April 2025

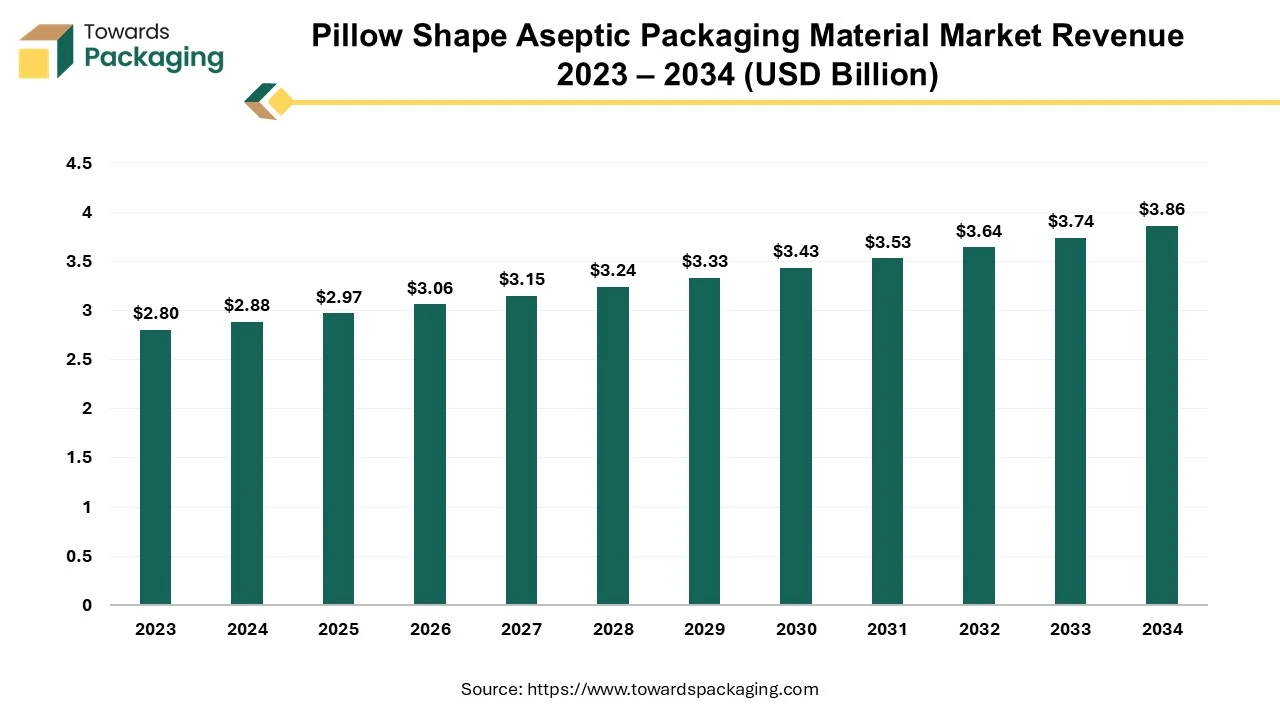

The global pillow shape aseptic packaging material market size reached USD 2.88 billion in 2024 and is projected to hit around USD 3.86 billion by 2034, expanding at a CAGR of 2.95% during the forecast period from 2025 to 2034.

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing pillow shape aseptic packaging materials which is estimated to drive the global pillow shape aseptic packaging material market over the forecast period.

Pillow shape aseptic packaging is type of flexible packaging used primarily for liquid food products. This packaging is designed in a pillow-like shape, typically consisting of a sealed pouch that protects its contents from contamination and preserves freshness. The product is sterilized separately from the packaging, ensuring a longer shelf life without refrigeration. The pillow shaped aseptic packaging is usually manufactured from multiple layers of plastic and aluminum foil, providing a barrier against light, air, and moisture. The pillow shape allows for efficient storage and transport, often being lightweight and easy to stack. This type of packaging is commonly used for juices, dairy products, and sauces, making it popular in both retail and food service industries.

Due to busy lifestyles, urbanization, and changing consumer preferences, there is rise in demand for the ready-to-eat food. With more people working long hours and balancing multiple responsibilities, convenience in meal preparation is essential. As urban population grows, access to cooking facilities may be limited, making ready-to-eat options more appealing. Many ready-to-eat options are marketed as healthy and nutritious, attracting health-conscious consumers.

Consumers increasingly seek variety and international flavours, which ready-to-eat products often provide. Increasing consumer preference for ready-to-eat and on-the-go food products boosts the need for convenient packaging. Increasing launch and sales of the ready-to-eat food products is estimated to drive the growth of the global pillow shape aseptic packaging material market over the forecast period.

Hence, due to the rise in the preference for the convince and ready-to-eat food there is constant increase in the demand pillow shape aseptic packaging material.

Sustainability Initiatives

Increasing focus on eco-friendly materials and recycling practices, leading to the development of biodegradable and compostable packaging options. Increasing focus on cost reduction and production efficiency can drive the specialty market growth further.

