April 2025

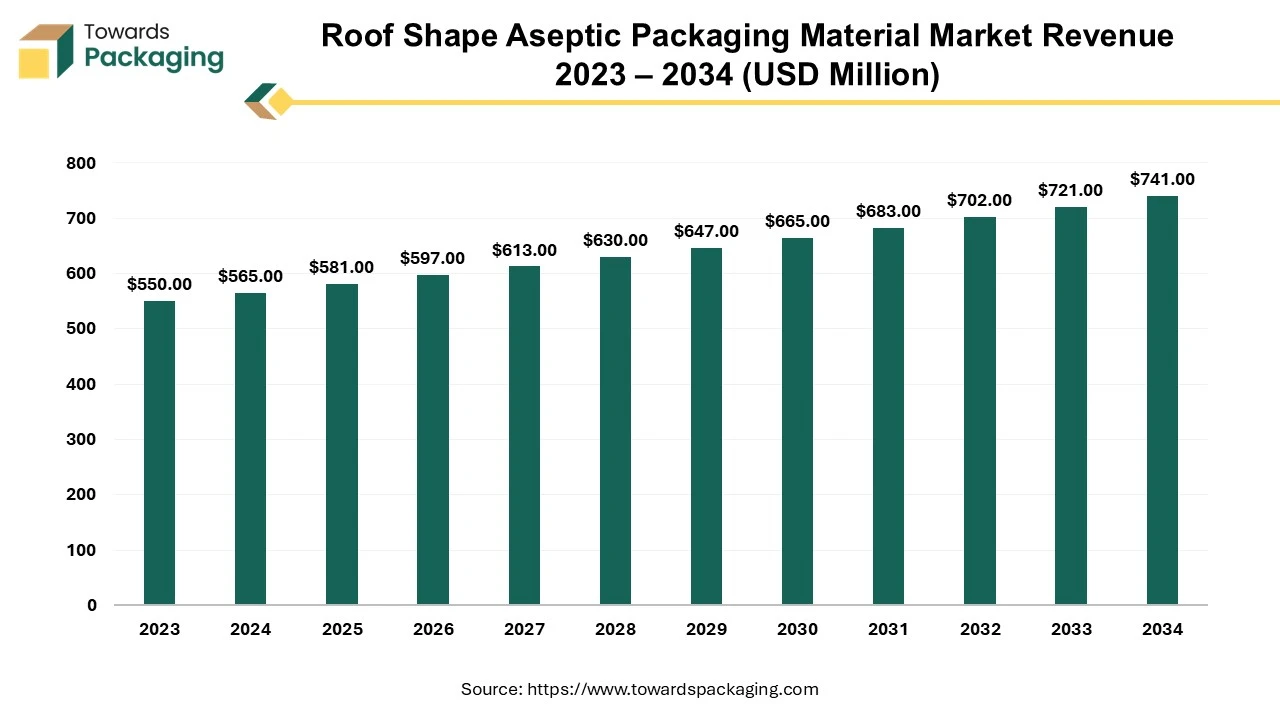

The global roof shape aseptic packaging material market size reached US$ 565 million in 2024 and is projected to hit around US$ 741 million by 2034, expanding at a CAGR of 2.75% during the forecast period from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing roof shape aseptic packaging material which is estimated to drive the global roof shape aseptic packaging material market over the forecast period.

The roof shape aseptic packaging material is majorly used for protection from contamination and extension of shelf life. Roof shape aseptic packaging is known for its specific design utilized primarily in the packaging of food and beverages that require long shelf life without refrigeration. This type of packaging ensures that products are protected from microbial contamination, extending their freshness and safety for consumers. The roof shape packaging is produced using an aseptic filling process. This involves sterilizing both the packaging material and the product separately, allowing for sterile conditions during filling. This prevents any contamination that could spoil the product.

The roof shape typically features a triangular or peaked top, which can enhance structural integrity and facilitate stacking and storage. This design is particularly effective in maximizing space efficiency during transportation and on retail shelves. Roof shape aseptic packaging is usually made from composite materials, including layers of paperboard, polyethylene, and aluminum foil. This multi-layer construction provides excellent barrier properties against light, moisture, and oxygen, crucial for preserving the quality of food and beverages. This type of packaging is suitable for an extensive variety of products, including dairy products (like milk and cream), juices, soups, sauces, and ready-to-eat meals. The roof shape design allows for various fill volumes, catering to different market needs.

Roof shape aseptic packaging is an innovative solution in the food and beverage industry, offering a combination of safety, quality, and convenience. Its design and functionality cater to the growing demand for long shelf-life products, making it an essential choice for manufacturers aiming to meet consumer needs while adhering to safety standards.

The ongoing growth of the food and beverage sector, particularly in emerging markets, is increasing the demand for effective and efficient packaging solutions. The key players operating in the food and beverages market are focused on raising funds for expanding the food and beverages sector, which has observed to raise the demand for the roof shape aseptic packaging material and driven the market growth.

