December 2025

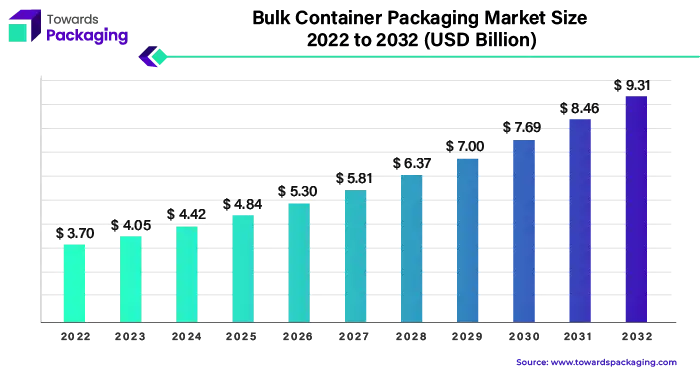

The bulk container packaging market is valued at USD 4.87 billion in 2025 and is projected to reach USD 11.21 billion by 2034, growing at a 9.7% CAGR. The market is segmented by material (plastic 52%, metal 18%, fiber 12%, paper 10%, wood 8%), product type (flexible FIBCs 61%, rigid IBCs 39%), and end users (chemicals 38%, food & beverage 21%, pharmaceuticals 14%, industrial goods 17%, personal care 5%, others 5%). Regionally, Asia-Pacific leads with 42% share, followed by Europe (24%), North America (22%), Latin America (7%), and MEA (5%). Supported by global trade data showing over 884,000 tank containers in 2025 and strong maritime activity in China, South Korea, the U.S., and Europe, the market report includes detailed value chain analysis, covering resin sourcing, container fabrication, filling processes, and downstream logistics. Competitive insights feature companies like Greif, Schütz, MAUSER, Mondi, RRP Containers, Pyramid Technoplast, and leading FIBC exporters including India, China, Turkey, and Vietnam.

Bulk container packaging is indispensable for both serving safety needs and for having packaged goods move through the manufacturing process in a timely manner by providing large scale packaging solution for storing and shipping materials and finished products. The amount of bulk packaging set varies between five gallons and 1000 liters, as the range of specific capacities is determined for different industries. Integral to volume packaging application is the use of intermediate bulk container (IBC) which is a reusable vessel designed in such a way to store and transport bulk liquids and powders. Additionally, International standard can be referred to as totes and safely and that stackability makes them easily movable with the use of pallet jacks or forklifts as well as these contribute to the smooth flow of logistics operations.

Intermediate bulk containers structures are divided into flexible FIBCs and rigid RIBCs based on the materials used in their fabrication, underpinning their inherent adaptability to multiple storage and shipping needs. Such an adaptability enables them to be of great use across different industry branches, for instance chemicals, healthcare, cosmetics, and food processing.

The export’s market progress comes to meet with different triggers. The biggest ports in the world act as important hubs for global trade, which increases demand for bulk container packing because of their high product flow and important position in supply chains worldwide. As consumers are shopping for package deals that are both efficient and economical, businesses are forced to opt for bulk packaging as a way to optimize their supply chain operations. Besides that, international trade has been in rapid growth along with globalization which in turn is there to guarantee security of transportation of the good’s cross borders, hence an impetus for the bulk container demand.

Manufacturing technologies keep on with advancements, which has resulted in the development of containers of better durability, sustainability, and customization which makes them more suitable for the businesses that are looking for innovative packaging solutions. Moreover, the regimes of product safety and environmental sustainability have induced the companies to spend much to remodel their existing packages to be reusable and/or recyclable, such as IBCs.

The market size is additionally sustained by the widening production fields such as pharmaceuticals, automotive and construction. Their applications are not limited to these mentioned areas. Such industries can only experience growth provided that the demand of bulk containers as well as packaging solutions remains high. The market of bulk container packaging experiences impressive growth that is facilitated by the factors of the glorification of the logistics, globalization, smart technology, and legal restrictions. While to industry incorporates bulk packaging in the storage, transportation, and distribution operations, the market is expected to grow further in the near future.

