April 2025

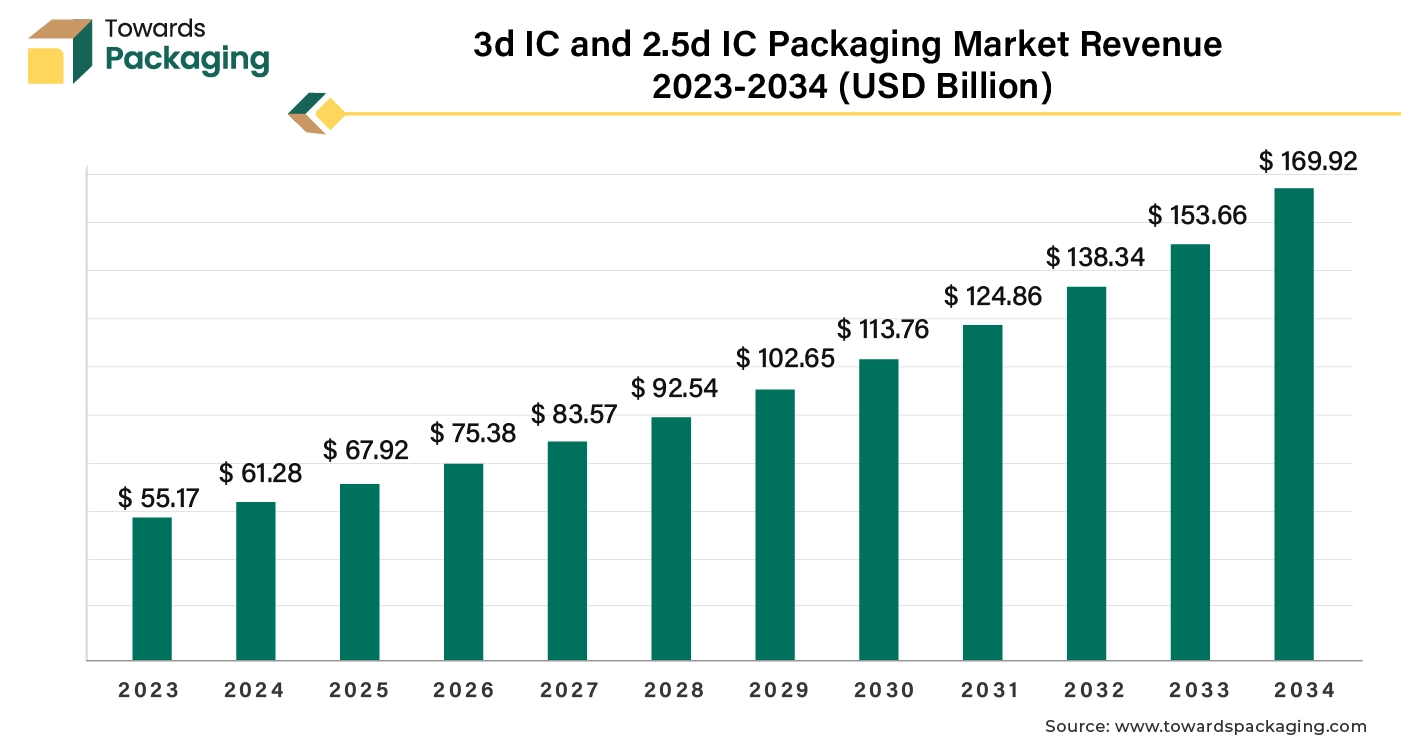

The 3D IC and 2.5D IC packaging market is expected to grow from USD 67.92 billion in 2025 to USD 169.92 billion by 2034, with a CAGR of 10.85% throughout the forecast period from 2025 to 2034.

3D and 2.5 ICS offer a more compact form factor and minimize power consumption compared to traditional packaging methods, which is important for mobile gadgets and other space-constrained applications. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing 3D IC and 2.5D IC packaging which is estimated to drive the global 3D IC and 2.5D IC packaging market over the forecast period.

