May 2025

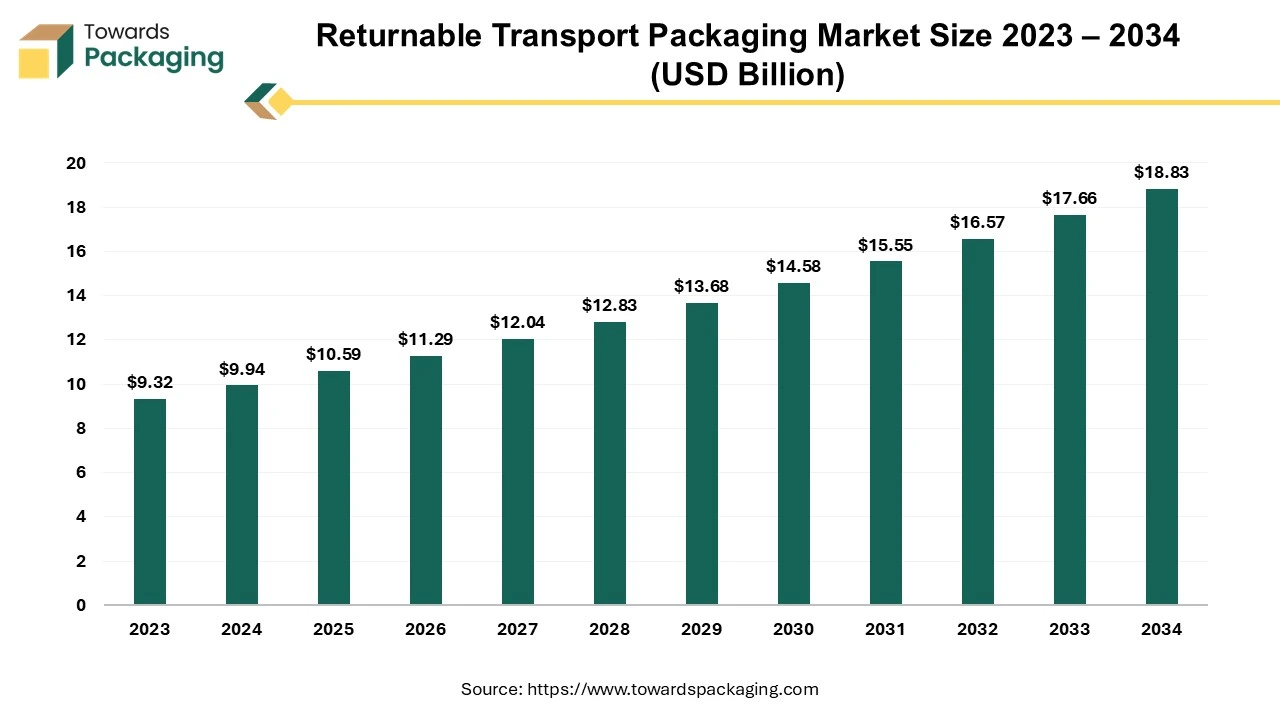

The returnable transport packaging market is projected to reach USD 18.83 billion by 2034, expanding from USD 10.59 billion in 2025, at an annual growth rate of 6.6% during the forecast period from 2025 to 2034.

The market for returnable transport packaging has expanded dramatically in recent years due to the growing need for economical and environmentally friendly shipping options. Packing supplies such as pallets, bins, totes, boxes, and containers that may be reused several times for transferring goods between suppliers and consumers are referred to as returnable transport packing or RTP. Organizations use returnable containers, pallets, and pallet pooling systems more frequently to enable repeated transport journeys in managed open-loop and closed-loop shipping systems. Because they are sturdy materials, these returnable packing options can be used repeatedly during reverse logistics.

The market for returnable transport packaging has grown considerably in recent years as there is a greater demand for cost-effective and ecologically friendly shipping choices. Returnable transport packing, or RTP, refers to packaging supplies such as pallets, bins, totes, boxes, and containers that can be reused numerous times when carrying goods between suppliers and consumers. Organizations increasingly use returnable containers, pallets, and pallet pooling systems to facilitate repeated transportation journeys in managed open-loop and closed-loop shipping systems. Because they are made of durable materials, these returnable packing choices can be reused throughout the reverse logistics process.

