April 2025

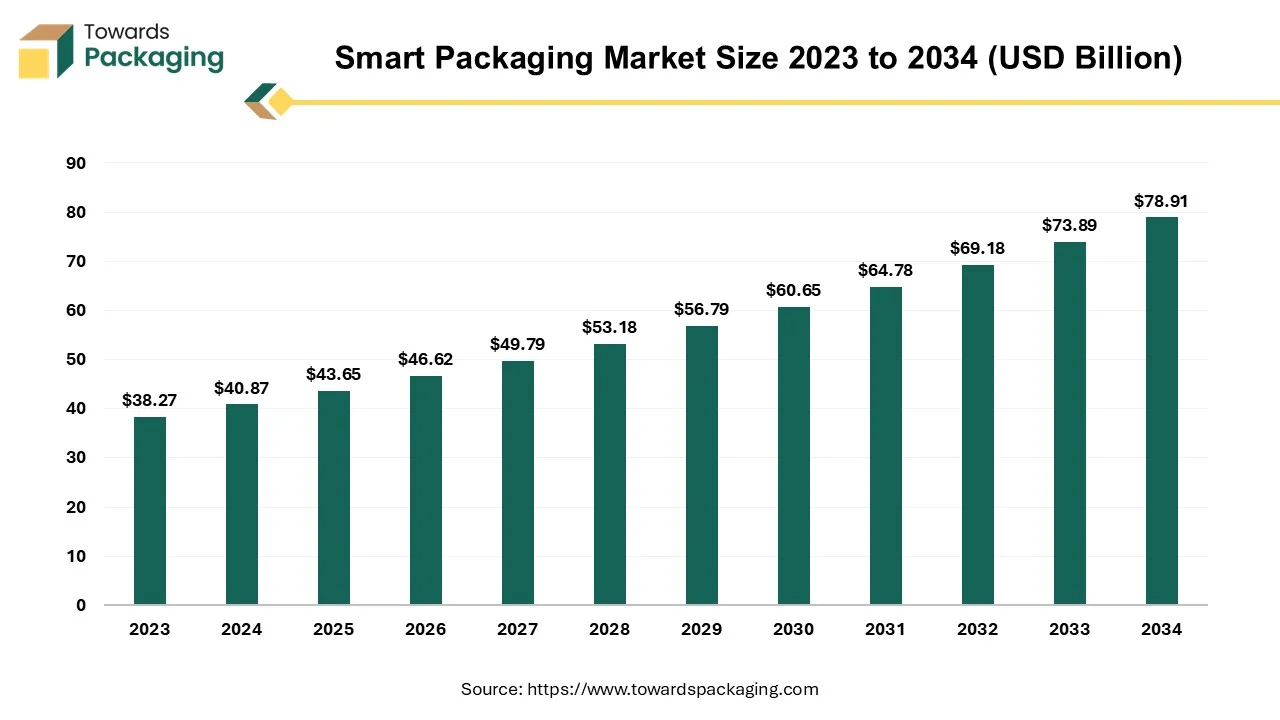

The global smart packaging market is forecasted to expand from USD 43.65 billion in 2025 to USD 78.91 billion by 2034, growing at a CAGR of 6.8% from 2025 to 2034.

In order to interact with customers, confirm authenticity, and track a product's path, smart packaging, also referred to as connected packaging, uses distinctive barcodes, QR codes, or other digital identities. What was once a straightforward package being a digital tool thanks to this unmatched technology, which also provides customers and brand owners with insightful information. Each package has a unique code put on it using digital variable data printing.

Even when the product is in circulation, the brand owner has complete control over the digital experience that each code links to and can change whenever they like. Every pouch has an own digital identity thanks to these serialized codes. This can help protect against diversion from the gray market and counterfeiters. Because every box has a unique number, you can track every pouch or bag along the supply chain and use a mobile interface to give each customer a personalized digital experience. Additionally, marketers can link particular data to a particular package because each cach product has a unique code.

Active packaging extends shelf life by controlling moisture, oxygen, and microbial growth. Intelligent packaging provides real-time info on product status, freshness indicators, time-temperature indicators, and leak detection. Rising demand in food & beverage, pharmaceuticals, and cosmetics. For instance, color-changing indicators to show freshness of perishable food.

Use of QR codes, RFID sensors, NFC tags, and barcodes to enable track & trace capabilities. The smart packaging offers supply chain transparency and enhances consumer engagement. Smart packaging connected to smartphones and cloud-based platforms for real-time monitoring. For instance, scan a code to check product authenticity and trace the origin.

Growing emphasis on biodegradable, recyclable, and compostable materials. For sustainable package option use of bio-based polymers combined with smart functionalities is done. Brands are leveraging smart packaging to communicate sustainability efforts to consumers. For instance, recyclable smart labels and compostable active packaging films.

Smart packaging enables personalized marketing, promotions, and product information. AR (Augmented Reality) experiences via packaging for enhanced brand interaction. Gamification and storytelling through interactive packaging. For instance, AR-enabled wine bottles that tell the brand story when scanned.

