April 2025

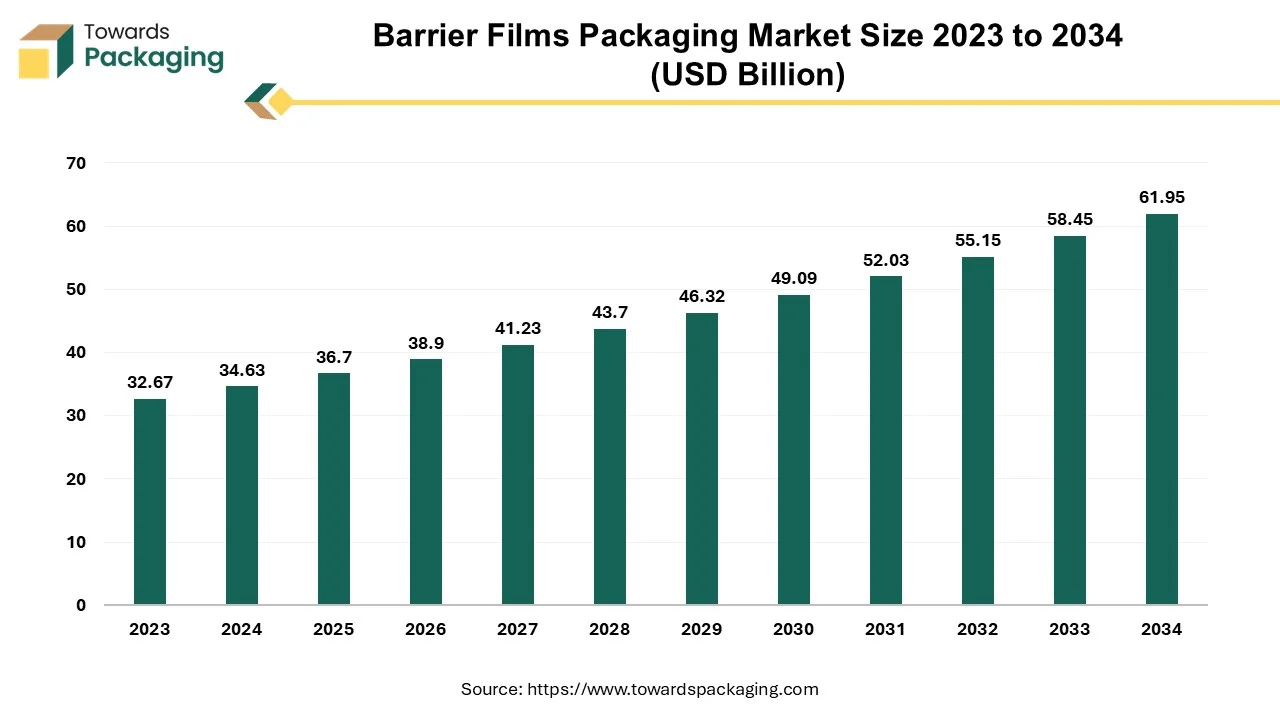

The barrier films packaging market is anticipated to grow from USD 36.7 billion in 2025 to USD 61.95 billion by 2034, with a compound annual growth rate (CAGR) of 5.99% during the forecast period from 2025 to 2034.

The capability of the barrier films to shield the goods from gases, moisture and light makes them a popular option for packing. The usage of film having barrier qualities is necessary for several reasons. One of the primary factors is to extend the product's shelf life by maintaining a proper ratio of the moisture and gas inside the container, which keeps the goods from going bad and shields it from the bacteria that could lead to the deterioration. Additionally, barrier coatings can decrease the cross-contamination of flavors as well as the transfer of light and odors. In addition to shielding the goods from temperature fluctuations, barrier films protect the packaging with alternatives that are impact and puncture-resistant. These films have a broad scope of applications like food, medications as well as electronics and are composed of various materials like nylon, polyethylene and polypropylene. Thus, the barrier film for packaging market is likely to grow at a significant CAGR during the forecast period.

