April 2025

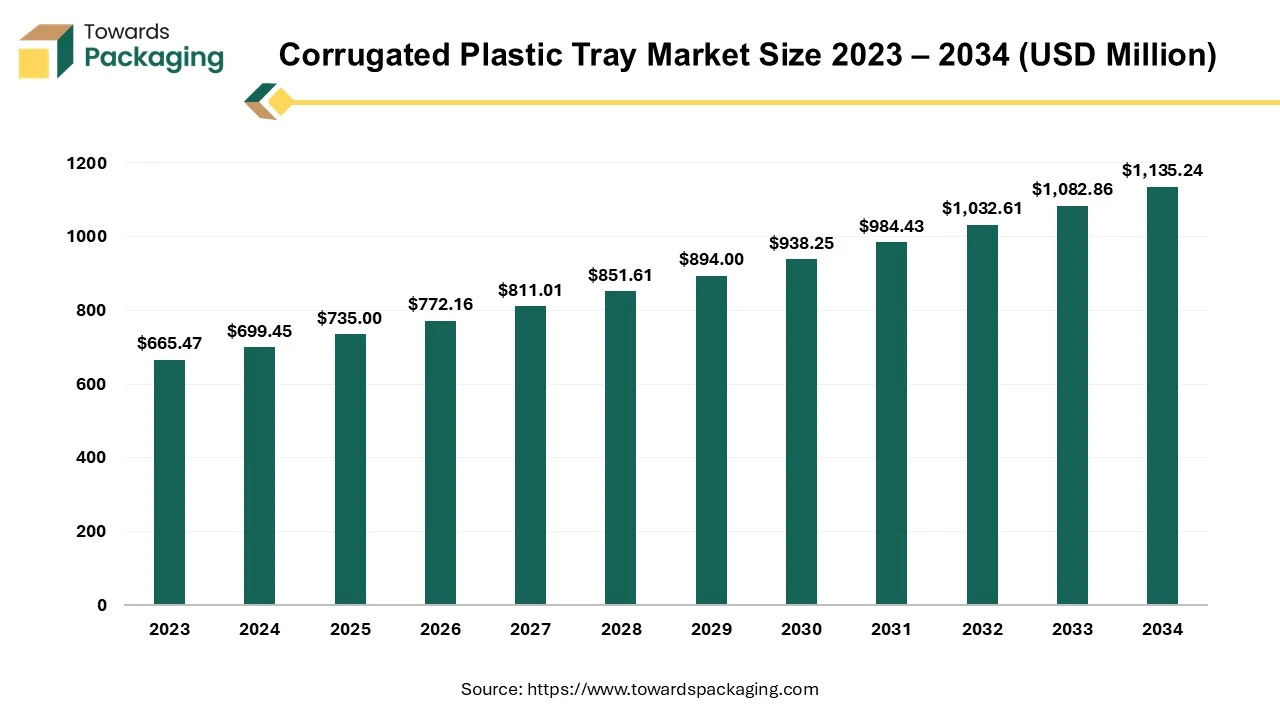

The corrugated plastic tray market is forecast to grow from USD 735.00 million in 2025 to USD 1135.24 million by 2034, driven by a CAGR of 5.14% from 2025 to 2034.

The corrugated plastic trays are manufactured out of light-weight tough material. Corrugated plastic trays are chemically inert and resistant to impacts and water. It is 100% recyclable and reusable. The corrugated plastic tray has ability to withstand cold environments and humidity. The use of corrugated plastic tray is easier to handle and offers low costs as transportation fair as it is light in weight. A corrugated plastic tray is a type of packaging product made from corrugated plastic material, typically polypropylene or polyethylene. It features a structure similar to cardboard but is made from plastic, which provides added durability, moisture resistance, and strength.

AI is capable of analyzing production data to optimize manufacturing procedures, increasing quality control, decreasing waste, and increasing efficiency. By predicting equipment problems before they happen, AI-powered predictive maintenance can also reduce downtime. By examining consumer preferences and usage trends, AI-driven design tools can help create creative tray designs. This makes it possible to better customize and create trays that better satisfy particular requirements.

