April 2025

The molded paper pulp packaging market is on a strong growth trajectory, with revenue expected to surge by hundreds of millions between 2025 and 2034.

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing molded paper pulp packaging which is estimated to drive the global molded paper pulp packaging market over the forecast period.

Sustainable packaging material manufactured from recycled paper pulp that is shaped into a specific form through a molding process is known as molded paper. This process involves combining paper fibers, often derived from waste paper or other plant-based fibers, with water to create a slurry. The slurry is then poured into molds and pressed to form the desired shape. Once dried, the result is a rigid, durable, and biodegradable packaging material. The molded paper pulp packaging is eco-friendly in nature and can be customized. The molding process allows for the creation of custom shapes and sizes, making it suitable for various types of products, including food, consumer goods, electronics, and pharmaceuticals.

The molded paper pulp packaging is protective in nature and offers good protection for products during transport and handling, due to its cushioning properties, which help prevent damage from impact or vibration. The raw material (recycled paper) is generally inexpensive, and the production process can be relatively low-cost, making it a cost-effective packaging solution, especially for high-volume applications. Molded paper pulp packaging is commonly used for items such as egg cartons, electronic device packaging, and other fragile items that need protective and eco-friendly packaging.

As consumers become more environmentally aware, there is growing demand for sustainable packaging alternatives. Molded paper pulp is recyclable, biodegradable, and compostable, making it an attractive option for brands that want to align with eco-conscious values. This trend is particularly strong in industries like electronics, cosmetics, and food & beverage, where companies are seeking to reduce plastic waste and reduce their environmental footprint. As developing countries implement stricter environmental regulations, there is a growing focus on eco-friendly packaging solutions like molded paper pulp.

Brands are increasingly seeking customized packaging solutions that provide both aesthetic and functionality appeal. Molded paper pulp is highly customizable, which supports companies to develop packaging that aligns with their brand identity while also meeting the protective requirements of their products. Manufacturers are offering tailored designs with various colors, sizes, shapes, and finishes, allowing for more eye-catching and innovative packaging.

As the demand for smart packaging grows, manufacturers of molded paper pulp packaging are integrating technologies such as QR codes, RFID (Radio Frequency Identification), and NFC (Near Field Communication) into their products. These technologies help enhance product traceability, security, and consumer engagement. NFC and RFID can offer valuable information about the product's journey, rising transparency and trust with consumers.

Technological improvements in manufacturing processes are increasing the versatility and performance of molded paper pulp. Innovations in molding techniques, such as thermoforming, vacuum forming, and compression molding, supports for more intricate designs and better quality control.

The integration of Artificial Intelligence (AI) in the molded paper pulp packaging market has the ability to make exclusively improvements in different key areas, including sustainability, product design, manufacturing processes supply chain management. The AI integration can improve the manufacturing process if molded paper pulp packaging, making it faster, higher in quality and more cost-effective.

The AI helps in predicting predict when machinery is likely to require maintenance or break down, minimizing unplanned downtime and improving operational efficiency. This helps manufacturers avoid production delays and improve the reliability of their machinery. AI can enable the creation of smart packaging solutions that incorporate sensors or other technology into molded paper pulp products. For example, temperature-sensitive packaging for pharmaceuticals or food items could alert consumers or suppliers when the product has been exposed to unfavourable conditions during transport.

Environmental sustainability is a primary driver of the molded paper pulp packaging market. Consumers and industries alike are becoming increasingly aware of the detrimental effects of plastic waste, leading to a shift toward eco-friendly packaging alternatives. Molded paper pulp is biodegradable, recyclable, and compostable, making it a viable solution for businesses and consumers seeking sustainable packaging options.

Governments around the world are enforcing regulations to curb plastic usage. In 2018, the European Union announced plans to ban single-use plastics by 2021, and other countries are following suit with similar policies. These regulations push industries to find viable substitutes, and molded paper pulp packaging fits the bill as a sustainable alternative to plastic and Styrofoam.

As consumers become more environmentally conscious, there is an increasing demand for packaging that is eco-friendly and sustainable. This demand is particularly strong in industries such as food & beverage, electronics, and personal care, where environmentally responsible packaging is seen as a key differentiator for brands.

The key players operating in the market are facing issue in fulfilling the regulatory norms set by government as well as scarcity of raw material, which has observed to hamper the molded paper pulp packaging market over the forecast period. The availability of quality recycled paper and other fiber materials can be a challenge, particularly in areas with lower recycling rates. Fluctuations in raw material prices can also impact the production prices of molded paper pulp packaging. Some consumers still associate paper-based packaging with being less durable or less premium than plastic or glass. Educating consumers and businesses on the advantages of molded paper pulp is necessary for wider acceptance.

