April 2025

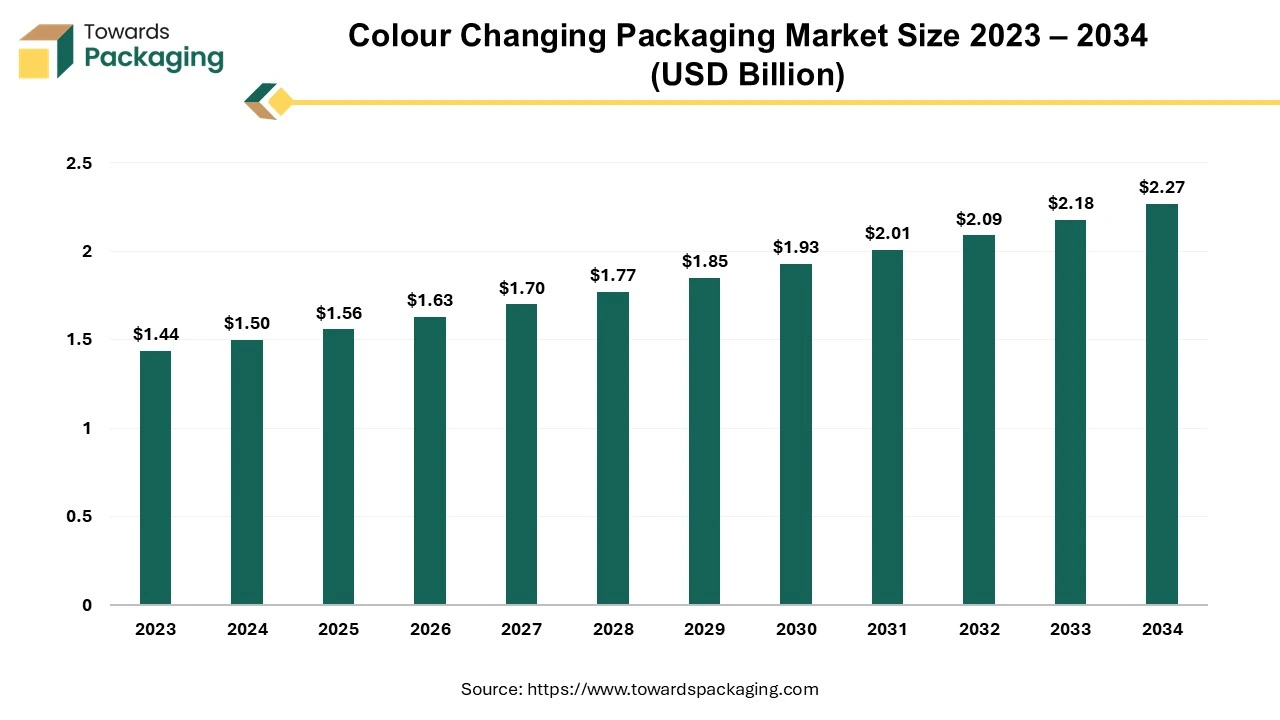

The global colour changing packaging market size was at US$ 1.50 billion in 2024 and is projected to touch US$ 2.27 billion by 2034, expanding at a CAGR of 4.25% during the forecast period from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing colour changing packaging which is estimated to drive the global colour changing packaging market over the forecast period.

Color-changing packaging is known as packaging materials that can change their color in response to specific stimuli, such as changes in light, temperature, pH, or other environmental factors. This technology is often utilized to enhance functionality, enhances user experience, or provide visual cues for consumers.

Common Types of Stimuli for Color-Changing Packaging are Thermochromic Packaging, Photochromic Packaging, pH-Sensitive Packaging, Gas-Sensitive Packaging and Time-Temperature Indicators (TTIs). The thermochromic packaging changes color with temperature variations. The photochromic packaging reacts to changes in light intensity or UV exposure.