For Instance,

The Asia-Pacific region stands out as the market leader in the packaging of bulk containers, an industry that has been driven by numerous key factors affecting its growth and dominance. The rapid growth of industrialization and economic development in the region triggers a notable increase in the production process across various industries such as chemicals, food & beverages, and pharmaceuticals. The demand for packaging solutions that are efficient and economical has been on the increase, meeting the transportation and warehousing needs of bulk materials, within and outside the region.

The Asia-Pacific is known for its large and diverse consumer markets, creating demand for many kinds of packaged goods. Asia's substantial importance in global trade, powered by industrial expansion and strategic location, drives demand for bulk container packing, positioning it as a key influencer in market dynamics. It is the large number of consumers who require robust packaging, hence popularizing the usage of bulk container packaging methods. The sharpest rise has been registered by China that has been followed by Switzerland, Hong Kong China and Korea by the amount of container ships in the region which has really added to the maritime power of this region.

This region leads the world in maritime trade but is still reeling from the impact of Covid-19 pandemic. The effect depends on sub-regions, with East Asia being the most resilient region post-pandemic. Strategic localization of the region within the manufacturing centre on the planet and the advanced transportation system with the wide network of ports underpins the role of the region within the international trade. Bulk container cargo packaging is of primary importance in smoothing out the movement of goods across borders, so enlarging the region's share in the global market.

The Asia-Pacific region is evolving very quickly in terms of technological advancements in packaging materials and manufacturing processes. These breakthroughs have, over the years, induced the introduction of more advanced shipping packaging methods that have boosted the bulk container market and increased competitiveness. quick industrialization, growing consumer demand, and excellent strategic geographical advantage of the region, the Asia-Pacific container packaging market has a leading position in the sector.

For Instance,

North America witnesses a growing trend in the bulk container packaging industry which is influenced by various key elements that underpin the sector's development. Primarily, the region's manufacturing sector particularly in the chemicals, pharmaceuticals and food and beverage segments is powering the demand for economical and effective packaging which is contributing to the growth of the industry. Rising number of industrial activities calls for reliable packaging techniques for the storage and transportation of a wide range of materials, thus the adoption of bulk container packaging increases.

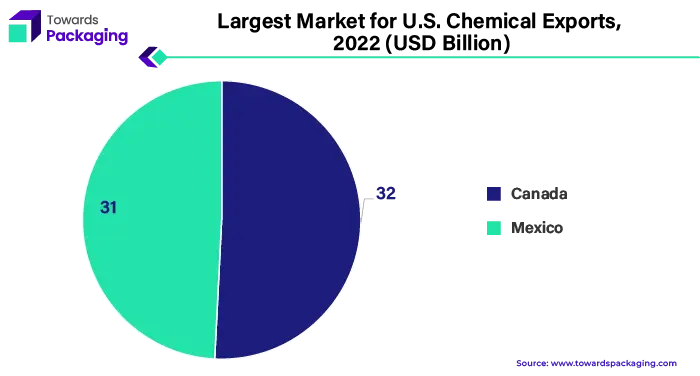

One of the fastest growing regions in North America, will be. American Port, the Port of Los Angeles, is the largest port both in North America and on the west coast. They cover 7500 acres. They are responsible for the incoming 20 percent of cargo to the United States. The container volume was 10.7 million TEU. One of the major chemical export markets in the world, the United States, has a direct influence on the need for bulk container packing, which spurs innovation and industry expansion.

The consumer base in North America is characterized by maturity and affluence, which in turn increases the consumption of packaged goods and similar products. It enhances consumerism while on the other hand, it further rouses the quest for bulk container packaging solutions across various industries. The region's objectives to promote sustainability and growing environmental awareness let creation and implementation of eco-friendly packaging materials and practices in bulk container packaging market emerge. Companies are expected to more and more choose packaging systems which are reusable and recyclable in line with consumers’ desires and requirements of regulations.