While molded paper pulp is an attractive option for many businesses, it faces competition from other sustainable packaging solutions, such as mushroom packaging biodegradable plastics, and bioplastics. These alternatives may offer benefits such as greater flexibility, higher strength, or improved aesthetics.

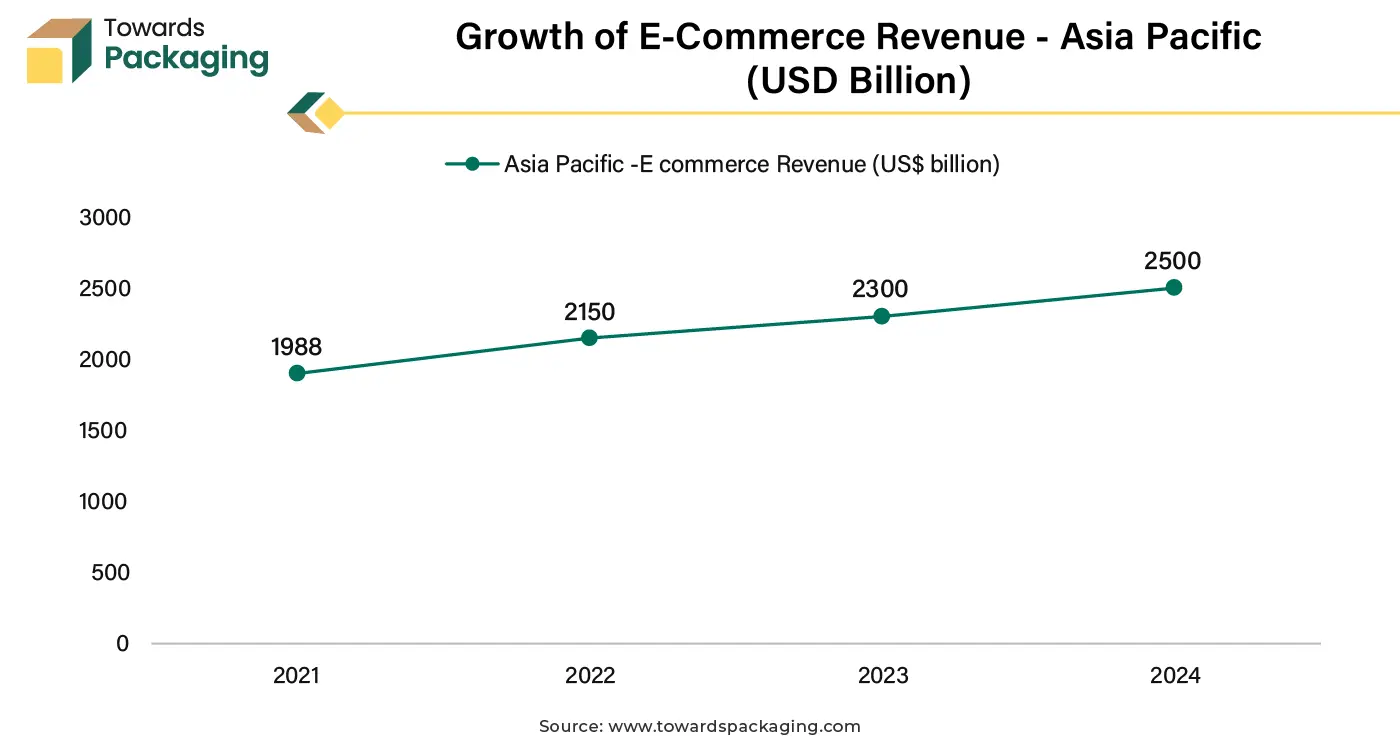

The growth of e-commerce, especially in the post-pandemic world, has created rise in demand for packaging solutions that can protect products during shipping while also being sustainable. Molded paper pulp is strong, lightweight, and has excellent cushioning properties, making it ideal for shipping products like fragile, electronics, and cosmetics items.

A significant component driving this surge is the tremendous rise in internet users. India has 954 million internet users as of March 2024, up significantly from 881 million in March 2023, according to the Telecom Regulatory Authority of India (TRAI).

China is predicted to have US$2.29 trillion in sales in 2024, making it the largest e-commerce industry in the world. E-commerce in the US is expected to grow to a value of US$1.1 trillion.

Unlock Infinite Advantages: Subscribe to Annual Membership

The wood pulp segment held a dominant presence in the molded paper pulp packaging market in 2024. Wood is a renewable resource, and trees are extensively available, making wood pulp a sustainable raw material for mass production. Managed forests and tree plantations ensure a steady supply. Wood pulp is relatively inexpensive to produce compared to other fibers or materials, which makes it an economically viable choice for large-scale packaging production. Paper pulp packaging is recyclable, which helps reduce environmental impact and supports the circular economy. Since wood pulp is biodegradable, it also breaks down naturally in the environment if it is not recycled. These factors attribute to make wood pulp an ideal material for the production of paper pulp packaging, balancing cost, strength, sustainability, and flexibility.

