April 2025

Principal Consultant

Reviewed By

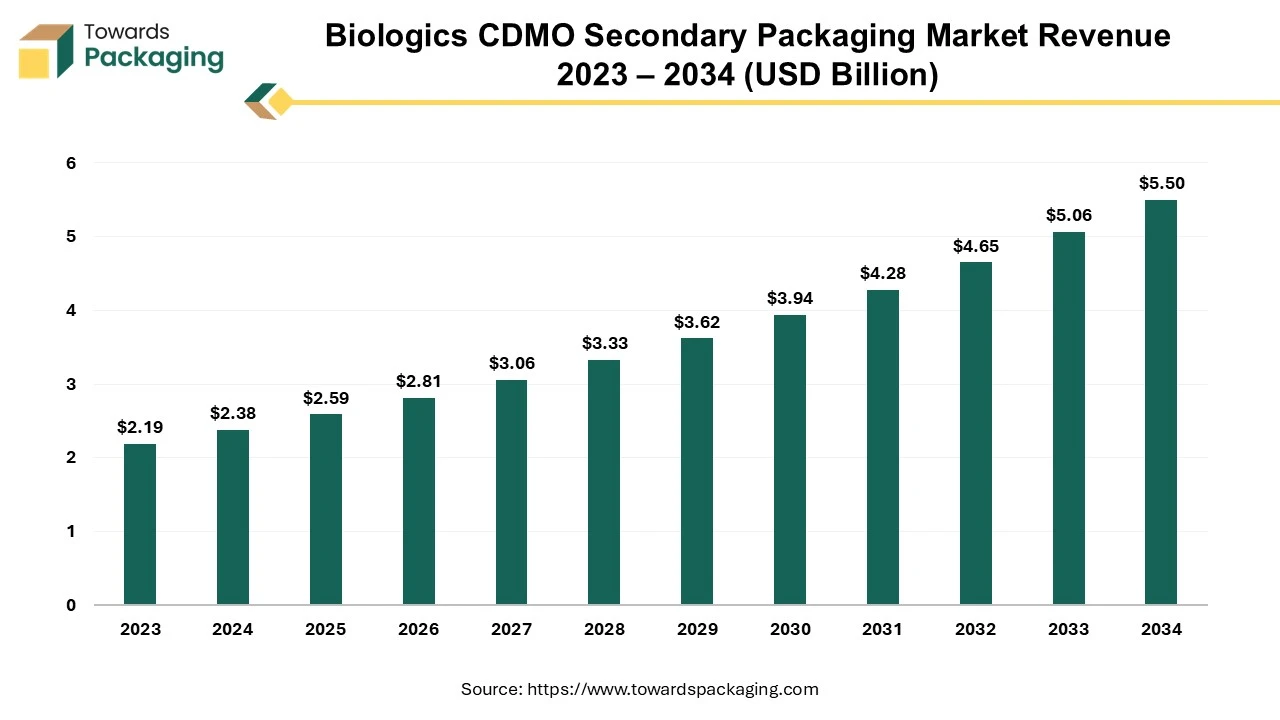

The biologics CDMO secondary packaging market is projected to reach USD 5.50 billion by 2034, expanding from USD 2.59 billion in 2025, at an annual growth rate of 8.75% during the forecast period from 2025 to 2034.

The rising market for the production of drugs is due to the increasing prevalence of chronic diseases, infectious, and genetic disorders. With the usage of such secondary packaging, there is a high chance of safety in the storage of temperature-sensitive vaccines or injectables.

The biologics CDMO secondary packaging market is developing significantly due to the expansion of the biologics industry and rising outsourcing services. Secondary packaging is important as it ensures the protection, integrity, and safety of drugs at the time of transportation and storage. These are the containers that store packaged medical products for longer-distance transportation during the distribution of the products.

This sector such as cartonization, labelling, and other things done after the primary packaging of syringes, vaccine bottles, and various others. The market is growing rapidly due to increasing medical facilities like biological therapies which include gene therapy, biosimilars, and monoclonal antibodies. Major market players such as WuXi Biologics (Cayman) Inc., FUJIFILM Diosynth Biotechnologies U.S.A. Inc., Samsung Biologics Co. Ltd., Thermo Fisher Scientific Inc., Rentschler Biopharma SE, and others are introducing innovation in this field continuously.

The growing collaboration between companies contributes to the development of the biologics contract development and manufacturing organization (CDMO) secondary packaging market. Customers seeking good storage and risk-free transportation of pharmacy products for longer shelf life compel companies to collaborate to bring innovation to the market. Secondary packaging is the outer labelling and packaging of the biological products which plays a vital role in safeguarding medical products to maintain the optimum temperature required. The need for cold chain supervision in biological product carriage enhances the intricacy of secondary packaging, boosting companies to accept advanced and dedicated packaging materials and skills. The growing speed of developments in biopharmaceutical production, for the formation of biologics that can improve healthcare, is influencing the market.

The development of the biologics industry, along with delicate regulatory pressures, is influencing the demand for more effectual, complaint, and cost-operative secondary packaging results. This movement is generating noteworthy openings for CDMOs to improve their facility contributions, enlarge their competencies, and enhance the growing demands of the biologics sectors, boosting the development of the biologics CMDO secondary packaging market.

The biopharmaceutical sector is growing rapidly due to the innovation by drug companies, mainly vaccines for rising diseases and changing lifestyles. In this business it is anticipated to present several new products, such as handling for diseases, to fulfil significant demand for medical challenges. The biologics CDMO market is rising speedily, as pharmaceutical and biotech market players progressively outsource the growth and industry of biological drugs to CDMOs. CDMOs deliver proficiency, machinery, and cost-operative solutions to fulfil the rising demand for medical products. Furthermore, the rising speed of developments in the biopharmaceutical business, for the formation of biologics which can improve healthcare, is boosting the market.

North America witnessed the largest revenue share for the year 2024 this growth is due to the rapid rise of manufacturing of pharmaceutical products which is due to the rising healthcare infrastructure and demand from the experts. In various countries such as the U.S. and Canada, there is an upsurge in the demand for biological products due to chronic diseases such as diabetes and various infectious diseases. The rising concern for the safe storage of healthcare products for better and long-term usage of drugs such as secondary packaging is highly preferred by companies. The presence of strong market players and the advanced healthcare sector raise the demand for biological products that influence the packaging market.

Asia Pacific is estimated to grow at the fastest rate over the forecast period. Continuous investment of government bodies towards healthcare sector to introduce advanced technology with the rising number of diseases. With more funding production increases in pharmaceutical companies which increases the demand for storage of the medicines.

Countries like China, Japan, India, Thailand, and South Korea are observing advancement in the healthcare sector due to the investment of the government in this industry. The region is producing cost-effective packaging options for medicinal products like syringes, drugs, and various other products. These packaging companies adopt advanced technology for temperature regulatory sealing of the containers.

By Product Type

By Primary Package Type

By Region

April 2025

April 2025

March 2025

March 2025