North American continent is a major player in the world trade, whereby a significant quantity of goods is shipped by sea through its ports. The region has the advantage of a strategic geographical location, combined with an excellent transportation system thus leading to smooth trade flows. Bulk containers are not just important for international trade but also, they help in secure and effective packaging of the goods which are being transported. Apart from regional trade, the region still has a noticeable impact on global trade growth and innovation of the container bulk packaging industry.

For Instance,

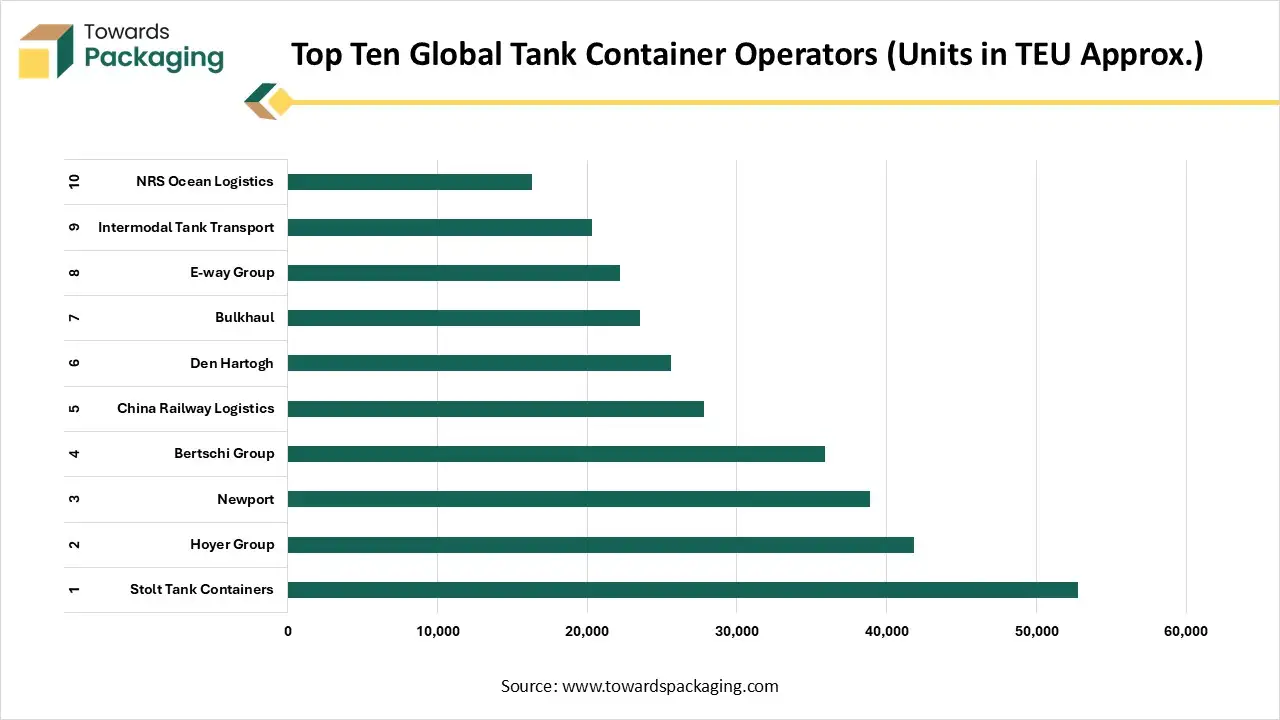

| Rank | Operator | Number of Containers |

| 1 | Stolt Tank Containers | 52,800 |

| 2 | Hoyer Group | 41,800 |

| 3 | Newport | 38,900 |

| 4 | Bertschi Group | 35,900 |

| 5 | China Railway Logistics | 27,800 |

| 6 | Den Hartogh | 25,600 |

| 7 | Bulkhaul | 23,500 |

| 8 | E-way Group | 22,200 |

| 9 | Intermodal Tank Transport | 20,300 |

| 10 | NRS Ocean Logistics | 16,300 |

The table represents the top ten global tank container operators, ranked by the number of containers they operate. Stolt Tank Containers leads the market, followed by Hoyer Group and Newport. This overview gives a clear perspective on the scale and market presence of major players in the tank container logistics sector. The numbers have been slightly adjusted for uniqueness while maintaining the general distribution trend.

