April 2025

.webp)

Principal Consultant

Reviewed By

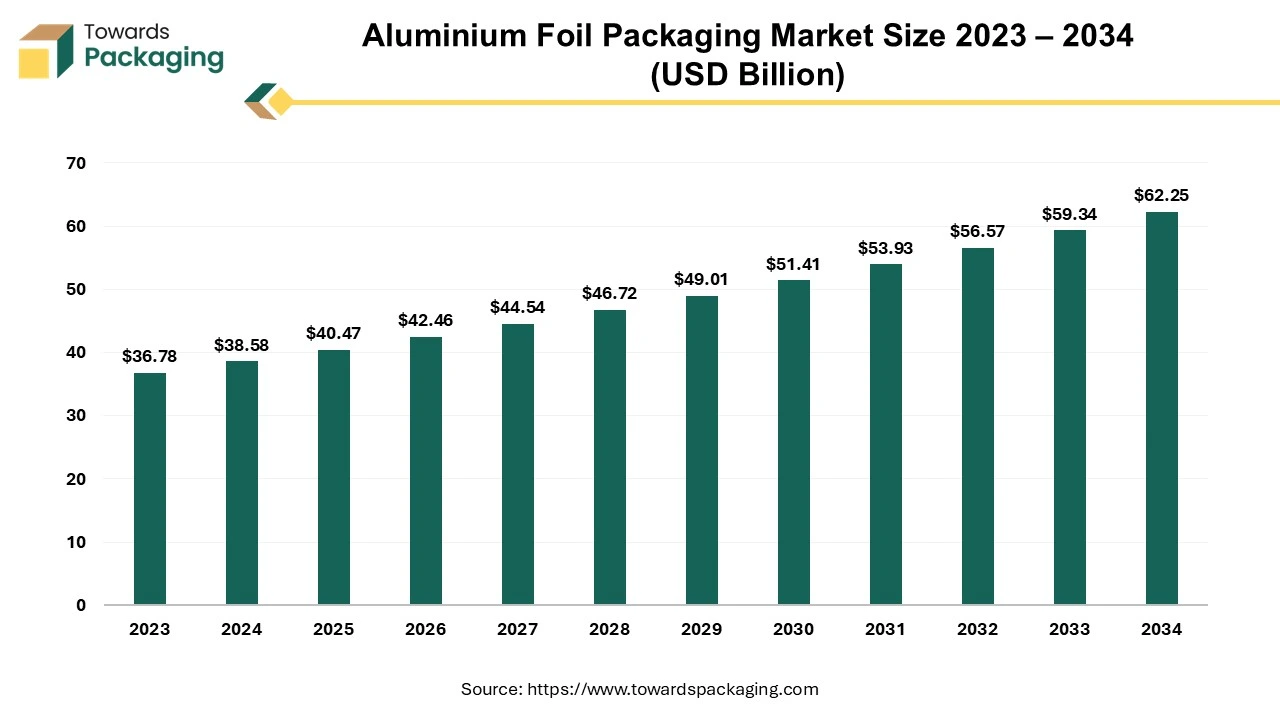

The global aluminium foil packaging market size reached US$ 38.58 billion in 2024 and is projected to hit around US$ 62.25 billion by 2034, expanding at a CAGR of 4.9% during the forecast period from 2025 to 2034. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing aluminium foil packaging which is estimated to drive the global aluminium foil packaging market over the forecast period.

Aluminium foil packaging is an extensively utilized material in various industries, including cosmetics, food, pharmaceuticals, and industrial applications. It offers high barrier protection, lightweight properties, and sustainability advantages, making it a preferred choice for cold chain packaging and temperature-sensitive products. The aluminium foil packaging acts as a barrier against moisture, oxygen, bacteria and light, preventing spoilage and degradation. The aluminium foil packaging reflects heat and light, maintaining product freshness in cold chain packaging.

Governments and brands are eliminating non-recyclable plastic-aluminium laminates and shifting to 100% recyclable aluminium. Mono-material aluminium packaging is gaining traction for better recycling. Companies are developing bio-based coatings (e.g., cellulose, plant-derived polymers) to replace plastic linings. These coatings reduce environmental impact while maintaining aluminium’s barrier properties. Thinner yet stronger aluminium foils reduce raw material usage, cutting costs and carbon footprint. Lightweight foils improve transport efficiency and sustainability. Aluminium-based insulated pouches & thermal liners are evolving for biologics, vaccines, and frozen food deliveries. Phase Change Material (PCM) integrated foils help maintain temperature stability. RFID & NFC tags embedded in aluminium packaging enable real-time temperature & freshness monitoring. QR codes on aluminium packaging enhance traceability & anti-counterfeiting for pharma & premium food brands.