The packaging technology of 2.5D and 3D is used to package several integrated circuits in one package. To achieve a very high die-to-die connection density, two or more active semiconductor chips are arranged side by side on a silicon interposer in a 2.5D configuration. Die stacking is used in 3D structures to incorporate active chips for the shortest connectivity and smallest package footprint. 2.5D and 3D have become more and more popular as the best chiplet integration* platforms in recent years because of their advantages in obtaining very high package densities and good energy efficiency.

The packaging technology of 2.5D and 3D are cutting-edge methods used to improve semiconductor devices' efficiency, functionality, and performance. In order to create a three-dimensional structure, many layers of silicon wafers or dies are stacked vertically in 3D IC packaging. Logic, memory, and analogue integrated circuits (ICs) can all be integrated into one package thanks to this stacking. allows for greater capability in a smaller package. Performance is improved via shorter interconnects between layers, which shorten the time a signal travels. It is possible to boost data bandwidth between components by stacking layers. The global packaging industry size is growing at a 3.16% CAGR.

3D IC packaging involves stacking multiple layers of silicon wafers or dies vertically, creating a three-dimensional structure. This stacking allows for the integration of different types of ICs (such as logic, memory, and analogue) within a single package.

2.5D IC packaging involves placing multiple dies side-by-side on a single interposer, which is a layer of silicon or other material that contains the interconnections between the dies. This creates a “half” 3D effect by arranging the dies horizontally and connecting them through the interposer.

Artificial Intelligence can help find and create new materials that will improve IC packaging performance and dependability. Artificial Intelligence (AI) can find interesting candidates for novel materials by evaluating performance data and material attributes. The 3D and 2.5D IC packaging sector can achieve better performance, increased efficiency, and improved quality by utilizing AI, which will spur additional innovation and growth in this area.

AI algorithms can analyze and optimize the design of 3D and 2.5D ICs, improving performance, reducing power consumption, and minimizing thermal issues. AI can automate complex design tasks and find optimal configurations faster than traditional methods. AI can predict and identify potential yield issues in the manufacturing process by analyzing data from previous production runs. This helps in adjusting parameters to improve yield rates and reduce defects. AI-driven simulations can help in designing better thermal management solutions for 3D ICs. AI models can predict heat distribution and identify potential hotspots, leading to more effective cooling solutions.

By examining patterns in data from testing and inspection procedures, artificial intelligence (AI) can improve fault identification and diagnosis. This enhances dependability by making it possible to identify flaws and anomalies more quickly. The efficiency and precision of 3D and 2.5D IC testing and validation procedures can be improved by using artificial intelligence (AI).

Complex test data can be interpreted by AI algorithms, which can also verify that ICs fulfill performance and quality requirements. AI can improve production procedures in manufacturing by evaluating data from production machinery and sensors. This may result in decreased downtime, increased overall efficiency, and better process control.

