April 2025

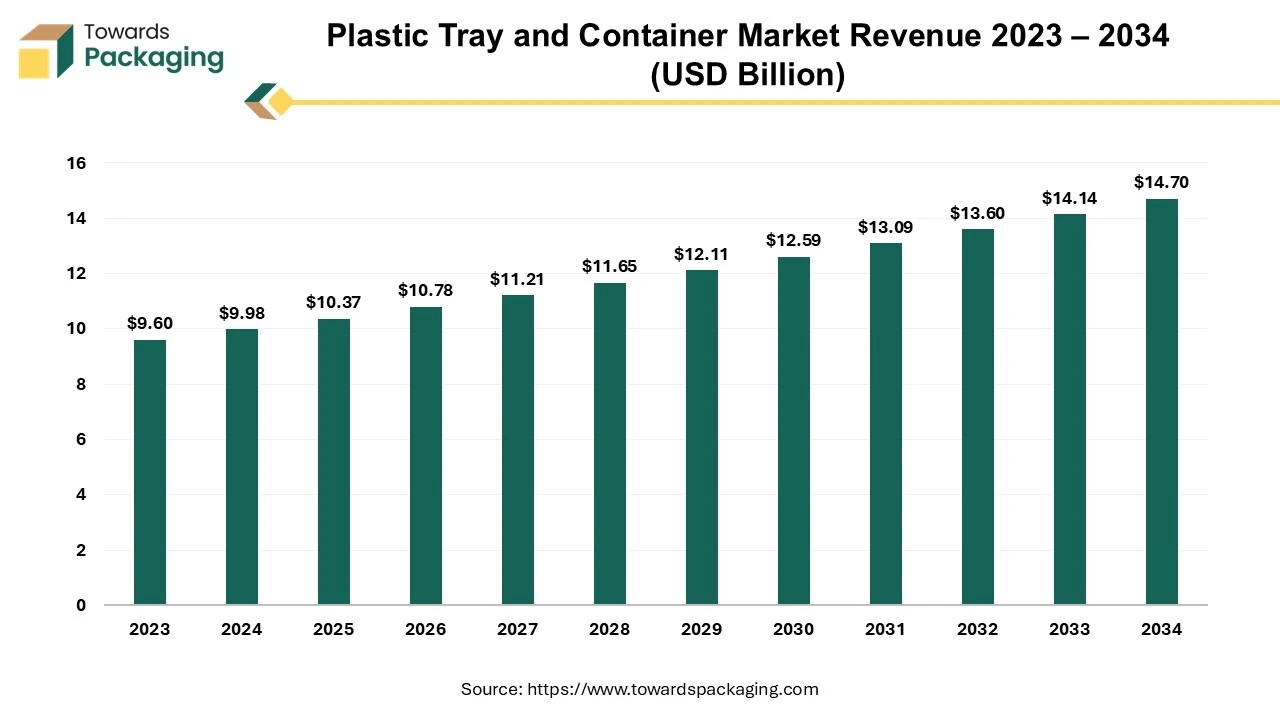

The plastic tray and container market is forecasted to expand from USD 10.37 billion in 2025 to USD 14.70 billion by 2034, growing at a CAGR of 3.95% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The market is proliferating due to the increasing business retail market of food& beverage, healthcare services, horticulture, e-commerce, personal care & cosmetics, hotels & cafes, catering, offices, bakeries, and many others which require plastic trays and containers for storage, packaging and delivery purposes. The growing trend of online ordering facilities is boosting the plastic tray and container market.

The plastic tray and container market is in high demand as numerous market players prefer this due to its affordability. These trays and containers are useful in several ways as they are sturdy, moisture-resistant, and lightweight, making them perfect for storing and transporting various products. The need for plastic packing is rising due to its accessibility, artistic visuals, and advanced environment-friendly choices. The plastic tray and container market is observing noteworthy development, determined by the accessibility of advanced, inexpensive, and sustainable packaging results.

These can be modified easily according to the purpose of different industries and also to encourage brands. Plastic trays and containers provide excellent quality protection against oxygen and water vapour to the food items and beverages packed. As businesses are continuously prioritizing sustainable and recyclable products this plastic tray and container market is anticipated to grow in upcoming times with an effort on recycling materials and ecological packaging solutions. The global packaging industry size is growing at a 3.16% CAGR.