AI can improve supply chain logistics through better inventory management, demand prediction, and procurement procedure optimization. This guarantees timely material availability and lowers the price of stockouts or overstocking. Algorithms that use machine learning to identify flaws or irregularities in trays during manufacturing might improve quality control. When compared to manual examinations, automated inspection systems are able to spot problems faster and with more precision.

AI can give businesses insights into consumer behavior and industry trends, enabling them to better predict demand and modify their business plans accordingly. This may result in better strategic planning and decision-making. By monitoring client feedback to enhance service quality and product offerings, as well as by making personalized recommendations and recommendations, artificial intelligence (AI) can enhance customer contact.

By maximizing material utilization and encouraging recycling and reusability, AI can assist in the creation of more environmentally friendly goods that are in line with sustainability objectives. Businesses in the corrugated plastic tray sector can increase productivity, improve product quality, and respond more quickly to customer requests by incorporating AI into various elements of their operations.

The demand for the corrugated plastic trays is rising due to qualities such as durability and resistance to moisture, chemicals, and physical damage, making them ideal for various industrial and commercial applications. Their reusability and recyclability align with growing environmental concerns and sustainability initiatives, attracting companies looking for eco-friendly packaging solutions. Despite higher initial costs, the long-term cost benefits due to their durability and reusability can make corrugated plastic trays more cost-effective compared to single-use alternatives. The rise in e-commerce and retail activities increases the demand for reliable and efficient packaging solutions to ensure safe and effective product delivery.

Technological improvements in production processes enhance the efficiency and performance of corrugated plastic trays, making them more attractive to various industries. The ability to customize corrugated plastic trays for specific sizes, shapes, and applications allows them to meet diverse industry needs, driving broader adoption has risen the demand for the corrugated plastic tray in the market. The key players operating in the market are focused on market expansion by establishment of new plant and expansion of market presence, which is estimated to drive the growth of the market over the forecast period.

For instance,

The project, which was announced in January 2024, is now under development with an anticipated $140 million investment. It will boost WestRock's capacity for production and raise its cost structure in this important region. To construct their building at LogistiCenter*, a logistics and distribution center at Pleasant Prairie, WestRock went into a build-to-suit lease arrangement with Dermody Properties, a national real estate investment, construction, and management company that specializes in logistics real estate. The project's groundbreaking ceremony took place in June 2024. It is projected that the facility will be finished in 2025. After that, WestRock intends to shut down its North Chicago plant and move its activities to the new location.

The high cost of initial deployment of technology for manufacturing corrugated trays is becoming concern for growth of the corrugated plastic tray market. The cost of manufacturing corrugated plastic trays, including the investment in specialized machinery and raw materials, can be higher compared to traditional materials like cardboard. Advances in manufacturing technology are required to improve the cost-effectiveness and performance of corrugated plastic trays. Lagging technology could hinder growth potential. Other packaging materials, such as biodegradable options and traditional cardboard, may offer lower costs or specific advantages that compete with the benefits of corrugated plastic trays. Despite being reusable, plastic products face criticism regarding their environmental impact.

Regulatory pressures and consumer preference for more sustainable materials can limit market growth. In some regions, the market may be saturated with existing players, making it difficult for new entrants to gain a foothold or for companies to expand without significant investment. Some consumers may still perceive plastic products negatively due to their association with environmental issues, impacting demand. Addressing these challenges involves focusing on technological advancements, improving sustainability practices, and responding to evolving market preferences.

The demand for efficient logistics and supply chain solutions is increasing. Corrugated plastic trays are ideal for transporting goods due to their durability and ability to handle various environmental conditions. Efficient supply chain and logistics management benefits from the use of corrugated plastic trays due to their stackability, durability, and ease of handling has risen the demand for the corrugated plastic tray. The ability to customize corrugated plastic trays for different applications and industries offers opportunities for growth in diverse sectors such as food and beverage, pharmaceuticals, and electronics. The key players operating in the market are focused on developing new innovative corrugated plastic tray solutions for logistics and supply chains due to rising demand for lightweight packaging solution, which is estimated to create lucrative opportunity for the growth of the corrugated plastic tray market over the forecast period.