The non-wood pulp segment is expected to grow at the fastest rate in the molded paper pulp packaging market during the forecast period of 2024 to 2034. The non-wood pulp segment is expected to increase at the fastest rate throughout the course of the forecast period. The non-wood pulp market is expanding as a result of increased concerns about deforestation. This pulp is made from agricultural waste, including sugarcane, grasses, and cereal straws, as well as non-wood cellulosic plant material. This is becoming more and more popular in pulp production since it is readily available, less expensive, and there are growing concerns about deforestation.

The transfer molded segment led the global molded paper pulp packaging market. As the transfer molding allows for precise control over the shape of the pulp, which makes it highly suitable for developing custom-designed packaging solutions. This is especially valuable for packaging uniquely shaped products, like electronics or delicate glassware. Transfer-molded pulp is made from recycled paper or wood pulp, making it biodegradable and environmentally friendly. It can be recycled after use, contributing to a circular economy and reducing waste.

The natural, eco-friendly appearance of transfer-molded pulp also appeals to consumers and companies looking for sustainable, aesthetically pleasing packaging. As compared to other mold types such as thick wall, processed, compression molding, transfer molding generally provide faster cycle times due to its ability to inject the material into the mold under higher pressure.

The trays segment registered its dominance over the global molded paper pulp packaging market in 2024. Molded paper pulp trays provide excellent cushioning and support, making them ideal for protecting products during shipping and handling. They help absorb shocks, vibrations, and impacts, which is crucial for delicate or breakable items like electronics, glassware, and food packaging. It is widely used in food industry for packaging fruits, vegetables, and other food items.

Molded pulp trays are versatile and can be designed for an extensive range of products beyond food, including consumer electronics, cosmetics, and industrial parts. This makes molded pulp a go-to material for a broad range of industries. Overall, molded paper pulp trays offer a combination of strength, sustainability, cost-effectiveness, and versatility, which makes them a popular choice for packaging applications.

The food packaging segment dominated the molded paper pulp packaging market globally. Molded paper pulp is made from natural materials like recycled paper or wood pulp, which are non-toxic and safe for direct contact with food. Unlike certain plastics or foam materials, molded pulp doesn't contain harmful chemicals that could leach into food, making it a safe choice for food packaging. With growing concern about the environmental impact of plastic waste, molded paper pulp packaging is an attractive alternative because it is biodegradable, recyclable, and compostable.

Consumers and businesses are increasingly seeking sustainable packaging options, and molded pulp aligns well with these values, making it a preferred choice for eco-conscious brands. Increasing launch of paper-based food packaging has estimated to drive the segment growth over the forecast period.

The Asia Pacific region held a significant share of the molded paper pulp packaging market in 2024. Rapid industrialization and the rise of consumer demand for packaged goods in countries like China, India, and Japan are accelerating the adoption of sustainable packaging solutions. Although sustainability efforts in some regions are still catching up, there is increasing environmental awareness among consumers and companies, particularly in countries like Japan and South Korea.

As environmental concerns over plastic waste increase, many countries in the Asia-Pacific region are focusing on sustainable packaging solutions. Molded pulp packaging, being biodegradable and recyclable, fits well within the region's growing emphasis on reducing plastic pollution.

Asia Pacific is a major manufacturing hub for many global companies. As companies shift towards eco-friendly packaging, molded paper pulp is increasingly being adopted as a cost-effective, sustainable alternative to plastic and foam packaging. The presence of well-established pulp and paper industries in countries like China, India, and Indonesia has further facilitated the growth of molded paper pulp packaging.

North America is anticipated to grow at the fastest rate in the molded paper pulp packaging market during the forecast period. The booming e-commerce sector in North America is driving demand for protective and eco-friendly packaging. Molded paper pulp is an ideal solution for shipping fragile products, electronics, and cosmetics, which are commonly sold online. The booming e-commerce sector in North America is driving demand for protective and eco-friendly packaging. Molded paper pulp is an ideal solution for shipping fragile products, electronics, and cosmetics, which are commonly sold online.

Many large companies in North America (including tech giants and consumer goods brands) have committed to sustainability goals, further promoting the adoption of molded paper pulp packaging. These companies are increasingly focused on reducing their environmental footprint, which includes shifting toward recyclable and biodegradable packaging.

For the manufacturing of dry-molded fiber, PulPac introduces a new CoE. PulPac's plan to bring sustainable packaging solutions to the market more quickly includes this institution.

By Source

By Molded Type

By Product

By End Use

By Region

April 2025

April 2025

April 2025

April 2025