For instance, in July 2024, Botrista, Inc., beverages and solutions providing company, raised the funding to boost the automated beverage platform growth. The developer of an automated, data-driven beverage platform, Botrista, has closed its Series C fundraising round, raising a total of US$120 million. This investment demonstrates Botrista's expanding market share in the restaurant sector and reflects the shifting need for creative and superior cold beverage menu alternatives around the world.

Hence, due to the expansion of the food & beverages industries the demand for the aseptic packaging material has risen, which is estimated to drive the growth of the global roof shape aseptic packaging material market in the near future.

Rising Focus on Sustainability: There's a growing emphasis on eco-friendly materials and practices, leading companies to adopt recyclable and biodegradable packaging solutions. Increasing in adoption of the advanced technology for the production of Roof Shape Aseptic Packaging Material is estimated to drive the growth of the global roof shape aseptic packaging Material market in the near future.

Regulatory Support: Favourable regulations regarding food safety and packaging are encouraging the use of aseptic solutions. The rising consumer preference for shelf-stable food and beverages, which require no refrigeration, is a significant driver for the global roof shape aseptic packaging material market over the forecast period. This trend is especially notable in developing regions where refrigeration infrastructure may be limited.

The rise in ready-to-eat meals and beverages is driving the demand for aseptic packaging, which extends shelf life without refrigeration. Brands and retailers are increasingly focusing on packaging that enhances product visibility and appeal, driving the adoption of aesthetically pleasing and functional designs like roof shape packaging. The key players operating in the market are focused on adopting the inorganic growth strategies like collaboration to develop roof shape aseptic packaging material, which is estimated to create lucrative opportunity for the growth of the global roof shape aseptic packaging material market over the forecast period.

The key players operating in the global roof shape aseptic packaging material market are facing issue due to high initial cost of production of aseptic material for packaging of beverages and food. The manufacturing processes for aseptic packaging materials can be expensive, which may limit adoption among smaller companies. The complexity of production and the need for specialized machinery can pose challenges, particularly for new entrants. Other packaging solutions, such as traditional cartons and plastic containers, may be preferred due to lower costs or greater availability.

Limited understanding of the benefits of aseptic packaging among consumers can hinder market growth. Stringent regulations regarding food safety and packaging materials can complicate market entry and expansion. In mature markets, growth potential may be limited due to already established competitors and market saturation. These factors may challenge the growth and adoption of roof shape aseptic packaging materials in certain segments.

Asia Pacific dominated the global roof shape aseptic packaging material market in 2024. The increasing urban population is driving demand for convenient food and beverage options, which boosts the need for aseptic packaging. Rising disposable incomes and changing lifestyles in countries like China and India lead to higher consumption of packaged foods. Improved logistics and supply chain infrastructure facilitate the distribution of products using aseptic packaging. The region is home to several leading packaging companies, enhancing competitive dynamics and fostering market growth. Asia Pacific being the largest market for dairy products and the food the demand for the aseptic packaging is high in the region.

Over 340 clients throughout 78 countries are served by the Lamipak company two manufacturing plants, which are situated in Kushan, China, and Indonesia. Leading, internationally renowned dairy and drink firms are among Lamipak clients. We sent 13 billion packages worldwide in 2023, and as Lamipak company add more clients, the Lamipak expect this sales volume to increase even further. Along with highlighting Lamipak's wide variety of aseptic packaging formats created especially for the Indian dairy market, Karunesh Singh, ISU Cluster leader for Lamipak, provides insight into developments that are expected to affect the Indian dairy business in 2024.

North America region is anticipated to grow at the fastest rate in the global roof shape aseptic packaging material market during the forecast period. The rise of online food delivery and e-commerce platforms in North America region has increased the demand for robust and safe packaging solutions to maintain product integrity during transportation. Increased consumer awareness regarding food safety and hygiene is driving demand for aseptic packaging, which ensures longer shelf life and reduces contamination risks. A growing preference for convenience foods and ready-to-drink beverages among busy consumers is boosting the adoption of aseptic packaging solutions. These factors contribute to a favourable market environment for roof shape aseptic packaging materials in North America.

The 100-250 ml segment held a dominant presence in the roof shaped aseptic packaging material market in 2024. The 100- 250ml volumes are often more convenient for consumers, allowing for single-serving sizes that reduce waste and encourage on-the-go consumption. This size range is versatile, suitable for various products like juices, dairy, and sauces, appealing to a wide range of manufacturers. Aseptic packaging is designed to extend shelf life without refrigeration, making these smaller volumes ideal for products that benefit from longer storage times. Increasing health-consciousness among consumers drives demand for smaller, portion-controlled products, fitting well within the 100-250 ml segment. These factors combined attribute to growth of the segment over the forecast period.

The dairy segment registered its dominance over the global roof shaped aseptic packaging material market in 2024. Roof shape aseptic packaging allows dairy products to have a longer shelf life without refrigeration, which is crucial for distribution and storage. This packaging method helps preserve the taste, texture, and nutritional value of dairy products, making them more appealing to consumers. Roof shape packaging is often lightweight and easy to handle, making it convenient for consumers to store and pour. Unique packaging shapes can enhance brand visibility and recognition on store shelves, attracting consumer attention.

By Type

By Application

By Region

April 2025

April 2025

April 2025

April 2025