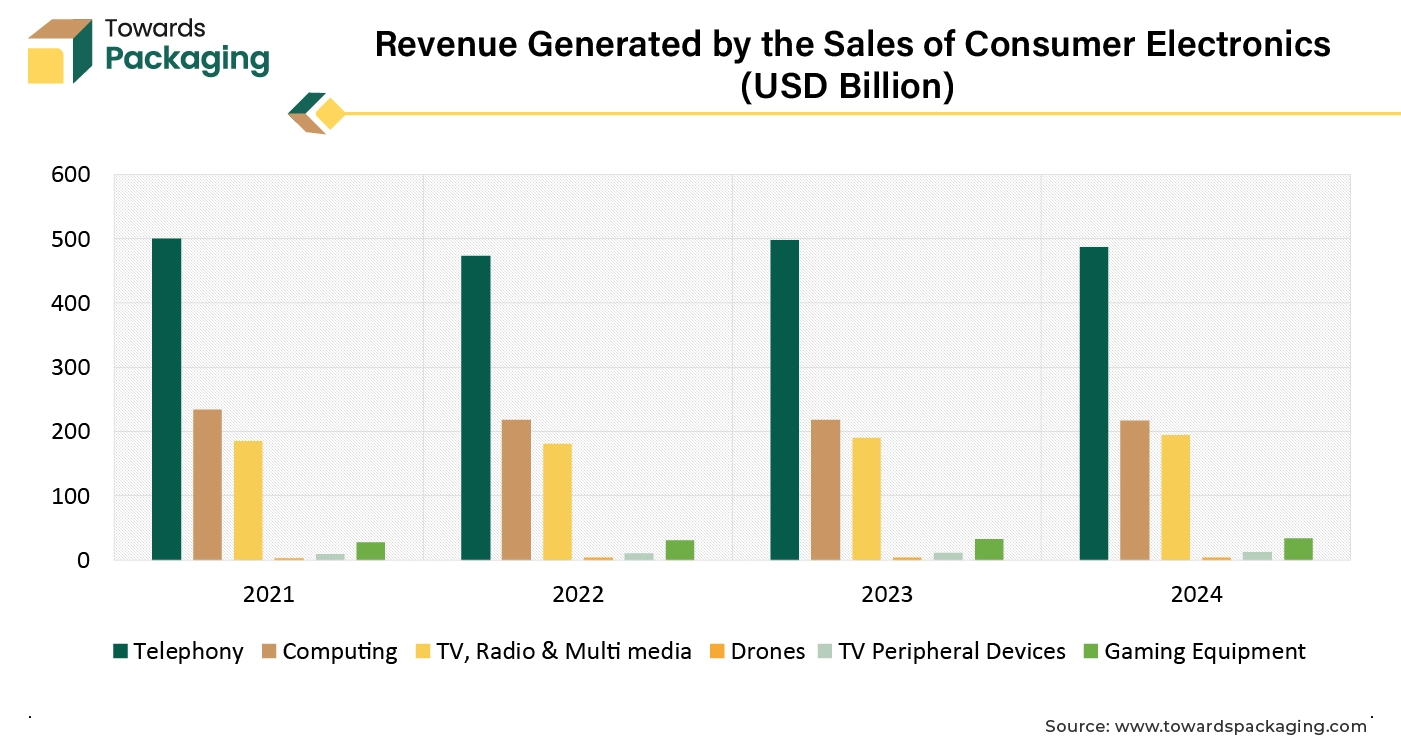

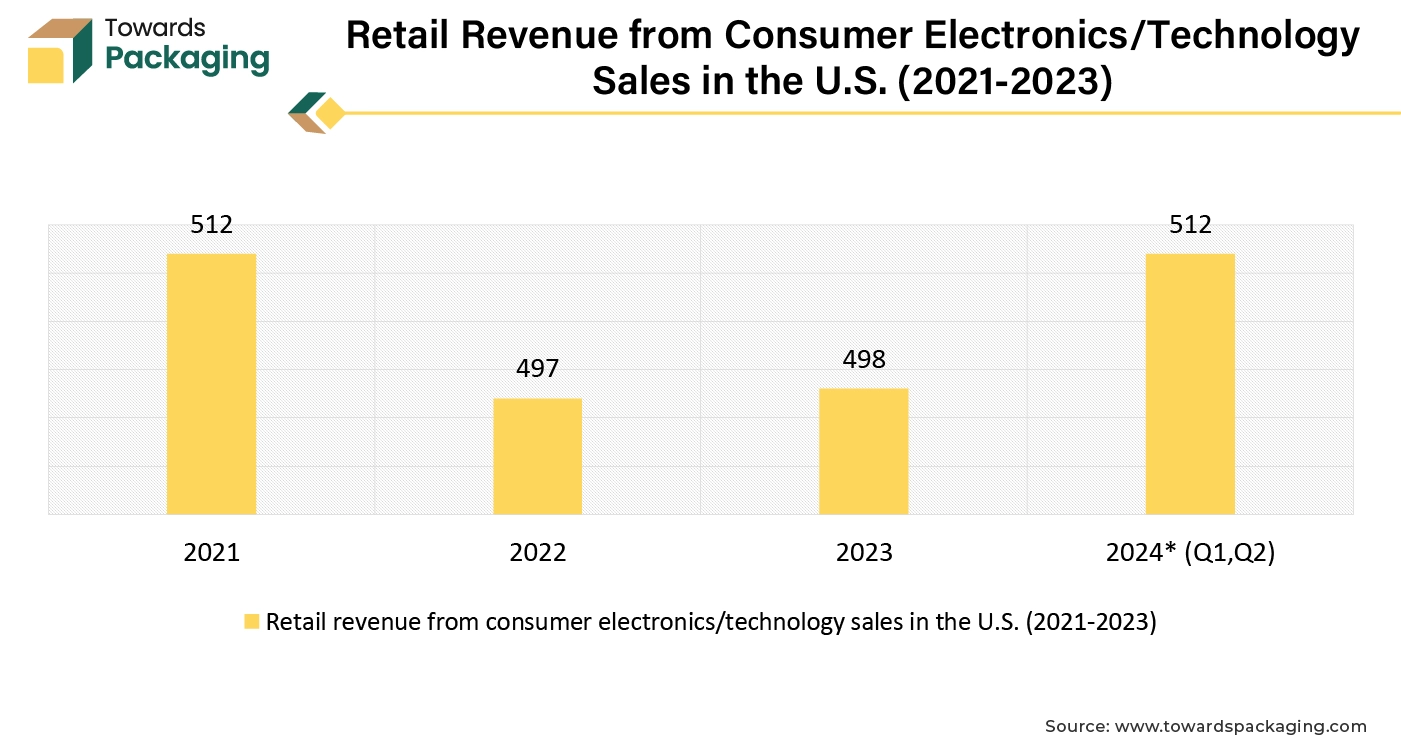

Rapid industrialization and urbanization has given boom to consumer electronics demand and encouraged the development of new gadgets to be used in day-to-day life. Continuous innovation in electronics leads to new and improved devices with enhanced features, performance, and capabilities. This drives consumers to upgrade to the latest technology. The increasing trend of streaming services, gaming, and other digital media expands the demand for high-quality consumer electronics like TVs, audio systems, and gaming consoles. The demand for smartphones, tablets, and other portable devices continues to grow as they become essential tools for communication, work, and entertainment. The proliferation of the Internet of Things (IoT) and smart devices has developed an expanding ecosystem of connected electronics, from smart homes to wearable technology, boosting demand.

Increased interest in smart home technologies, such as voice assistants, smart thermostats, and security systems, drives the demand for various connected devices. Expanding middle-class populations and improved infrastructure in emerging markets contribute to higher demand for consumer electronics as more people gain access to these technologies.

The key players operating in the market are facing challenges during manufacturing as well as reliability and yield concerns which is restricting the growth of the 3D IC and 2.5D IC packaging market. 3D and 2.5D IC packaging require expensive materials and technology, which may discourage adoption, particularly for businesses with limited resources.

The manufacturing of 3D and 2.5D integrated circuits (ICs) entails complex procedures like fine pitch interconnects and through-silicon vias (TSVs), which are difficult and demand sophisticated machinery. Controlling heat dissipation in closely spaced 3D integrated circuits is difficult and can have an impact on performance and dependability. It is a major engineering problem. Because of the intricacy of the 3D and 2.5D ICs, it can be challenging to achieve high yield and ensure long-term reliability.