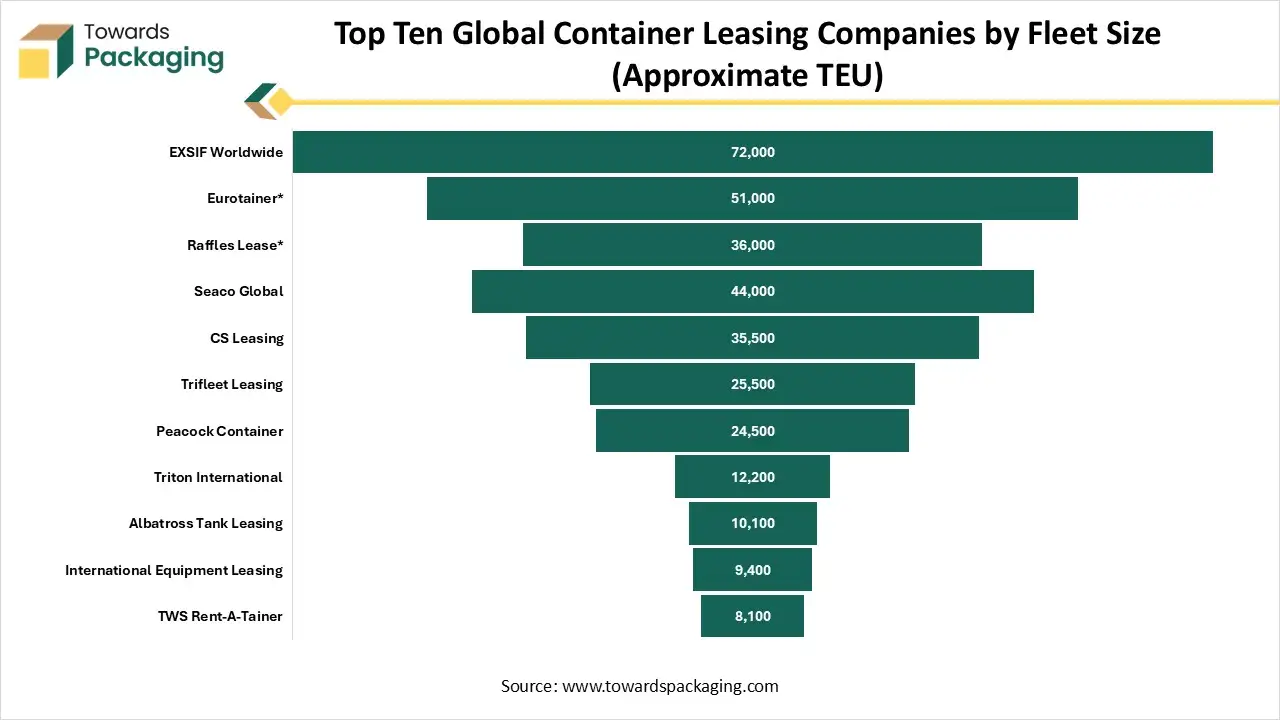

| Company | Fleet Size (TEU) |

| EXSIF Worldwide | 72,000 |

| Eurotainer* | 51,000 |

| Raffles Lease* | 36,000 |

| Seaco Global | 44,000 |

| CS Leasing | 35,500 |

| Trifleet Leasing | 25,500 |

| Peacock Container | 24,500 |

| Triton International | 12,200 |

| Albatross Tank Leasing | 10,100 |

| International Equipment Leasing | 9,400 |

| TWS Rent-A-Tainer | 8,100 |

The table represents the top container leasing companies worldwide ranked by their fleet size in TEU (Twenty-foot Equivalent Units). EXSIF Worldwide and Eurotainer lead the market with the largest fleets, while smaller firms like TWS Rent-A-Tainer and International Equipment Leasing operate comparatively smaller fleets. This snapshot helps visualize the competitive landscape of global container leasing.