The growing demand for packaged food coupled with the increasing need for films that can support in the extension of the shelf life of the products through guarding it from various external factors is anticipated to augment the growth of the barrier films for packaging market within the estimated timeframe. The increased awareness and regulatory pressures around sustainability along with the growth of the e-commerce sector are also expected to support the market growth in the near future. Furthermore, the increasing demand for customer-friendly packaging as well as the growing number of retail chains in developing economies is also expected to contribute to the growth of the market in the years to come.

Food can be kept fresher longer by postponing the deterioration that certain substances may cause to it. The main offenders are oxygen, temperature, light, and humidity. For instance, these substances result in microbial growths, enzymatic reactions, and vitamin destruction; hence, barrier packaging is essential to preserve the freshness of a variety of foods. Barrier packaging is becoming increasingly prevalent in the market, but for reasons other than its ability to preserve food. The most recent developments in this type of food packaging have also generated a lot of buzz within the overall sector.

Many studies are being conducted to find ways to reduce the amount of materials required to produce this type of packaging and thereby reduce the costs. Research on decreasing its weight is still under progress, as doing so would reduce the production costs and facilitate the storage as well as the transportation. Furthermore, a growing amount of recyclable barrier packaging is being created in an effort to provide a more sustainable substitute for the current packaging methods.

Food waste occurs for a variety of factors and it is not just an ethical but also a financial and ecological issue. Every year, Americans throw away 92 billion pounds of food, or 145 billion meals. Annually, they waste more than $473 billion worth of food. Surprisingly, 38% of the food produced in America is wasted. Furthermore, the Spanish Ministry of Agriculture reports that 7.7 million tonnes of the food is wasted annually in Spain. An estimated 40% of all the edible items winds up in the trash. The quality of the packaging is important in extending the shelf life of food, which is why researchers from several industries are researching on barrier packaging.

Dishes that have been prepared ahead of the time are extremely sensitive to oxygen. Foods can have their shelf lives extended by several weeks with the use of cold storage and barrier packaging methods that provide a modified or protective environment. Additionally, barrier materials prolong the crunchy texture of other products, like snacks. Certain other products, like meat, fish and dairy products, benefit from barrier packaging since it helps preserve their freshness as well as the organoleptic qualities.

Most of the barrier films consist of several layers made-up of various materials, which make recycling challenging and add to the environmental issues. Due to their special barrier qualities, multilayer plastic films are essential to the food packaging sector and each year two million tons of these films are utilized worldwide. In addition to giving the food items a longer shelf life, these films are frequently utilized earlier in the food value chain. Plastic film is also used in the agriculture sector for a variety of purposes, including weed management, moisture and water conservation and pest attraction and repellent. Due to the fabrication process inefficiencies, about 40% of the produced multilayer films are unusable and constitute a significant source of postindustrial waste. There aren't any commercially feasible methods available right now that could bring these materials back into use in the manufacturing.

Yet, the development of multilayer films has up to now only focused on their barrier efficiency, ignoring their potential for recycling. About 3 million tons of the multilayer film trash are burned or dumped in landfills worldwide each year as a result of a lack of recycling options that are both environmentally and economically viable. A commercially feasible recycling venture faces obstacles by the broad range of materials used for each layer, the wide variations in the processing characteristics of the polymers used for multilayer films, the absence of multilayer film detection systems and the failure of multilayer film collection systems. The lack of effective recycling solutions for barrier films restricts the range of sustainable packaging techniques available, which might potentially hinder the market growth if companies look for other solutions or come under more scrutiny for their environmental effects.

Need for sustainable packaging is rising as the attention shifts to carbon reduction and solving the issue of plastic waste. Worldwide recycling programs based on the single-material packaging are picking up steam. Numerous multinational corporations have set goals for the recycling of the plastic materials used in packaging and containers, and are introducing a range of products to help them reach these targets.

For Instance

The recyclable oxygen barrier material OxyStar, created by Placon, is utilized in the thermoformed polyethylene terephthalate packaging. Nuts, high-fat oils, and high-vitamin C meats as well as cheeses have all been found to benefit from OxyStar. Since OxyStarTM is categorized as recyclable, it can be added to the regular PET regrind stream, unlike most barrier materials, which are deemed unrecyclable. By binding oxygen atoms into the thermoformed PET sidewall, the oxygen shielding additive prolongs the freshness of the packaged product.