For instance,

Bobst is exhibiting its most recent flexible packaging solutions at Drupa 2024, including a brand-new device for improved automation and digitalization. The gravure printing process necessitates significant setup time and fine tuning, which calls for advanced operator skills. This is where the Smartgravure breakthrough comes in. The business claims that Smartgravure may improve productivity and output consistency, decrease downtime and complexity, and provide sustainability advantages with its automated color management, digitalized setup and controls, and communication with Bobst Connect.

The BOBST company unveiled two significant new Bobst Connect capabilities during the event: Customers can easily incorporate Bobst machines into their production and design workflows with Workflow with Job and Recipe Management. Bi-directional job and recipe data synchronization facilitates quick setup times and higher productivity. Meanwhile, by gathering data from a variety of tasks, settings, and linked devices, the Energy Monitoring function enables users to monitor their energy expenses and consumption in real-time.

The polyethylene (PE) segment dominated the market in 2024. As the polyethylene corrugated plastic tray is lightweight and strong at the same time, it safeguards goods during handling and transportation while minimizing shipping expenses. The companies trying to cut costs on manufacturing and packaging are attracted to polyethylene corrugated packaging because it is frequently less expensive to create and buy than alternative materials. This kind of packaging is very adaptable and works well with a variety of products, including consumer and industrial goods. Because of its adaptability, size and shape can be customized. Since polyethylene doesn't easily absorb moisture, it helps shield goods from harm during shipping and storage from moisture and humidity, the polyethylene corrugated plastic tray are widely used for packaging eggs, fruits, vegetables and pharmaceutical products.

When compared to certain other materials, polyethylene is a more sustainable option because it can be recycled. Branding and product details can be directly printed on polyethylene corrugated packaging, making it an easy option for printing. The key players operating in the market are focused on launching new polyethylene corrugated plastic tray to meet the rising demand of the corrugated plastic tray which is estimated to drive the growth of the segment over the forecast period.

For instance,

The rectangular held a significant share in the market in 2024, the segment is estimated grow at significant rate over the forecast period in 2024. The rectangle shaped corrugated plastic tray are extensively used as they fit well on shelves, pallets and in containers, optimizing space utilization. The rectangle shape of the corrugated plastic tray offers the consumer large space to feet its products well inside tray.

Moreover, the rectangular shape simplifies manufacturing and design processes and are easier to handle at the same time. The food industry is launching new food products which requires particularly rectangular shaped corrugated trays for packaging which is estimated to drive the growth of the market over the forecast period.

For instance,

The agricultural segment held the dominating share of the corrugated plastic tray market in 2024. As the corrugated plastic tray are chemical inert and resistant to moisture they widely used in the agricultural industry. The corrugated plastic tray is physical strong which makes them ideal for handling and transporting agricultural products, which often require robust and long-lasting containers.

Corrugated plastic trays are lighter than traditional materials like metal or wood, reducing shipping costs and easing handling during harvest and distribution. They offer a cost-effective solution due to their durability and reusability. They can be used multiple times, lowering the need for frequent replacements. They are easy to clean and sanitize, which helps maintain hygiene standards, crucial for storing and transporting food products safely.