Due to rapid development in automotive industry and aim to reduce CO2 emission, the electric vehicles are adopted by the most of the people. Smart infrastructure and smart city projects are increasingly becoming a focus for urban development and modernization. Advancing intelligent transportation systems (ITS) to improve traffic management, reduce congestion, and enhance public transportation through real-time data and connectivity.

The key players are engineering and ddeveloping smart grids to enhance the efficiency and reliability of electricity distribution, incorporating real-time monitoring and automated control systems to manage energy consumption. The key players operating in the market are focused on adopting inorganic growth strategies like partnership to develop smart infrastructure for electric vehicle charging on public streets which is estimated to create lucrative opportunity for the growth of the 3D IC and 2.5D IC packaging market over the forecast period.

For instance,

With Siemens' Innovator3D IC software, developing a digital twin of the entire semiconductor package assembly is made easier with a single data model for design planning, prototyping, and predictive analysis. The mechanical design, testing, signoff, implementation, multiphysics analysis, and release to manufacture are all guided by this cockpit. It facilitates quick "what-if" investigation while recognizing, averting, and resolving issues before the implementation of a thorough design by combining power, signal, thermal, and mechanical stress analysis methods. Subpar outcomes or expensive, time-consuming downstream rework can be avoided with this shift-left methodology.