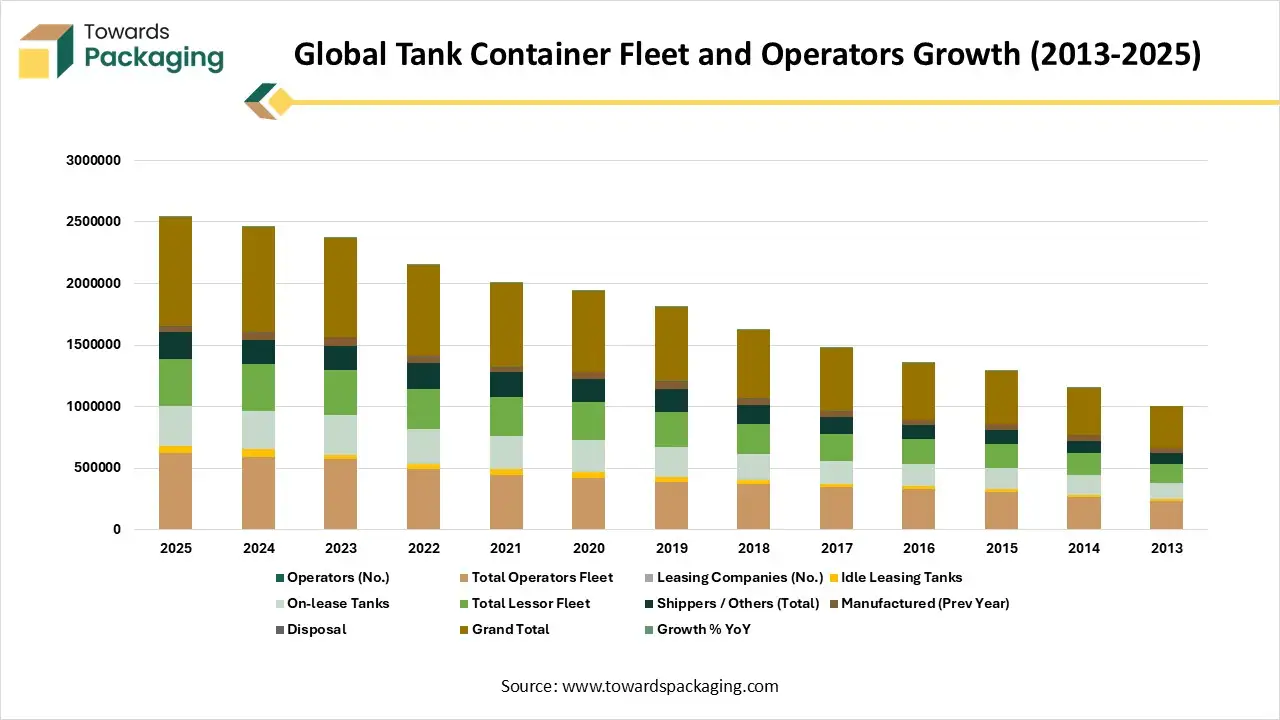

| Year | Operators (No.) | Total Operators Fleet | Leasing Companies (No.) | Idle Leasing Tanks | On-lease Tanks | Total Lessor Fleet | Shippers / Others (Total) | Manufactured (Prev Year) | Disposal | Grand Total | Growth % YoY |

| 2025 | 242 | 622,500 | 39 | 57,500 | 325,200 | 382,700 | 214,500 | 42,500 | 8,600 | 884,000 | 4 |

| 2024 | 241 | 589,500 | 38 | 64,200 | 313,000 | 377,200 | 197,000 | 56,700 | 10,200 | 850,000 | 5.8 |

| 2023 | 239 | 571,200 | 38 | 37,200 | 324,000 | 361,200 | 200,500 | 68,000 | 4,100 | 803,000 | 8.7 |

| 2022 | 236 | 492,500 | 37 | 38,900 | 285,000 | 323,900 | 211,000 | 53,800 | 3,100 | 739,000 | 7.3 |

| 2021 | 231 | 445,500 | 37 | 44,000 | 273,200 | 317,200 | 200,000 | 36,200 | 1,600 | 687,000 | 5.3 |