Recyclable plastic trays and containers are in high demand in the market as these are useful for numerous purposes. With the rapid growth of the consumer goods, food & beverage industry, cosmetic industry, and many others have started shifting toward better packaging possibilities that are recyclable, lightweight, safe and sustainable for transporting purposes. Plastic tray and container packaging is well-known for its sturdiness and, confirms that foods are tightly packed and endangered.

Whether it is about the hustle while transporting goods or the push while shopping with carts, plastic containers are suitable in all cases. Furthermore, it is lightweight which makes it preferable for several uses. Apart from food & beverages, in the personal care and cosmetics industry, polypropylene is extensively used for manufacturing jars and bottles for packaging powders, creams, and various other cosmetic products. The durability and compact size of such containers protect products from light, dust, air, moisture, and dirt, confirming the integrity of the packaging.

In the pharmaceutical sector, earlier glass containers were widely used for packaging purposes of medicines, drugs and vaccines. But now it has shifted towards plastic trays and containers as they are considered easier to use, lightweight, resistant to leakage, and cost-effective in comparison to glass packaging. The major chosen materials in the healthcare sector for trays and containers are polypropylene, polystyrene, polyethene, and polyvinyl chloride. Plastic-based trays and containers are chemically inactive and unaffected by corrosion this quality protects the medicines and drugs and increases their shelf-life.

Hence, the speedily rising pharmaceutical sector will boost the demand in the predicted period. The air management system is of supreme position in these situations, continuing the essential antiseptic and sterile situations as well as superior quality access and covering measures. Enhanced-quality plastic trays and containers are widely used by the pharmaceutical sector for drug and vaccine packaging. Polyethylene works as a good barrier against several germs that keep products contamination-free.

The decay of plastic material is slower in comparison to the quantity it is produced every year. The recycling procedure of plastic trays and containers is an extensive procedure that comprises melting, selling, resolving, and shipping. Moreover, chemicals used in making plastic are dangerous and can generate toxic waste.

Asia Pacific witnessed the highest revenue share for the year 2024. This packaging material is in high demand in food & beverage packaging as it is non-toxic and keeps food safe while transporting. Its property of resistance to moisture, dust, dirt, and any external factors makes it the most preferable packaging solution for the food industry. Rising food & beverage firms have a direct influence on the plastic tray and container market.

The wide expansion of e-commerce mobile applications has provided ease to consumers for ordering online food products which enhances this market. Developing countries such as India, China, Japan, South Korea, and Thailand are progressively working toward innovative facilities for online orders of food and also sustainable measures for plastic products.

North America is estimated to grow at the fastest rate over the forecast period. The growing demand for online order systems in the e-commerce business comprises several factors such as rising inhabitants, economic situations, start-up culture, expansion, and many others. The demand for such plastic trays and containers for packaging purposes is growing in this region as these are cost-effective choices as well as provide progressive security to any type of delicate substances which makes them perfect for shipping.

With the progress of the e-commerce sector, there has been a massive upsurge in the capacity of products that are essential to be delivered, which has resulted in a continuous expansion in the demand for the packaging of materials. This has formed various new openings for the plastic tray and container market, with several market players emerging with new packaging initiatives that are only designed for e-commerce product shipment.

By type, the PP segment led the plastic tray and container market in 2024. These polypropylene trays and containers are in demand widely due to their versatile, durable and lightweight nature. These are widely used in all sectors such as pharmaceuticals, consumer goods and food & beverages as these are suitable for maintaining both high and low temperatures. Innovation in packaging techniques has improved the performance of PP products. The growing trend of ready-to-eat food has also driven this market as it requires air-tight packaging solutions.

By application, the agriculture packaging trays and containers segment led the plastic tray and container market in 2024. These products are majorly used in seedling propagation, plant delivery, and packaging agriculture products. Biodegradable plastic trays and containers are highly preferred in this sector due to sustainable practices in the agriculture field. The growing influence of greenhouse farming and vertical agriculture enhances the demand for special trays and container patterns which are precisely manufactured for crops.

By Type

By Application

By Region

April 2025

April 2025

April 2025

March 2025