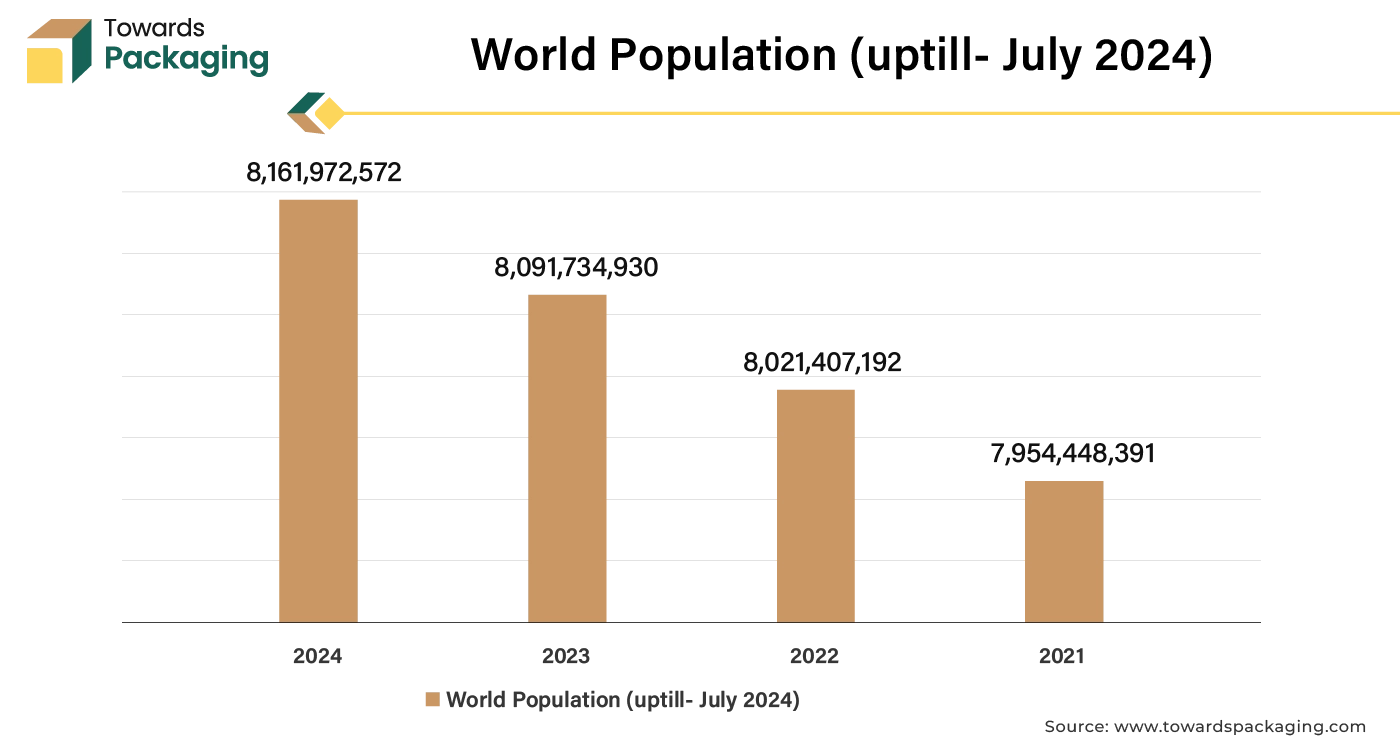

The growing global population drives higher demand of food, leading to expansion and intensification of agricultural activities to meet this need. The expansion of global trade and export opportunities allow agricultural products to reach new markets, driving growth in production and industry revenue.