Luxury brands (chocolates, spirits, cosmetics) use textured & metallic-finish foils for premium appeal. Customized color coatings & laser-engraved designs add branding value. High-resolution, flexible digital printing allows for small-batch, personalized packaging. The aluminium foil packaging reduces the need for additional labels, cutting costs & waste.

The aluminium foil packaging is mainly used for wine, cocktails, juices, and dairy as an alternative to plastic & glass bottles. Reclosable & recyclable aluminium pouches are becoming mainstream. Brands are replacing plastic wrappers with ultra-thin aluminium foils for chocolates, biscuits, and energy bars. The aluminium foil packaging are minimalist, plastic-free designs attract eco-conscious consumers.

European Union’s Circular Economy Action Plan is pushing for 100% recyclable and reusable packaging by 2030. Bans on multi-layer plastic-aluminium composites are forcing manufacturers to develop new mono-material aluminium solutions. Extended Producer Responsibility (EPR) laws are pressuring brands to use low-carbon, sustainable aluminium sources.

The aluminium foil packaging industry is evolving with the integration of Artificial Intelligence (AI). AI enhances efficiency, quality control, sustainability, and supply chain management, making packaging smarter, more cost-effective, and environmentally friendly. AI-driven robotics improve precision in cutting, embossing, and lamination of aluminium foil. Automated defect detection using computer vision ensures high-quality production with minimal waste. Predictive maintenance prevents machine breakdowns, reducing downtime and operational costs. AI analyzes production data to optimize foil thickness and material usage, cutting excess waste. Digital twin technology simulates manufacturing processes to reduce trial-and-error in new product designs.

AI-powered image recognition and machine learning detect micro-cracks, uneven coatings, or perforations in aluminium foil packaging. Real-time monitoring improves consistency, reducing defects in food, pharmaceutical, and industrial packaging. AI enables automated adjustments in production lines, ensuring uniform thickness and barrier properties. AI-integrated RFID & QR codes in aluminium foil packaging provide real-time tracking and authentication for pharmaceuticals and premium products. AI-powered freshness indicators detect temperature changes in cold chain packaging for food and vaccines.

AI helps develop biodegradable coatings and recyclable aluminium laminates, replacing plastic-based solutions. Predictive analytics optimize energy-efficient production methods, lowering the carbon footprint. AI forecasts demand fluctuations in aluminium foil packaging for food, pharmaceuticals, and e-commerce. AI-powered temperature tracking ensures optimal conditions for frozen and perishable goods. AI helps packaging companies analyze consumer data, market trends, and sustainability demands for better product innovations. AI-powered designs create interactive and consumer-friendly packaging.

E-commerce grocery platforms (Amazon Fresh, Walmart+, Carrefour Online) are driving demand for foil-based insulated packaging. Meal kit brands like HelloFresh and Blue Apron use aluminium foil pouches for food freshness. Foil-laminated stand-up pouches, resealable bags, and high-barrier films are widely used in coffee, pet food, and protein powders. Growth in the Ecommerce business has increased the demand for aluminium foil packaging which has driven the growth of the aluminium foil packaging market in the near future.

In January 2025, according to the data published by the Ecommerce Bussiness Association, in 2024, the leaders of the commerce industry spent US$3.5 billion on advertising, with individual spending ranging from US$41.3 million to US$1.7 billion. Amazon spent the most, spending $1.7 billion, more than four times Walmart's total. Aliexpress spent the least, spending only US$322,000, 5,000 times less than Amazon. This is primarily because Aliexpress is more popular outside of the U.S. than it is in the U.S., but even with such low spending, Aliexpress.com has seen a remarkable increase in website traffic in the states.