Increasing counterfeiting in luxury goods, pharmaceuticals, and beverages. Smart packaging with tamper-evidence, blockchain, and unique serialization improves product security. The smart packaging enhances consumer trust and safeguards brand reputation. For instance, blockchain-based verification of pharmaceutical packaging.

Strong demand for compliance monitoring, like reminding patients to take medication. Smart blister packs, dose tracking, and temperature-sensitive labels. The smart packaging helps in reducing medical errors and ensuring proper storage conditions. For instance, medicine packs that send reminders via mobile apps.

Technological advances are bringing down the cost of sensors, NFC, and RFID solutions. Smart packaging is becoming more cost-effective for mass-market adoption. Entry of new players and growing investments are accelerating this trend.

This entails integrating sensors into packaging to keep an eye on variables like pressure, temperature, and humidity. For example, retailers and customers can be informed by time-temperature indications if a product has been exposed to conditions that potentially affect its quality. To ensure that perishable items like food and medications stay safe and effective throughout their lifecycle, this is especially important.

AI analyzes supply chain and usage data to recommend eco-friendly materials and efficient packaging designs. Optimizes package sizes and weights to reduce environmental impact and shipping costs. For instance, AI suggests a switch to compostable materials based on environmental data and compliance requirements. AI tracks product usage patterns and environmental conditions to optimize lifespan. The integration of AI assists in designing packaging that aligns with expected consumer behavior and end-of-life disposal. For instance, AI analyzes opening frequency of smart packaging to determine freshness and recommend restocking.

AI-enabled visual inspection systems verify the integrity of packaging during production. Detects defects, mislabelling, or tampering before products reach shelves. For instance, AI cameras on the production line flag packaging defects in milliseconds, ensuring consistent quality. In pharmaceuticals and food packaging, AI monitors and analyzes data from biosensors. The artificial intelligence integration ensures compliance with health standards and alerts in case of deviations. AI alerts healthcare providers if temperature-sensitive medication packaging detects unsafe storage conditions.

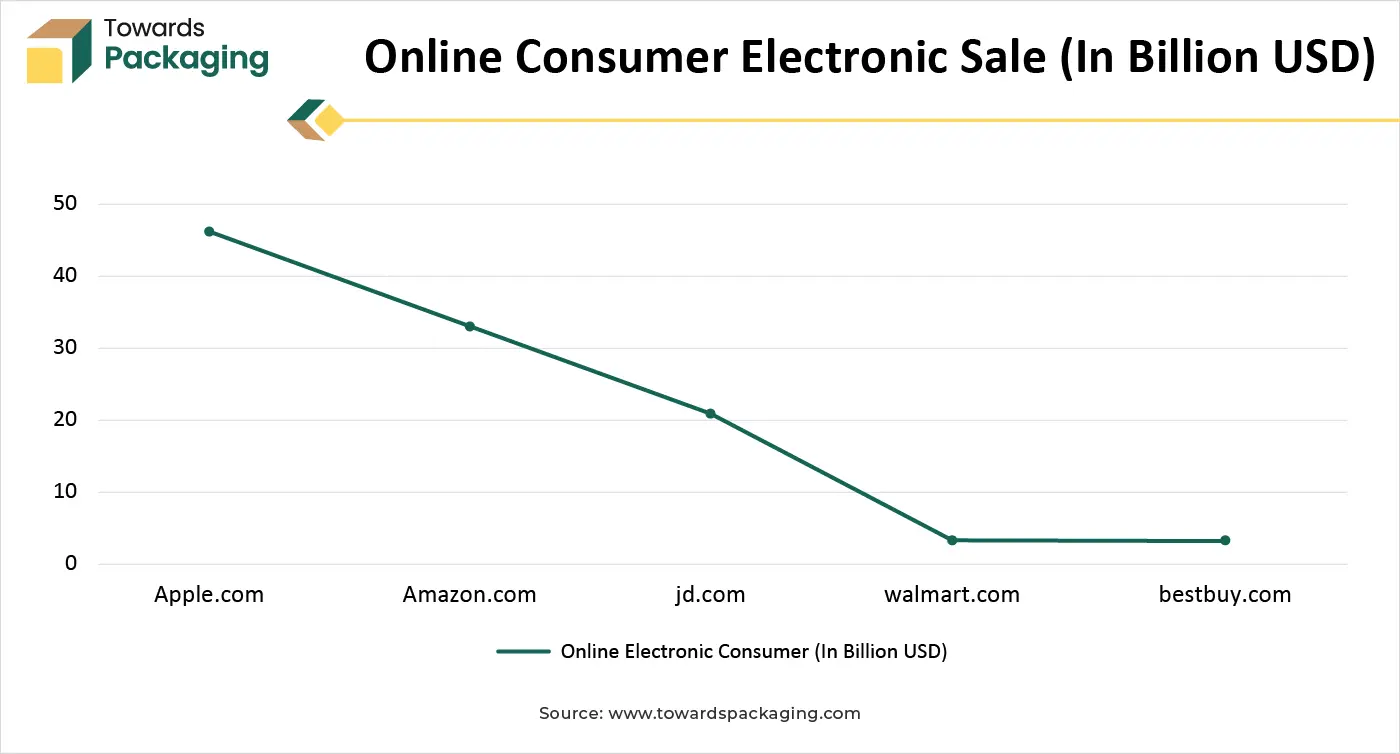

Due to the busy life-style and modernization the online shopping trend is quickly adopted by the people. Smart packaging improves inventory management, condition monitoring and real-time tracking during transit, which is crucial for online retail and logistics. Modern consumers prefer interactive packaging that offers convenience, product information, and brand engagement (e.g., scannable QR codes). Smart packaging can minimize food waste (e.g., time-temperature indicators alert consumers when food spoils). Hence, due to expansion of e-commerce platform has estimated to drive the growth of the smart packaging market over the forecast period.