Packaging that changes color with temperature variations is gaining popularity, especially in the food and beverage industry, to indicate optimal consumption temperatures. Advancements in photochromic materials, which react to light exposure, are being integrated into packaging to enhance user experience and brand engagement.

There's growing emphasis on developing biodegradable and recyclable color-changing packaging materials to meet environmental concerns. Interactive Consumer Experience: Brands are leveraging color-changing packaging to create interactive and engaging consumer experiences, enhancing brand loyalty and product appeal. These trends indicate a dynamic future for the color-changing packaging market, with technological advancements and consumer preferences driving innovation across various industries.

AI integration can notably improve the color-changing packaging industry by optimizing production processes, enhancing functionality, and developing personalized consumer experiences. AI-powered sensors and cameras can detect inconsistencies or defects in the color-changing features during manufacturing. Machine learning models can predict equipment failures or issues, minimizing downtime and ensuring consistent production quality.

AI can analyze data on different stimuli-responsive materials to recommend the most effective and cost-efficient options for specific applications. Algorithms can generate unique and adaptive color patterns tailored to consumer preferences or branding strategies. AI can integrate with AR/VR technology to develop interactive packaging that changes colors in response to user actions, such as scanning with a smartphone. AI systems can enable packaging to adapt its color-changing properties based on consumer profiles, preferences, or environmental factors.

In e-commerce, packaging that changes color to indicate tampering or environmental changes enhances trust in online purchases. The usage of colour changing packaging creates branding opportunities. Unique packaging adds an element of surprise and delight for online shoppers. During shipping, perishable goods like pharmaceuticals and food are vulnerable to temperature fluctuations. Color-changing packaging with thermochromic or freshness indicators can reassure consumers that products are delivered in optimal condition. Packaging that changes color to indicate tampering boosts consumer trust in the safety of products bought online.

Packaging that indicates exposure to heat, cold, or other environmental factors during transit helps eCommerce companies ensure quality delivery, especially for temperature-sensitive goods. Packaging that visibly indicates product status upon receipt simplifies return processes by providing visual proof of potential issues.