For Instance,

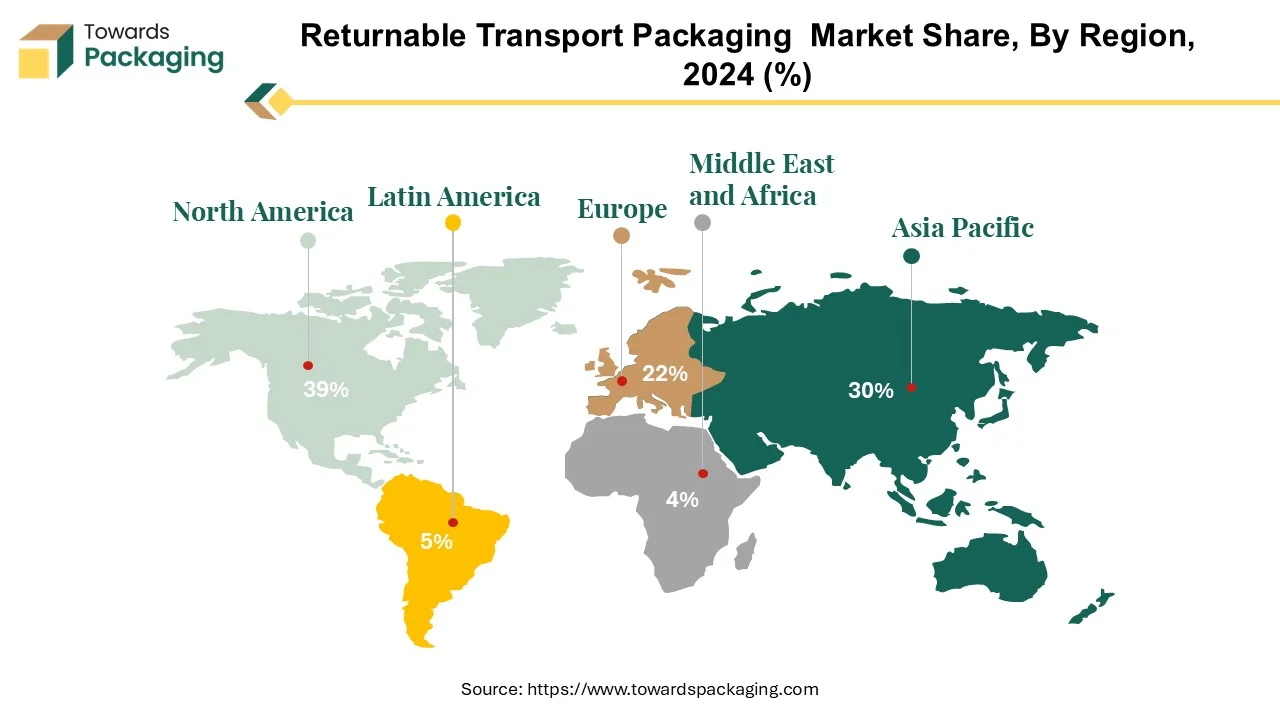

North America is a market leader in Returnable Transport Packaging (RTP) for various reasons. Its well-developed logistics and transportation infrastructure, which includes large highways, railways, ports, and distribution networks, enables efficient and cost-effective packaging solutions. This sturdy infrastructure allows for the smooth movement of commodities across long distances, promoting the use of RTP. The region strongly emphasizes sustainability and environmental responsibility, which has increased demand for returnable packaging. Legislation such as California's SB-54, which aims to reduce single-use plastics and promote recycling, reflects this determination. Such campaigns encourage businesses to use returnable packaging, allowing numerous trips and longer product life cycles.

North America is home to various businesses, including automotive, retail, food and beverage, and manufacturing, which rely substantially on reliable transportation. These industries require robust packaging solutions to ensure their product's safe and secure transit, contributing to the increased demand for RTP solutions. The presence of top manufacturers and suppliers of returnable packaging solutions strengthens North America's market position. These companies provide new products and services targeted to the specific demands of businesses in various industries.

North America leads the global returnable transport packaging market because of its sophisticated infrastructure, sustainability initiatives, various sectors, and vital market participants.

For Instance,

Asia Pacific is developing as the fastest-growing area in the Returnable Transport Packaging (RTP) market due to several important factors. The region is rapidly industrializing and urbanizing, increasing the need for efficient transportation and logistics solutions. As businesses expand their operations and supply chains throughout Asia Pacific countries, there is an increasing demand for dependable and cost-effective packaging solutions to allow product transit.

In addition, there is a growing awareness in the Asia Pacific region of the importance of environmental sustainability and waste reduction. Governments and regulatory agencies are enacting regulations and programs to encourage returnable packaging solutions as part of more extensive efforts to prevent pollution and promote eco-friendly behavior. This emphasis on sustainability encourages firms to use RTP solutions that provide repeated trips and extended product lifecycles, lowering their environmental effect.

In Asia Pacific, the e-commerce business is expanding at a rapid pace, driven by rising internet penetration and customer demand for online shopping. This expansion has increased the volume of commodities across the region, increasing demand for efficient and long-lasting packaging solutions such as RTP.

For Instance,

Plastic has emerged as the fastest-growing material in the Returnable Transport Packaging (RTP) industry for several reasons. For example, plastic-corrugated packaging uses extruded twin-wall plastic sheets produced from high-impact polypropylene, polyethylene, or other plastic resins. These materials have a corrugated fiberboard-like structure, with fluted ribs supporting upper and lower surfaces. This design uses solid panels and sleeves to manufacture a diverse range of returnable product types, including handheld boxes and bulk bins.

