized for plastic waste as it's cost-effective, energy-efficient, and can handle various types of plastics. The process involves shredding plastics, washing them, and re-melting to create new products. It helps conserve natural resources by reusing existing materials, reducing the need for virgin plastic production, which is resource-intensive. The energy required for mechanical recycling is generally lower than that for producing new plastics from raw materials, resulting in a smaller carbon footprint. By diverting plastic waste from landfills, mechanical recycling significantly reduces environmental pollution and promotes a circular economy.

Mechanical recycling can be more cost-effective compared to chemical recycling processes, making it an attractive option for many recycling facilities. It even facilities can create local jobs in collection, sorting, and processing, contributing to the economy. The mechanical recycling process is relatively straightforward and can be easily implemented, which helps in scaling recycling initiatives.

Chemical recycling segment is expected to grow at the fastest rate in the plastic recycling services market during the forecast period of 2024 to 2034. Chemical recycling involves converting waste plastics into monomers or other useful chemicals, which can then be used to produce new plastics or other products. This process can handle a wider variety of plastics, including those that are often not recyclable through mechanical methods. Chemical recycling can process a wider range of plastics, including multi-layered materials and those contaminated with food or other substances.

The end products can be of higher quality compared to mechanically recycled plastics, as they can be reconstituted into virgin-like materials. It helps create a closed-loop system where waste plastics are transformed back into raw materials. The monomers or chemicals produced through chemical recycling can be used to create new plastics, synthetic fibers, or even fuels, contributing to a more sustainable materials lifecycle. Increasing launch of the chemical recycling technology for plastic waste is estimated to drive the growth of the segment over the forecast period.

For instance,

The plastic bottles segment accounted for a significant share of the plastic recycling services market in 2024. PET bottles are highly recyclable, and there is a rising market for recycled PET. PET is one of the most readily collected and recyclable polymers since it is widely used in beverage and water bottles. In order to encourage consumers to return used bottles for recycling, several regions have implemented curbside collection programs and bottle deposit schemes. Demand is also being driven by the growing use of PET in textiles and packaging as companies look to decrease plastic waste and achieve sustainability targets. As part of their environmental commitments, big businesses, especially in the food and beverage industry, have committed to utilizing a sizable amount of PET in their packaging.

Europe region is held the largest share of 48.50% in the plastic recycling services market in 2024. The rapid growth of the plastic recycling services market in Europe can be attributed to stringent regulations promoting sustainability, increasing consumer awareness about environmental issues, and technological advancements that enhance recycling efficiency. Additionally, initiatives from the European Union aimed at reducing plastic waste and promoting a circular economy further drive demand for recycling services.

For instance,

The key players operating in the Europe are focused on investing in plastic recycling services, which is estimated to drive the growth of the plastic recycling services market in near future. As well as increasing initiative to launch to plastic recycling service center in Europe, is estimated to drive the growth of the market.

For instance,

Asia Pacific region is anticipated to grow at the fastest rate in the plastic recycling services market during the forecast period. The rapid growth of the plastic recycling services market in the Asia Pacific region is driven by rising industrialization, increased plastic consumption, and growing environmental awareness. Governments are implementing stricter regulations on plastic waste management, while advancements in recycling technology and infrastructure support efficient processing. Additionally, urbanization and a burgeoning middle class are amplifying the demand for sustainable practices. The key players operating in the Asia Pacific region are taking initiative to support plastic recycling which is estimated to drive the growth of the plastic recycling services market in Asia Pacific region.

By Process

By Type

By Region

March 2025

March 2025

February 2025

February 2025