The key players operating in the smart packaging market are facing issue due to limited consumer awareness and complex supply chain, which has estimated to restrict the market growth over the forecast period. As smart packaging collects and transmits data, there are concerns about cybersecurity and consumer data privacy, especially in the EU where GDPR is strict. Companies fear the risks of data breaches and the complexity of compliance. Smart components need to survive harsh environments (heat, cold chains, heat, moisture).

Opportunities for interactive marketing using AR, QR codes, NFC to deliver personalized content, product traceability, or loyalty rewards. Consumers increasingly want transparency and story-telling from brands (e.g., ethical sourcing, origin tracking). Smart packaging generates valuable data about consumer behaviour, logistics efficiency, and product usage. The market players can leverage this data for better decision making, predictive maintenance, and targeted marketing.

The active packaging segment held a dominant presence in the smart packaging market in 2024. Active packaging is a kind of packaging that works with the product to preserve its quality and increase its shelf life. For instance, antibacterial compounds that stop the growth of microorganisms and oxygen scavengers that stop oxidation. For the food business to minimize waste and guarantee that products stay fresh from manufacture to consumption, active packaging is crucial. The active packaging enhances the product quality by improving hygiene and safety. The purpose of active packaging is to react to variations in the environment both within and outside the container. There are many different methods utilized in active packaging because the goal of active packaging might vary based on the food product.

The food & beverages segment registered its dominance over the global smart packaging market in 2024. Perishable products like dairy, meat, seafood, and fresh produce need smart packaging that prolongs freshness. Smart packaging reduces food waste by extending usable life. Active packaging solutions absorb oxygen, control moisture, or release antimicrobials. Consumers and regulators increasingly demand transparency about food origin, handling, and safety. Smart packaging with QR codes, RFID, NFC helps track products from farm to table. For instance, scannable packaging that shows the entire journey of seafood from catch to store. Smart packaging ensures safe delivery by monitoring temperature, humidity, and handling. Smart packaging offers interactive experiences, providing instant product details via smartphones. Smart packaging helps optimize material use and promotes recyclability. Smart packaging enables easy adherence by providing real-time monitoring and traceability. Brands use smart packaging for enhanced consumer engagement, storytelling, and premium positioning.

North America region held the largest share of the smart packaging market in 2024, owing to well developed and supportive infrastructure for smart packaging. North America region, is home to major technology innovators in IoT, printed electronics, AI, and sensor technologies. For instance, companies like 3M and Avery Dennison are leaders in smart labels and RFID technologies. Northern American consumers are highly eco-conscious and want to know the full journey of the products they purchase. North America has one of the pharmaceutical markets globally.

In North America, food waste is a major issue-smart packaging assists to monitor freshness, encouraging responsible consumption and minimizing waste. North America has an advanced, tech-integrated supply chain ecosystem. Retailers present in North America are shifting to smart retail environments, where smart packaging integrates with IoT and POS systems.

U.S. smart packaging market is driven as the major key players for smart packaging technology are situated in U.S. country. The consumers in U.S. are increasingly demanding traceability, freshness indicators, and clear labeling, especially for food and beverages. Post-pandemic, U.S. e-commerce exploded, raising the demand for secure, trackable packaging. The key players operating in the U.S. region has invested in large amount in research & development, with packaging companies collaborating with tech leaders in AI, IOT, and printed electronics.

Asia Pacific region is anticipated to grow at the fastest rate in the smart packaging market during the forecast period. Asia Pacific region is experiencing an e-commerce boom, especially in countries like China, India, Australia and Southeast Asia. Countries in Asia Pacific region are pushing for improved supply chain traceability, anti-counterfeiting, and environmentally sustainable packaging.

China’s policies on food safety tracking and pharmaceutical traceability has driven the growth of the smart packaging market. Japan, China, and South Korea are continuously putting efforts in launching smart labels, printed electronics, and AI-powered packaging.

In April 2025, According to Andrew Meyer, CEO of AeroFlexx, the company is in benefit by collaborating with spectrum to introduce new smart packaging solution, which will completely transform the pet grooming experience for pet owners as the packaging is spill-resistant and self-sealing. By using a lot less plastic without sacrificing durability, the AeroFlexx Pak not only offers convenience and ease of use but also supports environmental sustainability.

By Type

By Application

By Region

April 2025

April 2025

April 2025

April 2025