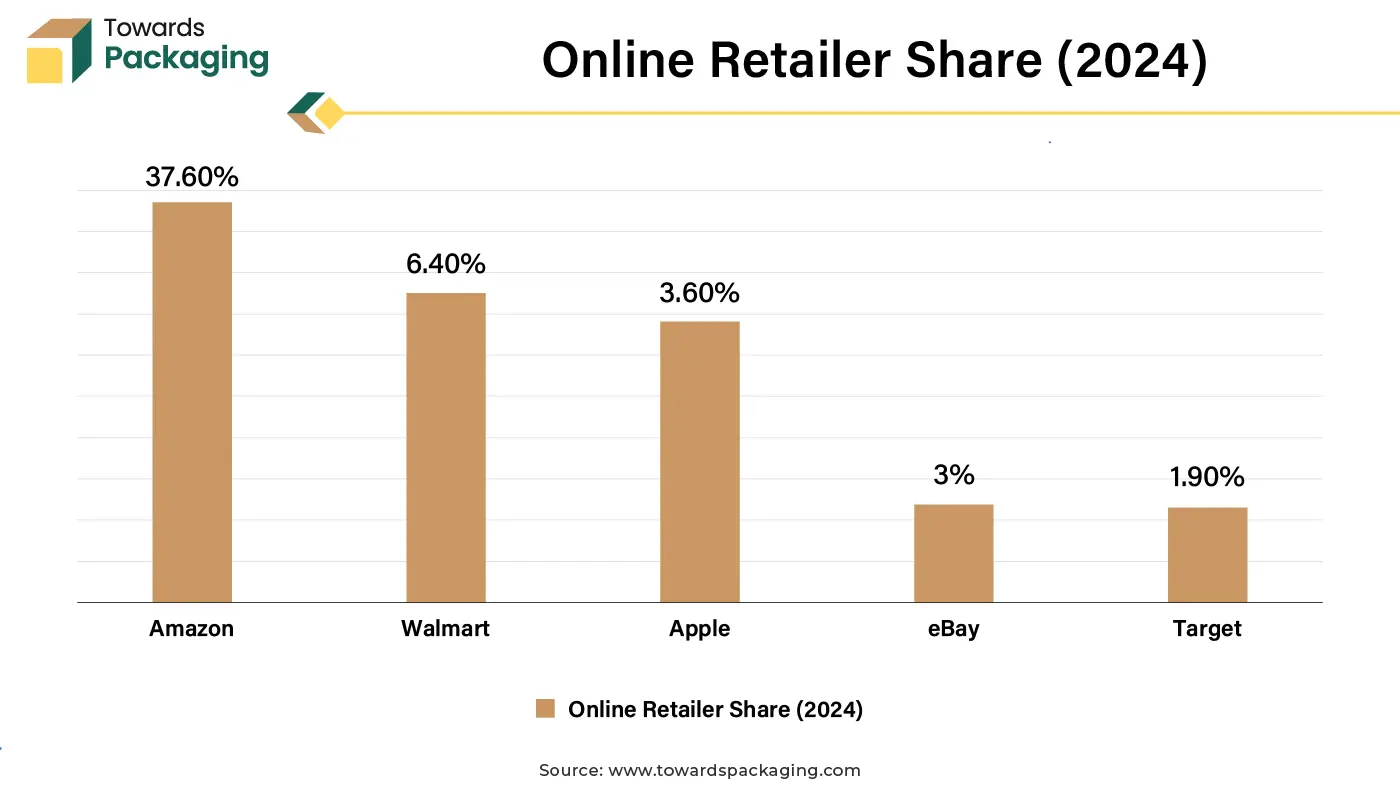

With more than five billion internet users globally, internet availability and adoption are growing quickly, and more and more individuals are making transactions online. Global retail e-commerce sales are predicted to surpass 4.1 trillion dollars in 2024, and this amount is anticipated to rise to unprecedented levels in the years to come.

The key players operating in the colour changing packaging market are facing scalability issues & competition from conventional packaging, which may restrict the growth of the market over the forecast period. The manufacturing processes for color-changing packaging are often complex and not easily scalable for mass production. Limited availability of specialized raw materials can hinder large-scale deployment.

Traditional packaging remains more affordable, especially for cost-sensitive markets like developing regions. The widespread availability and familiarity of conventional packaging solutions make them a more practical choice for many businesses.

Meeting food safety and environmental standards for new packaging technologies can be expensive and time-consuming. Different countries have varying regulations for packaging materials, which can restrict global adoption.

Thermochromic packaging, which changes color to indicate the optimal serving temperature, is becoming increasingly popular for beverages and frozen foods. Packaging that visually indicates the shelf life of food products helps reduce waste and ensures safety.

Development of advanced stimuli-responsive materials, such as thermochromic, photochromic, and gas-sensitive materials, enhances packaging functionality. Integration with smart technology combining color-changing packaging with digital tools, such as QR codes or IoT, adds value and develops interactive experiences.

The plastic segment held a dominant presence in the colour changing packaging market in 2024. Plastic easily accommodates color-changing additives like thermochromic and photochromic pigments during the manufacturing process. The structure of plastics allows for effective and reliable reactions to stimuli like temperature, light, or gas exposure. Plastic’s lightweight nature makes it easier to transport, reducing logistics costs. It is highly durable, ensuring that the color-changing properties remain intact during shipping and handling.

The thermal sensitivity segment accounted for a considerable share of the colour changing packaging market in 2024. The thermal sensitivity technology leverages materials that react to temperature changes to provide functional and visually appealing features in packaging. The thermal sensitivity technology ensures the quality and safety of temperature-sensitive products like beverages, food and healthcare products. It provides an interactive experience, improving brand differentiation. By indicating spoilage or improper storage, it helps reduce waste due to undetected damage.

