April 2025

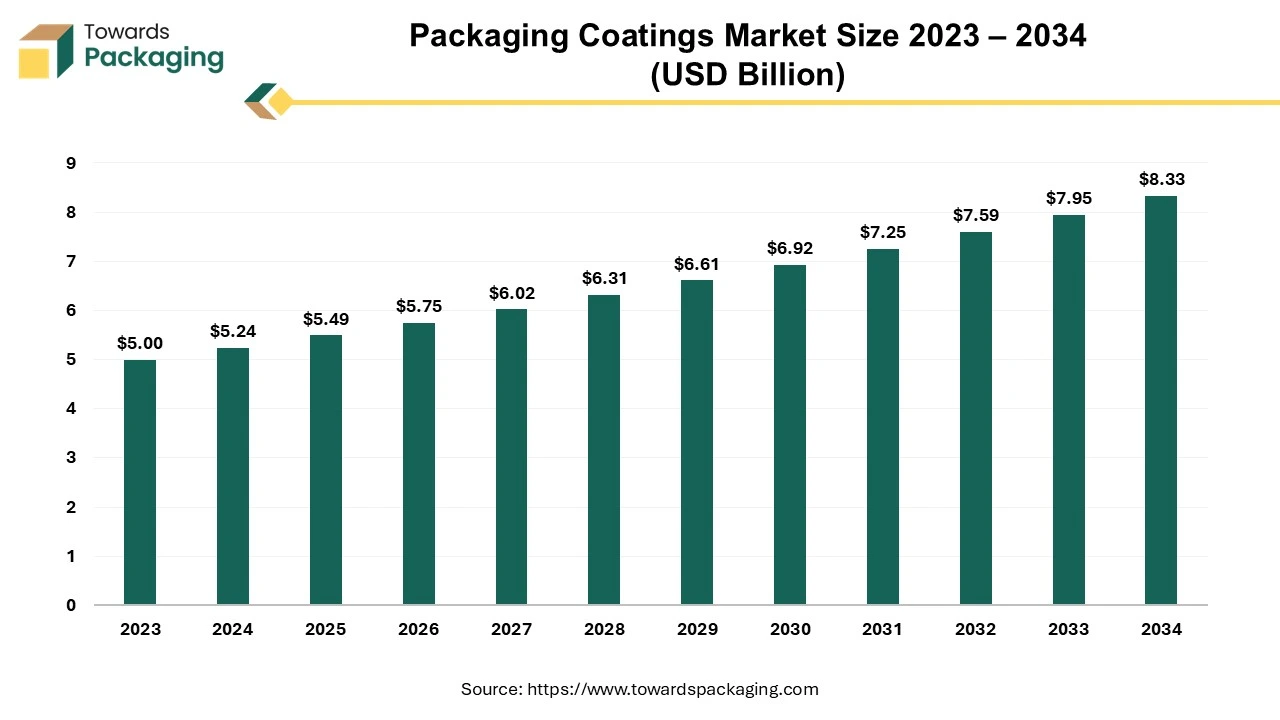

The packaging coatings market is forecast to grow from USD 5.49 billion in 2025 to USD 8.33 billion by 2034, driven by a CAGR of 4.75% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The packaging coatings market is seen to sustain its growth with the integration of advanced technologies in the market. Additionally, the rising expansion of end users is seen to support the market’s growth.

The market for packaging coatings revolves around the production of packaging that offers protection against moisture, abrasion, and fading. Along with this, reducing waste generation and ensuring product availability are the leading objectives of the market. The product safety feature also includes adequate machinability, which provides efficient packaging and also increases the profit margin of companies due to increased capacity.

The ability to provide a glossy and matte finish and thereby enhance the appearance of the product contributes to the market growth. The vibrant colors or high-resolution images ensure a velvety texture, reduce glare, and add a premium feel to the packaging. Apart from this, the demand for packaging coating spans various sectors such as luxury packaging, high-end consumer goods, and automotive packaging.

The primary function of the packaging coatings is to ensure the design of intricate packaging by using robotics, precise labeling, soft algorithms, and minimizing human errors. The implementation of packaging coating plays a crucial role in enhancing production efficiency by designing packaging that will be more durable and long-lasting. This coating barrier shields the product from scratches, scuffs, and environmental factors such as moisture and UV light. By utilizing different types of coating in the packaging sector, businesses can achieve a high level of precision in their operations, which in turn leads to more accurate order fulfillment and optimized shipping costs.

The packaging coatings market comes in various types, such as varnish coating and lamination, that are often used for product boxes, labels, and retail packaging. Furthermore, aqueous and metallic coating provides an aesthetic appearance to the products and is used in cosmetic packaging, gift boxes, and high-end retail packaging. It also ensures the integrity of the product since heat-seal coatings provide secure and tamper-evident seals.