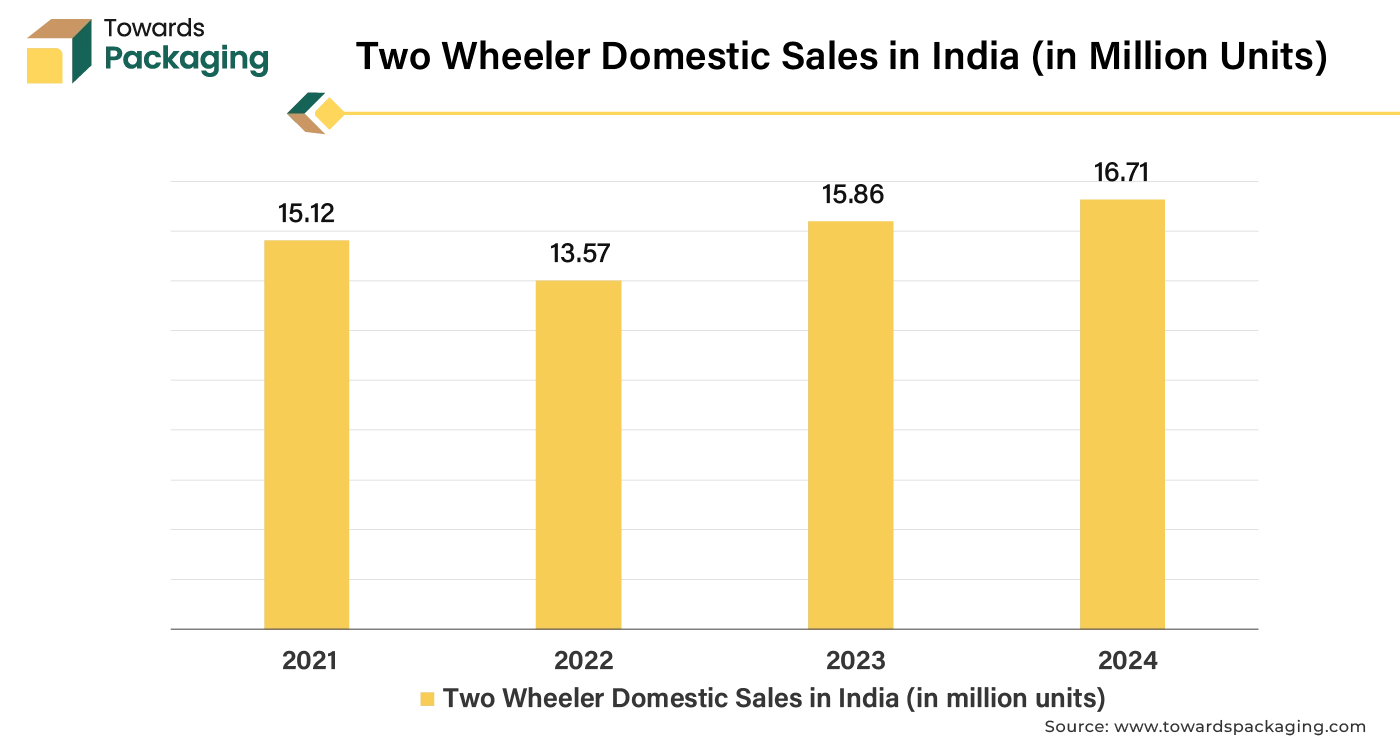

The automotive segment is estimated to grow at the fastest rate over the forecast period. Corrugated plastic trays are robust and offer protection for automotive parts during shipping and storage, reducing the risk of damage. These trays are lighter than alternatives like metal or solid plastic, which helps in reducing shipping costs and makes handling easier. Corrugated plastic is often more cost-effective compared to other materials due to its durability and recyclability, leading to lower overall expenses.

Corrugated plastic tray are designed to be reusable and can withstand multiple cycles of use, which aligns with the industry's push towards sustainability and cost savings. These trays can be easily customized in terms of size, shape, and design to fit specific parts and requirements, improving efficiency in the supply chain. As the automotive industry moves towards greener practices, corrugated plastic trays, which are often recyclable, align with these environmental goals. Due to rise in the disposable income the sales of vehicles has increased. The increasing sales of vehicles has fuel up the automotive industries which has grown the demand for the corrugated plastic tray and is estimated to drive the growth of segment over the forecast period.