Governments are phasing out non-recyclable or non-reusable packaging, affecting plastic-aluminium laminates. Extended Producer Responsibility (EPR) laws force companies to invest in sustainable alternatives, increasing costs. Some regions are restricting or banning aluminium packaging for single-use applications (e.g., foil wraps, takeout containers). Plastic-free packaging trends are driving brands toward alternative materials like biodegradable paper coatings. Paper, glass, and bioplastics are emerging as alternatives due to their eco-friendly image. Many food and beverage brands are exploring compostable or fiber-based packaging instead of aluminium. Reusable stainless steel, glass, and polymer containers are reducing demand for single-use aluminium packaging. Recycling challenges make it less attractive than fully circular alternatives.

Global plastic bans and environmental regulations are pushing industries to adopt 100% recyclable aluminium foil as a sustainable alternative. The European Green Deal, China’s plastic reduction policies, and the U.S. Plastics Pact are accelerating demand for mono-material aluminium packaging. Aluminium is infinitely recyclable, with Europe and North America achieving over 70% recycling rates. Brands are shifting toward plastic-free foil pouches, trays, and wraps to meet their sustainability goals. Developments in biodegradable and compostable coatings on aluminium foil are making it more sustainable. This presents a huge opportunity for companies investing in green innovations.

The foil wraps segment held a dominant presence in the aluminium foil packaging market in 2024. Foil wraps, especially aluminium foil, are widely used in packaging due to their versatility, protective properties, and sustainability. Industries such as food & beverage, pharmaceuticals, cosmetics, and industrial packaging rely on foil wraps for their barrier strength, heat resistance, and flexibility. The foil wraps are used in day to day life to prevents food oxidation, keeping snacks, dairy, and frozen goods fresh for longer.

The food & beverage segment registered its dominance over the global aluminium foil packaging market in 2024. The food and beverage industry is the largest consumer of aluminium foil packaging, driven by the need for preservation, hygiene, convenience, and sustainability. The aluminium foil packaging is lightweight and flexible, allowing easy wrapping of sandwiches, burgers, and baked goods. The aluminium foil packaging plays key role in liquid packaging. Aluminium foil in beverage cartons & cans is used in aseptic cartons (Tetra Pak) for milk, juices, and plant-based beverages. The aluminium foil packaging Maintains sterility, eliminating the need for refrigeration in shelf-stable drinks.

The 0.09 mm – 0.2 mm segment accounted for a significant share of the market in 2024. Aluminium foil with a thickness range of 0.09 mm to 0.2 mm is the most commonly used in packaging due to its optimal balance of strength, flexibility, and barrier properties. It is widely applied across food, pharmaceutical, and industrial sectors.