Technological advancements are moving from traditional synthetic polymers to sustainable breakthrough materials, which will provide innovation in paper-based packaging and barrier packaging. The integration of artificial intelligence, especially for nanotechnology purposes will help in extending the shelf life with the help of nanocomposite films, which will include nanoscale particles like clay, graphene, and metal oxides into polymer matrices, and these advancements will protect products from gases, UV lights, and moisture. They will also ensure durability and flexibility, which will enhance handling designs and provide smooth transportation.

Antimicrobial solutions have also used AI to improve their basic features, like cleanliness and durability, which prevent biological degradation and reduce the growth of contaminants like mold and mildew. Adoption of AI technology by coating manufacturers will increase the use of automation processes and as a result, will increase visual inspection or chemical inspection with the help of sensors. They will also be able to check for defects with greater accuracy compared to conventional QC processes.

The major driving factor is the increasing demand for packed food as it is convenient for the consumer, given the reason the food products have extended shelf life due to strong barrier protection. The coating also ensures that the food will be protected from contamination and spoilage.

The leading challenges that hinder the growth of the packaging coatings market are higher production costs and government regulations. The high-barrier lamination processes and specialized materials required for barrier production are highly expensive. The government regulations with their time-consuming nature hinder the growth of the market. Apart from this, changes in regulations due to external factors and economic factors increase the challenge for market stability.

The packaging coatings market offers opportunities in manufacturing of coating made from bio-degradable materials and also manufacturing barrier materials which will be easily recyclable. The demand for sustainable packaging solutions which will produce less garbage holds key player’s attention increasing opportunities for eco-friendly packaging solutions.

Consumers are becoming more environmentally conscious and are actively seeking products that have minimal environmental impact. This shift in consumer behavior is driving manufacturers to adopt sustainable packaging solutions. Packaging coatings play a crucial role in ensuring the quality, functionality, and visual appeal of eco-friendly packaging.

By resins, the epoxies segment held the largest share of the packaging coatings market in 2024. Epoxy coatings are long-lasting and offer a high level of protection without frequent maintenance or replacement, making them a cost-effective solution for packaging manufacturers. The durability of epoxy-based coatings translates to fewer packaging failures and less waste over time, offering both economic and environmental benefits. Epoxy coatings exhibit excellent chemical resistance, making them ideal for packaging products that contain chemicals or products sensitive to environmental changes.

By packaging type, the flexible packaging segment dominated the packaging coatings market in 2024. It is dominating due to its properties which are robust and secure protection. The segment provides easy opening, smooth transportation, and environmental protection and can also be easily recycled or bio-degraded. Apart from this, flexible packaging can be customized and is in demand due to its features like chemical and tear and puncture resistance, heat seal ability, and moisture resistance.

By end-user industry, the food and beverage segment is the dominating segment in the packaging coatings market. The segment dominates due extended shelf life provided to the food products and the prevention of contamination. The barrier packaging depends upon the layer of coating it provides which prevents transmission of oxygen and UV rays and stops deterioration of printed information. The global consumption of packed food has increased the packaging coating demand in the food sector.

Asia-Pacific is the dominating region in the packaging coatings market. India and China being the largest populated countries dominate the market due to their market share which is driven by rapidly growing middle class and the increasing urbanized population. The ready-to-go food segment, which uses most of the packaging coating is convenient for the busy population as it reduces time consumption. Asia is home to several major packaging trade shows and industry events, such as PackEx India, Sino-Pack, and Japan Pack, where manufacturers and suppliers in the packaging coatings market showcase their innovations and collaborate. This fosters rapid growth and development within the industry.

According to the Ministry of Consumer Affairs of India, the increasing number of working classes, lack of time for food preparation, increasing number of senior citizens, and lastly, the changing food habits have led to the increase of packed food consumption, in result, boosting the packaging coatings market which will provide a robust and secured packaging to the food products.

Asian countries have stringent regulations for food safety, which influences the packaging industry. Coatings must meet strict standards for compliance, which has led to significant investment in research and development for specialized coatings that can meet regulatory requirements in different countries.

North America is the fastest-growing region in the market. North America is the fastest-growing market, given the reason it has steady growth due to its consumer preferences which are driven by sustainability and convenience. North America, particularly the United States and Canada, has a large and established consumer base with high levels of disposable income. This drives demand for packaged goods, including food and beverages, pharmaceuticals, cosmetics, and consumer electronics. The packaging industry in North America, particularly in the food and beverage sector, is a critical area where high-quality coatings are required for product protection, shelf life extension, and aesthetic appeal.

According to USDA ERS, American consumers spend an average of 11.2% of their disposable income on food sector which gives rise to packaging market. In contrast, low-income households depend on ultra-processed foods due less time-consumption and extended shelf life of packed food. The American population consumes packed food on daily basis and the US food system is dominated by packed food to preserve and ensure food safety, American companies are developing innovative packaging coating solutions.

Resins

Packaging Type

End-user

Regional

April 2025

April 2025

April 2025

April 2025