Smart Packaging

Developing smart packaging by integration of technology such as QR codes and sensors to enhance consumer engagement and provide real-time product information. Increasing in adoption of the advanced technology for the production of pillow shape aseptic packaging materials is estimated to drive the growth of the global pillow shape aseptic packaging material market in the near future.

Customization and Personalization

Growing demand for tailored packaging solutions to meet specific brand and consumer needs. Development of advanced materials that offer better barrier properties, enhancing the preservation of food products.

Innovations in packaging technology, such as enhanced barrier materials and intelligent packaging, can improve performance and attract new customers. The key players operating in the market are focused on adopting organic strategies like marketing for the aseptic packaging technology offered by the company, which has estimated to create lucrative opportunity for the growth of the pillow shape aseptic packaging material market over the forecast period.

The key players operating in the market are facing issue in adopting accurate technology for manufacturing pillow shape aseptic packaging material, which may restrict the growth of the pillow shape aseptic packaging material market over the forecast period. High production and raw material costs can limit adoption, especially among smaller manufacturers. Lack of awareness about the benefits of pillow shape aseptic packaging can limit market penetration.

The availability of alternative packaging solutions, such as traditional glass or plastic, may hinder market growth. Stricter regulations regarding food safety and packaging can pose challenges for manufacturers, requiring significant investment in compliance. Global supply chain issues can affect the availability of materials and increase costs. The specific use cases for pillow shape packaging may restrict market growth compared to more versatile packaging formats. Developing advanced materials that meet both performance and environmental standards can be challenging.

Asia Pacific region dominated the global pillow shape aseptic packaging material market in 2024. Rapid urbanization in countries like India, China, South Korea, Japan, etc. leads to changing lifestyles, with more consumers seeking convenient, ready-to-eat products that require effective aseptic packaging. Increased production and consumption of processed foods and beverages in Asia Pacific region drive the need for efficient packaging solutions.

Growing disposable income among consumers leads to increased spending on packaged foods, boosting demand for innovative packaging solutions. Rising health consciousness encourages the demand for products with longer shelf lives, which aseptic packaging can provide. Innovations in packaging technology improve the quality and functionality of aseptic packaging, making it more appealing to manufacturers.

North America region is anticipated to grow at the fastest rate in the pillow shape aseptic packaging material market during the forecast period. The North America region has a well-developed food and beverage sector that requires advanced packaging solutions to meet consumer demands for convenience and safety. North America is a hub for packaging technology advancements, leading to high-quality aseptic packaging options that improve product preservation and shelf life. There is a strong consumer preference for convenient, ready-to-eat products, which drives the demand for efficient packaging solutions like pillow shape aseptic packaging. The growth of online shopping trend in North America region increases the need for durable and efficient packaging solutions that can withstand shipping and handling.

The 100-250ml segment held a dominant presence in the global pillow shape aseptic packaging material market in 2024. The size range from 100-250ml is ideal for single-serve or on-the-go products, appealing to busy consumers seeking convenient packaging. The 100-250 ml packaging is suitable for a wide range of products, including beverages, sauces, and dairy items, making it popular among manufacturers.

The packaging from 100-250ml typically reduces material costs and can be more efficient for transportation and storage, appealing to manufacturers. As consumers increasingly seek portion-controlled products, this segment aligns well with health-conscious choices and reduced waste. The rise in demand for ready-to-drink beverages, such as juices and flavoured waters, boosts the popularity of this packaging size.

The compact design of 100-250 ml packages can enhance product visibility on shelves and attract consumers. These factors attribute to the dominance of the 100-250 ml segment in the market for pillow shape aseptic packaging materials.

The dairy segment registered its dominance over the global pillow aseptic packaging material market in 2024. Aseptic packaging allows dairy products to have a longer shelf life without the need for preservatives, appealing to both manufacturers and consumers. Aseptic packaging provides a barrier against light, oxygen, and contaminants, ensuring the quality and safety of dairy products.

As consumers increasingly seek ready-to-use dairy products, such as flavored milk and yogurt drinks, this type of packaging meets their needs effectively. Rising health consciousness drives demand for packaged dairy products, and aseptic packaging supports the preservation of nutrients and freshness.

The dairy sector is innovating with new flavours and formulations that require effective packaging solutions to maintain quality and safety. Many dairy brands are focusing on sustainable practices, and aseptic packaging can help reduce food waste and improve product lifecycle management.

“India, the biggest milk market in the world and one of the top juice-producing nations, will host SIG's first aseptic carton plant. The facility will be located in Gujarat's Ahmedabad.”

Furthermore, Vandana Tandan, SIG's Head of Markets for India and Bangladesh announced that the company will soon have locally made in India aseptic carton boxes. The company will be able to expand the selection of goods that Indian consumers can purchase with this factory. The SIG's Head of Markets for India and Bangladesh also announced that the company will provide long-lasting packaging, which comes in a variety of sizes to accommodate all consumption situations at reasonable price points, improves access to essential nutrients and prevents food waste.

By Type

By Application

By Region

April 2025

April 2025

April 2025

April 2025