For packaging the nuts and crisps, TIPA introduced its latest 312MET barrier film, which is biodegradable both at home and in an industrial setting. Their high barrier ensures that nuts and crisps don't need an extra sealing layer to function properly. According to the company, its film will help minimize the total of 290,000 tonnes of waste from plastic packaging that WRAP estimates are produced in the UK annually.

These technological innovations have led to improvements in the performance and versatility of barrier films and are likely to create various opportunities for the growth of the barrier films packaging market in the years to come.

The pouches segment captured largest market share of 36.21% in 2024. In recent years, these simple-to-open and reseal pouches have grown to be very popular. Flexible pouches are a staple of the contemporary food and drink packaging applications. They can hold a wide range of foods and beverages, including the energy shots, kettle chips, truffles, crisps, wheat crackers, mixed nuts, candied fruit and nut butter, among others. Furthermore, another reason for the increasing popularity of these simple, low-cost, and flexible pouches is that they have minimal environmental impact. The bulkier, costly rigid packaging supplies are being rapidly pushed off the shelves at the supermarket by them. The fact that stand-up pouches have a substantially smaller environmental impact compared to the rigid packaging alternatives accounts for their surprisingly quick widespread adoption. Customers are also less likely to have wrap rage when using flexible pouches, which also take up a lot less place in landfills.

The food & beverages emerged as the largest segment in 2024 with market share of 64.81% on account of increasing demand for convenience foods with the changing consumer preferences. Furthermore, the increasing urbanization, rise in consumption of packaged food, increasing intake of canned vegetables & foods along with the improved standard of living are also expected to be the driving factors for the segmental growth of the market. The increasing consumer spending on the groceries mainly food and the demand for grocery on e-commerce platforms as well is also projected to remain high in the years to come which in turn is likely to contribute to the growth of the market segment.

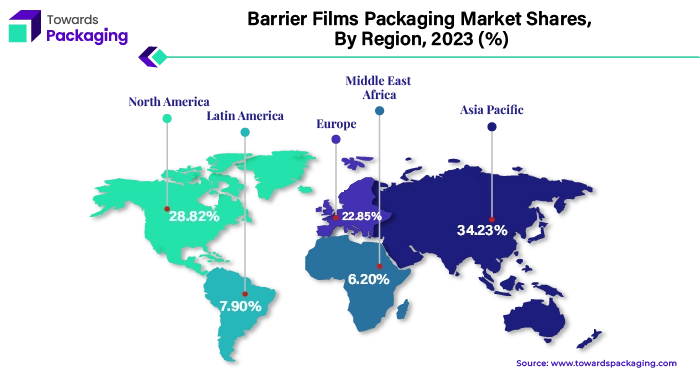

Asia Pacific held largest market share of 34.23% in 2024 and is expected to grow at a fastest CAGR of 7.73% during the forecast period. China is the largest market in the region. This is owing to the growing urban populations and busier lifestyles that have increased the demand for the convenient and long-lasting packaged foods across the region. Additionally, the growing modern retail formats and the exponential growth of the e-commerce sector in the economies like China, and India are also projected to contribute to the growth of the market in the region. Furthermore, the growing preference for premium and packaged food products with the increasing disposable incomes and escalating middle class population is also likely to support the regional growth of the market.

North America is expected to grow at a considerable CAGR of 5.36% in during the forecast period. This is due to the increasing the demand for convenient, ready-to-eat, and on-the-go food products across the region. Also, the stringent food safety regulations by the Food and Drug Administration (FDA) and other regulatory bodies are further expected to drive the demand for labels in the years to come. Furthermore, the growing focus on the sustainability and reducing the environmental impact of packaging along with the increasing demand from the pharmaceutical and healthcare sectors is also expected to support the regional growth of the market in the near future.

By Packaging Product

By Material

By Type

By End-user

By Region

April 2025

April 2025

April 2025

April 2025