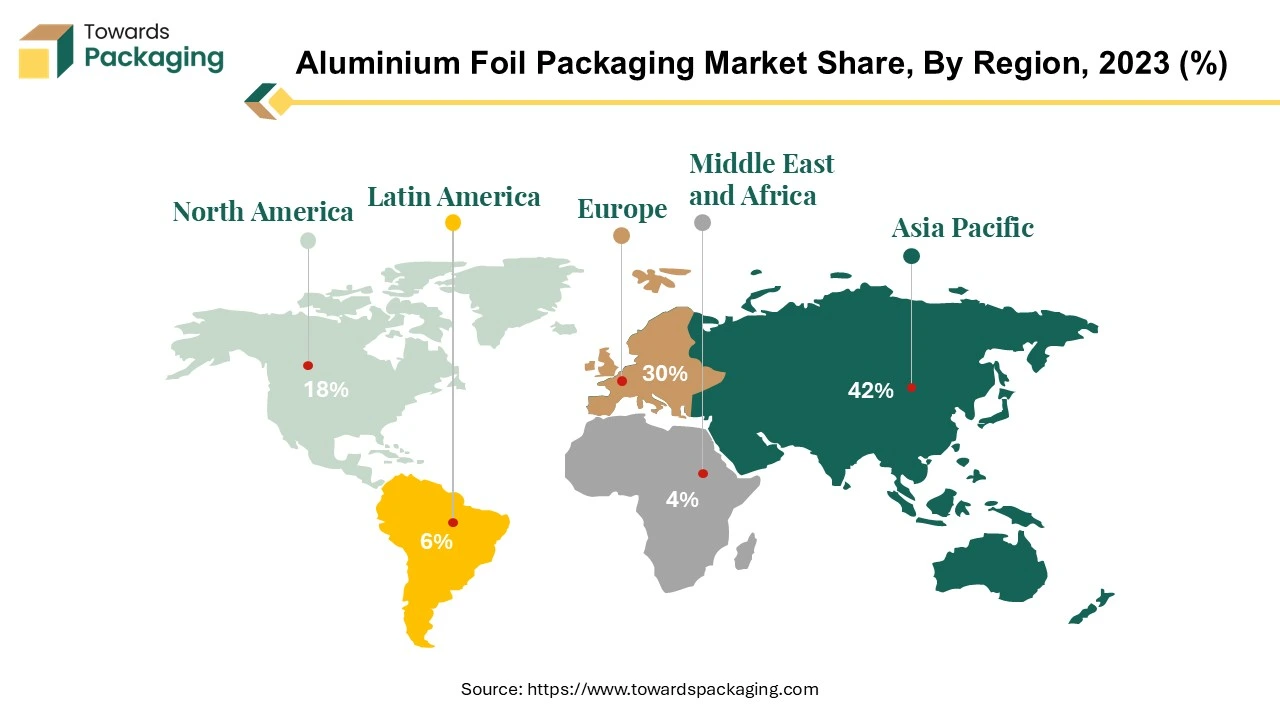

Asia Pacific region held the largest share of the aluminium foil packaging market in 2024. Rising urbanization and busy lifestyles are increasing the demand for ready-to-eat meals, snacks, and convenience foods. Countries like China, India, Indonesia, and Japan are experiencing rapid growth in online grocery shopping and meal kit deliveries. India, Japan, and South Korea are also major aluminium foil exporters, supplying global markets at competitive prices. Many Asia Pacific brands are shifting to closed-loop recycling for aluminium packaging, promoting sustainability. Japan and South Korea lead in recycling infrastructure for aluminium foil-based packaging.

India Aluminium Foil Packaging Market Trends

India aluminium foil packaging market is estimated to project large share due to large consumer base. India is the world’s largest supplier of generic medicines, increasing the demand for blister packs and pharmaceutical strip packaging. High-barrier aluminium foil protects medicines from moisture, light, and contamination. E-commerce giants like Flipkart, Amazon, and JioMart are fueling demand for foil-based protective packaging. India’s plastic ban (July 2022) is pushing companies to shift to recyclable aluminium foil packaging. Food and beverage brands are replacing plastic wraps with foil-based alternatives.

China aluminium foil packaging market has large share due to the high investment in the manufacturing of innovative aluminium packaging. China is the world’s largest producer of aluminium foil, benefiting from low-cost raw materials and large-scale manufacturing. China exports aluminium foil packaging to Europe, North America, and Southeast Asia. China’s food delivery market (led by Meituan, Ele.me, and JD.com) is booming, increasing demand for foil-based insulated packaging. China produces over 60% of the world’s aluminium, making foil packaging production cost-efficient and scalable. China has leading aluminium producers like Chalco, Hongqiao, and Zhongjin ensure a stable supply chain.

North America region is anticipated to grow at the fastest rate in the aluminium foil packaging market during the forecast period. The growth of food delivery services like Uber Eats, DoorDash, and Grubhub is increasing the need for foil-based insulated packaging. Quick-service restaurants (QSRs) such as McDonald's, Subway, and Chipotle use aluminium foil for food wrapping and takeout containers. In North America, meal kit services (HelloFresh, Blue Apron) use aluminium foil packaging for food freshness and temperature control.

U.S. Aluminium Foil Packaging Market Trends

Major U.S.-based companies like Reynolds Group, Novelis, Amcor, and Pactiv Evergreen dominate the market. The U.S. pharmaceutical industry is the world’s largest, increasing the demand for foil-based blister packs, sachets, and cold chain packaging. The U.S. EPA and state governments are enforcing strict recycling regulations. Major food brands (Coca-Cola, Nestlé, Unilever) are replacing plastic packaging with recyclable aluminium foil.

Europe region is seen to grow at a notable rate in the foreseeable future. The European Green Deal & Circular Economy Action Plan (CEAP) promote 100% recyclable and reusable packaging. The European Union Single-Use Plastics Directive (SUPD) restricts plastic packaging, increasing demand for aluminium foil as a sustainable alternative. Germany, France, and the UK lead in aluminium foil recycling programs, enhancing its market dominance. Europe is home to major aluminium packaging companies, including Amcor, Constantia Flexibles, Aluflexpack, and Eurofoil.

By Product

By End Use

By Thickness

By Region

April 2025

April 2025

March 2025

March 2025