The food & beverages segment to registered its dominance over the global colour changing packaging market in 2024. The color-changing packaging engages consumers by offering a novel and interactive experience. It adds aesthetic value and makes products stand out on store shelves, increasing their attractiveness to consumers. Some packaging changes color to indicate whether a product is at the right temperature for consumption (e.g., chilled beverages). Color changes can also signal the freshness of food, helping consumers avoid spoiled products. Color-changing packaging helps brands differentiate themselves in a competitive market. This combination of aesthetically appealing, practicality, and consumer engagement attributes to drive the high requirement for color-changing packaging in the food and beverage industry.

The pharmaceutical segment is expected to grow at the fastest rate in the colour changing packaging market during the forecast period of 2024 to 2034. Many pharmaceuticals are temperature-sensitive. Color-changing packaging can indicate if a product has been stored or transported outside its required temperature range, ensuring safety and efficacy. Color changes can alert consumers to tampering, enhancing product security and regulatory compliance. Color-changing labels or caps can remind patients to take their medications at the right time, improving adherence to treatment regimens.

The colour changing packaging helps in child safety by interactive and engaging designs help communicate important usage instructions to caregivers and improve safety for children. Color indicators can assist patients in understanding when a medication is ready for use (e.g., reconstituted powders). Integration with sensors and other smart technologies enhances the functionality of color-changing packaging, making it highly desirable for advanced pharmaceutical products. With sustainability being a growing focus, the industry supports innovation in color-changing materials that are environmentally friendly.

North America region held the largest share of the colour changing market in 2024. North America is a leader in technological innovation, fostering the development of advanced materials like thermochromic and photochromic inks used in color-changing packaging. The rise of connected devices in the region supports the adoption of smart packaging solutions that combine visual cues with data tracking. Consumers in North America are highly aware of food safety and quality issues, driving demand for packaging that provides visual indicators of freshness or spoilage. Growing environmental awareness encourages the adoption of sustainable and intelligent packaging solutions.

North America region’s well-established pharmaceutical industry requires temperature-sensitive packaging, especially for biologics, vaccines, and other high-value drugs. Stringent regulations for drug safety in North America further drive the adoption of color-changing solutions.

Regulatory bodies such as the FDA encourage the use of packaging technologies that enhance safety and compliance. North America is home to leading packaging manufacturers and technology providers, which accelerates the adoption of cutting-edge packaging solutions.

The FDA regulates materials that come into direct contact with food. This includes color-changing inks and coatings used in packaging. Ensuring compliance with these guidelines promotes trust in the safety of such technologies. The FDA requires pharmaceutical packaging to comply with Good Manufacturing Practices (GMP) and ensure product safety. Color-changing technologies that indicate temperature abuse or tampering align with these guidelines. For meat, poultry, and dairy products, the USDA mandates strict temperature controls.

Color-changing packaging that highlights spoilage or improper storage meets these requirements and enhances compliance. In Canada, packaging must include information in both English and French. Color-changing indicators that convey universal visual cues support compliance with bilingual packaging laws.

Asia Pacific region is anticipated to grow at the fastest rate in the colour changing packaging market during the forecast period. Asia-Pacific is a major hub for pharmaceutical manufacturing and distribution, especially for biologics, vaccines, and temperature-sensitive drugs. Color-changing packaging helps maintain the integrity of these products during transportation and storage. Governments in countries like India and China are enforcing stricter regulations on drug safety, promoting the use of advanced packaging technologies.

Asia-Pacific is home to some of the world’s largest packaging manufacturers, offering cost-efficient production of color-changing packaging materials. Many countries in the region produce packaging solutions for export, driving economies of scale and technological advancement. Consumers and regulators in the region are increasingly focused on sustainability, encouraging the development of recyclable and biodegradable color-changing packaging materials. The use of packaging that indicates spoilage helps address the issue of food waste, which is a growing concern in Asia-Pacific.

By Material

By Technology

By End Use

By Region

April 2025

April 2025

April 2025

April 2025