In 2023, 44% of Primary Users predicted that their companies' use of plastic-corrugated packaging will grow during the next five years. The advantages of plastic packaging, such as lightweight, recyclability, and durability, are driving its increasing popularity. Plastic pallets, for example, are lighter than other materials, making them more convenient to move and handle. Similarly, plastic trays, such as those offered by Euro Pool System, are ideal for use in the European fresh produce supply chain because of their lightweight design, simplicity of mobility, and high-quality plastic composition, which ensures lifespan.

Plastic materials' adaptability, durability, and recyclability make them particularly appealing for use in returnable transport packaging, resulting in their rapid adoption and becoming the fastest-growing material in the RTP industry.

For Instance, In January 2024, the introduction of Dora, a cutting-edge Returnable plastic pallet, throughout Europe was announced by IFCO, the world's foremost supplier of Returnable Packaging Containers (RPCs). Dora, which is offered through IFCO's circular model pooling system and was specifically created for RPC compatibility, integrates easily into the current fresh food supply chain operations, ensuring long-term improvements in logistical efficiency and sustainability for both suppliers and retailers.

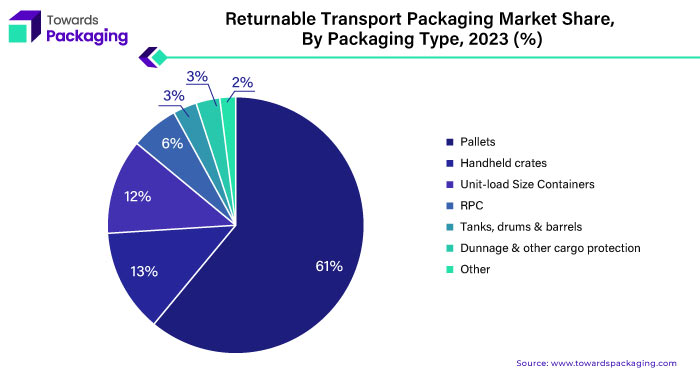

The largest Returnable Transport Packaging (RTP) market segment consists of mobile, horizontal, rigid composite platforms utilized as a base for assembling, storing, stacking, handling, and transporting items as a unit load. This category includes both pooled and one-way wood transactions because all pallets—regardless of durability—must be repaired and reused for a more extended period. A 2023 survey indicates that 78% of Primary Users believe their organizations will utilize pallets more frequently over the next five years.

Pallet trends are constantly aimed towards lowering costs and increasing sustainability. Efforts have been made to investigate ways to reduce pallets' weight and material utilization per trip while enhancing performance and recyclability at the end of their lifespan. However, the lightest pallet may sometimes be the most sustainable or cost-effective alternative. A more robust and long-lasting pallet may eventually reduce mass per trip over its lifetime, making it more sustainable and cost-effective in the long run, assuming other criteria are met. As a result, the emphasis on pallet design and utilization is changing towards achieving a mix of durability, sustainability, and cost-effectiveness.

For Instance,

The industrial sector is prominent among end users in the Returnable Transport Packaging (RTP) market. Electronics, manufacturing, and automobile industries rely primarily on effective logistics and transportation networks to move their goods. These sectors may ship their goods more affordably and sustainably while maintaining product security and safety using returnable packaging options. Industrial supply chains' large volume and repetitive nature are ideally matched with RTP systems' robust and returnable nature.

By implementing returnable packaging, industrial businesses can minimize waste production, cut total transportation costs, and lessen their dependency on single-use packaging materials. Because of this, there is still a high demand for returnable transport packaging solutions worldwide from the industrial sector.

For Instance,

The competitive landscape of the returnable transport packaging market is dominated by established industry giants such Nefab AB, IFCO Systems., Rehrig Pacific Company, Schoeller Allibert Group BV, SSI Schaefer Group, CSI Sertapak Inc., Lamar Packaging Systems, Polymer Logistics NV, Mugele Group, Orbis Corporation and Brambles Limited (CHEP). These giants compete with upstart direct-to-consumer firms that use digital platforms to gain market share. Key competitive characteristics include product innovation, sustainable practices, and the ability to respond to changing consumer tastes.

Nefab provides a selection of returnable and disposable packaging options. These consist of steel containers, racks, export packaging, foam cushioning, ESD (Electro Static Discharge) materials, folding no-nail boxes, collapsible wooden crates, wooden pallet collars, VCI packaging, and a range of bespoke packaging choices.

For Instance,

IFCO has the broadest product offering of pooled returnable packaging solutions of any provider. We offer Returnable Packaging Containers (RPCs) in various sizes to fit all types of fresh food. They offer optimized methods for fresh fruit and vegetables, bananas, animal products, and seafood such as shellfish, eggs, and baked.

For Instance,

By Material

By Product

By End Use

By Region

May 2025

May 2025

May 2025

May 2025