The 3D wafer-level chip-scale packaging (WLCSP) segment held a dominant presence in the 3D IC and 2.5D IC packaging market in 2024.

The MEMS/Sensors segment accounted for a notable share of the 3D IC and 2.5D IC packaging market in 2024. MEMS and sensors often require integration with additional electronic components (e.g., signal processing units, power management circuits). 3D IC and 2.5D IC packaging enable compact, high-density integration, minimizing the overall footprint and supporting for more compact device designs. Microelectronics, microactuators, and microsensors are the functional parts of MEMS.

Accelerometers, gyroscopes, digital compasses, inertial modules, pressure, humidity, microphones, and smart sensors are a few examples of the sophisticated components of MEMS. MEMS and sensors often require integration with additional electronic components (e.g., signal processing units, power management circuits). 3D IC and 2.5D IC packaging enable compact, high-density integration, reducing the overall footprint and allowing for more compact device designs.

A compact design is essential to all of these components and sensors. As a result, a lot of sensors have begun using 2.5D and 3D IC packages. These benefits make 3D and 2.5D IC packaging particularly advantageous for MEMS and sensor technologies, where performance, size, and integration are critical. The key players operating in the market are focused on launching new MEMs/Sensors, which has observed to raise the demand for the 3D IC and 2.5D IC packaging and estimated to drive the growth of the segment over the forecast period.

For instance,

The consumer electronics segment registered its dominance over the global 3D IC and 2.5D IC packaging market in 2024. The rapid innovation in technology such as innovations and improvements in processing power, display quality, and connectivity (e.g., 5G), drives need for new and next generation electronic devices. The augmentation in adoption and innovation of smart devices, including wearables, smart home gadgets, and smart devices, is expanding the market as consumers seek integrated and connected experiences. Increasing advancement in wearable tech, such as fitness trackers and smartwatches, are creating new market segments and driving additional consumer interest.

For instance,

Asia Pacific region dominated the global 3D IC and 2.5D IC packaging market in 2024. Asia-Pacific region is home to leading semiconductor manufacturers and foundries, such as Samsung and Taiwan Semiconductor Manufacturing Company (TSMC). These companies are at the forefront of advanced packaging technologies, including 3D IC and 2.5D IC. The Asia-Pacific region benefits from lower production costs and a well-established supply chain, making advanced packaging technologies more economically viable for large-scale production. Many countries in Asia Pacific region are focused on developing smart city and smart infrastructure due to rise in adoption of the 3D IC and 2.5D IC packaging, which is estimated to drive the 3D IC and 2.5D IC packaging market over the forecast period.

For instance,

More than 89% of Japan's GDP is generated by the automobile industry. Japan is actually the third-biggest automobile manufacturer in the world! However, Japan has not embraced zero-emission vehicles (ZEVs) as quickly as several other Asian nations have. Japan's economic stability will be impacted by the success or failure of its automobile industry as the world transitions more quickly to ZEVs. This will have a big impact on Japan's still-emerging role in the changing global EV scene.

North America region is projected to host the fastest-growing 3D IC and 2.5D IC packaging market in the coming years. North America, particularly the U.S., is home to major technology and semiconductor companies like Intel, AMD, and NVIDIA, which are leading the development and adoption of advanced packaging technologies, including 3D IC and 2.5D IC. North America has a well-established ecosystem that includes leading packaging technology providers, material suppliers, and equipment manufacturers, which supports the growth and adoption of advanced packaging solutions.

Many North American companies are forming strategic partnerships and investing in advanced packaging technologies to gain a competitive edge and address evolving market needs. The region has a strong demand for high-performance computing solutions, including in data centers, AI applications, and high-end consumer electronics, which drives the need for advanced packaging to meet performance and power efficiency requirements.

By Packaging Technology

By Application

By End User

By Region

April 2025

April 2025

April 2025

April 2025