For instance,

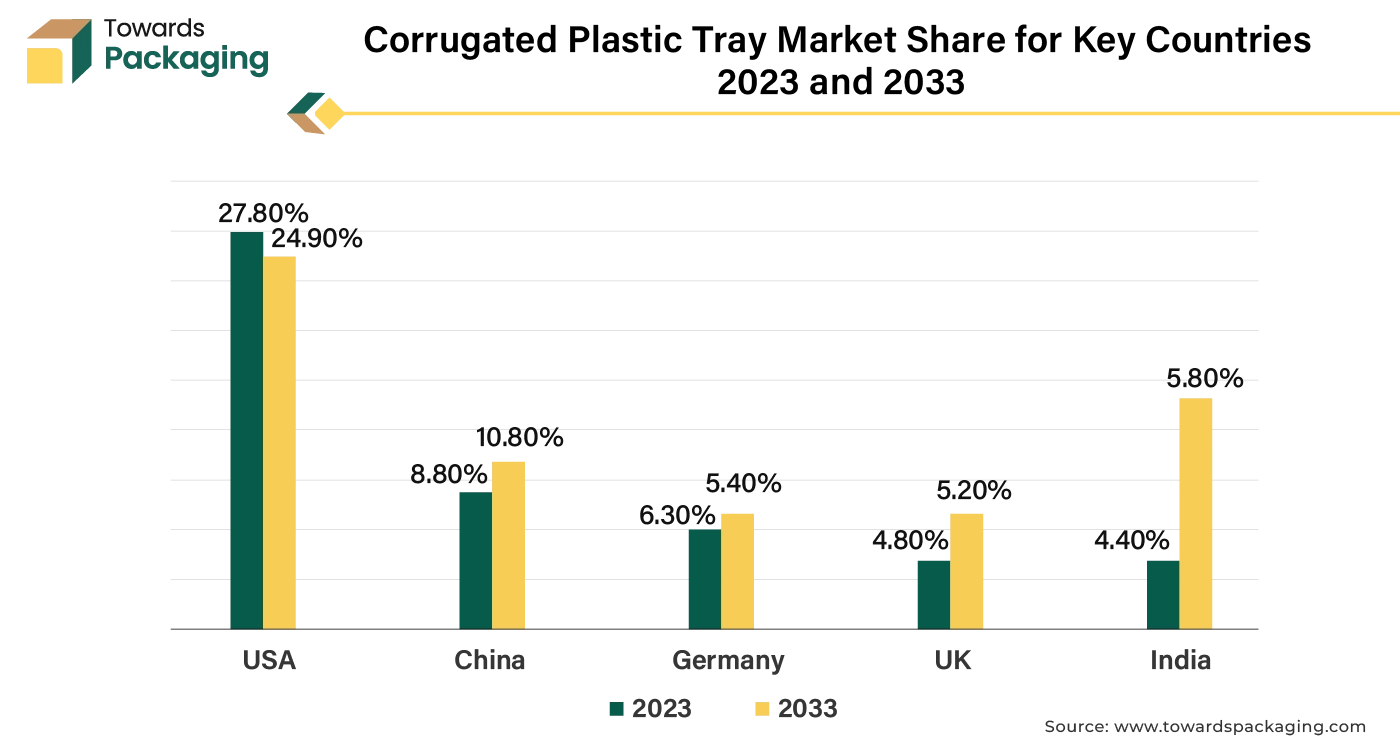

Asia Pacific held the dominating share of the corrugated plastic tray market in 2024and is observed to sustain the position over the forecast period. The Asia Pacific region’s ongoing industrial growth and increasing urbanization are driving demand for the efficient packaging solutions. The rapid development of electronics as well as automobile the industries in the India, China and Japan are responsible for the rise in the demand of corrugated plastic tray. India constantly growing its agriculture market and due to this the demand of corrugated plastic trays for storing fruits and vegetables is observed to be increased.

Corrugated plastic trays have become more in demand as a result of India's organized retail sector's recent rapid growth. Among all the sectors, the Indian retail industry stands out as one of the fastest-growing and most dynamic. The entry of overseas merchants and minor businesses in the Indian market is the primary driver of this astounding market expansion of the retail sector in India.

Demand for packaging solutions, such as protective packaging for the packing, storing, and shipping of a range of consumer and non-consumer items, is consistently generated by the retail sector. The need for corrugated plastic trays for packaging and transportation has increased as a result of the expansion of organized retail. Additionally, local and international producers of protective packaging can capitalize on this and strengthen their position in the corrugated plastic tray industry. Overall, corrugated plastic tray sales are being driven by India's growing organized retail sector, which is creating a demand for more effective and efficient packaging solutions.

North America is observed to witness a rapid pace of growth during the forecast period. Industries such as automotive and manufacturing require durable and reusable trays to handle parts and components, driving growth in this sector. There is a strong emphasis on sustainability and recycling. Corrugated plastic trays are recyclable and reduce waste, aligning with the region’s environmental goals and consumer preferences for eco-friendly products.

The growing food and beverages, agriculture and pharmaceutical industry is expected to drive the growth of the corrugated plastic tray market. The key players operating in the market are focused on adopting inorganic growth strategies like partnership to develop corrugated plastic tray, which is estimated to drive the growth of the corrugated plastic tray market in the North America region over the forecast period.

By Material Type

By Shape

By End Use

By Region

April 2025

March 2025

March 2025

February 2025