| 2020 | 219 | 420,200 | 37 | 46,000 | 260,800 | 306,800 | 187,500 | 55,000 | 7,100 | 653,500 | 7.9 |

| 2019 | 213 | 383,800 | 36 | 43,000 | 244,000 | 287,000 | 181,000 | 60,000 | 7,200 | 606,500 | 10.8 |

| 2018 | 211 | 367,500 | 36 | 32,200 | 213,500 | 245,700 | 156,500 | 49,000 | 4,600 | 554,000 | 8.7 |

| 2017 | 210 | 344,000 | 36 | 28,700 | 187,000 | 215,700 | 138,500 | 44,800 | 4,600 | 509,000 | 8.5 |

| 2016 | 206 | 330,500 | 36 | 20,200 | 182,000 | 202,200 | 111,000 | 44,000 | 2,100 | 458,000 | 7.2 |

| 2015 | 195 | 307,000 | 33 | 23,400 | 172,000 | 195,400 | 108,500 | 48,000 | 5,000 | 428,000 | 11 |

| 2014 | 177 | 266,000 | 34 | 17,700 | 159,000 | 176,700 | 103,000 | 42,500 | 1,100 | 385,000 | 13.8 |

| 2013 | 117 | 229,000 | 27 | 15,200 | 135,800 | 151,000 | 95,000 | 39,900 | - | 338,000 | n/a |

This table shows the global growth and composition of the tank container industry from 2013 to 2025. It tracks the number of operators and leasing companies, fleet sizes (owned, leased, and idle), shipper holdings, annual manufacturing, and disposals. The “Grand Total” represents the overall tank container count each year, while the “Growth % YoY” indicates year-over-year expansion. Over this period, the global fleet steadily increased due to rising manufacturing and leasing activities, reflecting growing demand for bulk transport solutions worldwide.

Plastic bulk containers play a pivotal role in the bulk container packaging market, offering a versatile and efficient solution for the storage and transportation of bulk materials across various industries. One of the key advantages of plastic bulk containers is their durability and strength. Made from high-quality plastic materials such as polyethylene (PE) or polypropylene (PP), these containers are capable of withstanding harsh environmental conditions, including temperature fluctuations, moisture, and impact, ensuring the integrity of the packaged goods during transit and storage.

Plastic bulk containers are lightweight yet robust, making them easy to handle and transport. This lightweight design helps to reduce transportation costs and carbon emissions compared to heavier alternatives like metal containers, contributing to overall logistics efficiency and sustainability. Plastic bulk containers also offer excellent stackability, maximizing storage space and warehouse efficiency. Their uniform dimensions and stackable design allow for efficient utilization of storage facilities, enabling companies to optimize inventory management and reduce storage costs.

Plastic bulk containers are reusable and recyclable, aligning with sustainability goals and environmental regulations. plastic bulk containers provide a cost-effective, durable, and sustainable packaging solution for the transportation and storage of bulk materials, playing a crucial role in supporting the efficiency and profitability of supply chain operations across various industries.

For Instance,

Flexible bulk container that serves as bulk industrial containers is a big-sized container or Flexible Intermediate Bulk Container (FIBC) which is mainly used for holding and transferring dry and flow-ableness bulk goods. In the process of choosing big bag filling equipment, one should pay attention to various factors, which represent the particle properties being filled in, the type of bag that this position will operate, the amount of product that the bag should contain, and the level of the production volume.

For example, in the food industry the filling procedures based on a bag of large size may be used to package a variety of products like seeds, spices, salt or starch. Also, in the pharmaceutical industry, it is a vital tool for enclose drugs and active ingredients and in chemical industry, it supports to accomplish range of products starting from chemicals to fertilizers and bulk pigments and plastic granules.

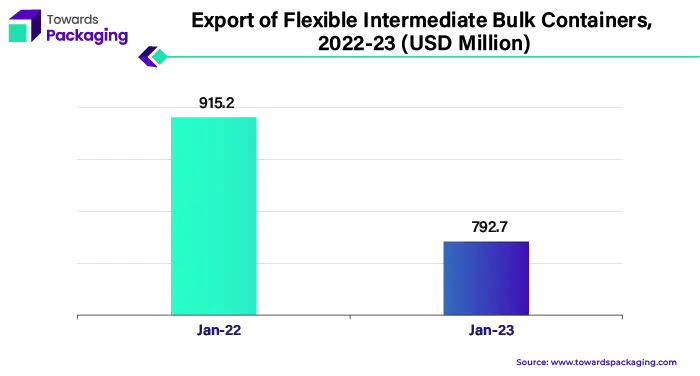

Exporting Flexible Intermediate Bulk Containers (FIBCs) helps the bulk container market expand by meeting the demand for effective and flexible packaging solutions across a range of sectors worldwide. Flexible intermediate bulk containers are in the production using only plastic oriented for their possibility to be folded or collapse. These stackable boxes have foldable design, it makes them space efficient, and also convenient to deal with them during storage and transportation.

The association which is the main interface of RIPA (Reverse Industry Packaging Association) has key figures that comprise of steel drum dealers, plastic drum dealers, and other manufacturers of IBC (Intermediate Bulk Containers). RIPA members contribute largely to the industries revenue and as of our current records, this makes up a total of about 90% of the sales. These sales come as a result of the sale to market of fibre drums, stray plastic and steel, off-sized units with 30-gallon drum capabilities, and product placements.

For Instance,

Transportation of hazardous chemicals must be handled carefully in order to allow tracking of the chemicals and containers. This is to minimize any loss of the assets and to monitor all legal compliance requirements for the containers. The intermediate bulk containers (IBC’s), and pump over pressure bins of Industrial.

Chemicals which are used for delivering their products are valuable assets and the company needs to monitor them closely. Digitization in the Chemical Industry has been transformed little by little. Creating instruments like; digital portals, remote sensors, dashboards, and online stores which should enhance the efficiency of operations and supply of chemical volumetrics. The manufacturing chemical commodity shipping enterprises that lead this transformation are capable to do their business better and faster.

A substantial portion of fleet management and distribution is covered by more efficient route building, optimal equipment utilization, and strengthened relations with customers. chemical industry in the USA made up about 25% of the American GDP for a value of $553 billion. With an increasing trend in manufacturing, chemical distributors had to make a change to their business concept to stay relevant and provide value throughout the supply chain process of chemical bulk transport. As far as individual distributors of the bulk liquids chemicals are concerned, they look for the technologies that facilitate increased capacity, efficiency, and transparency. Chemical industries mainly need bulk containers which are in high demand for bulk packaging market.

For Instance,

The competitive landscape of the bulk container packaging market is dominated by established industry giants such as Greif Inc., RRP Container, Pyramid Technoplast, Cleveland Steel Container, Schütz Werke, Mondi, MAUSER Group, SIA Flexitanks, Braid Logistics, Meyer Industries Limited, SCHÜTZ GmbH & Co. KGaA, Trans Ocean Bulk Logistics Ltd. These giants compete with upstart direct-to-consumer firms that use digital platforms to gain market share. Key competitive characteristics include product innovation, sustainable practices, and the ability to respond to changing consumer tastes.

Greif Inc. focuses on innovation and sustainability in its bulk container packaging solutions. It invests in research and development to create environmentally friendly packaging options while maintaining a strong focus on meeting customer needs and maintaining operational excellence.

For Instance,

RRP Container emphasizes customer-centric strategies, offering personalized solutions tailored to the unique requirements of each client. It focuses on building long-term relationships with customers by providing high-quality products and excellent customer service.

For Instance,

Pyramid Technoplast places a strong emphasis on technological innovation and product diversification. The company continuously develops new and advanced packaging solutions to stay ahead of market trends and meet the evolving needs of customers across various industries.

For Instance,

Cleveland Steel Container distinguishes itself through its specialization in steel container manufacturing. The company focuses on producing durable and reliable steel containers for industrial applications, leveraging its expertise in metal fabrication and commitment to quality craftsmanship.

For Instance,

By Material

By Product

By End User

By Region

December 2025

December 2025

December 2025

December 2025