April 2025

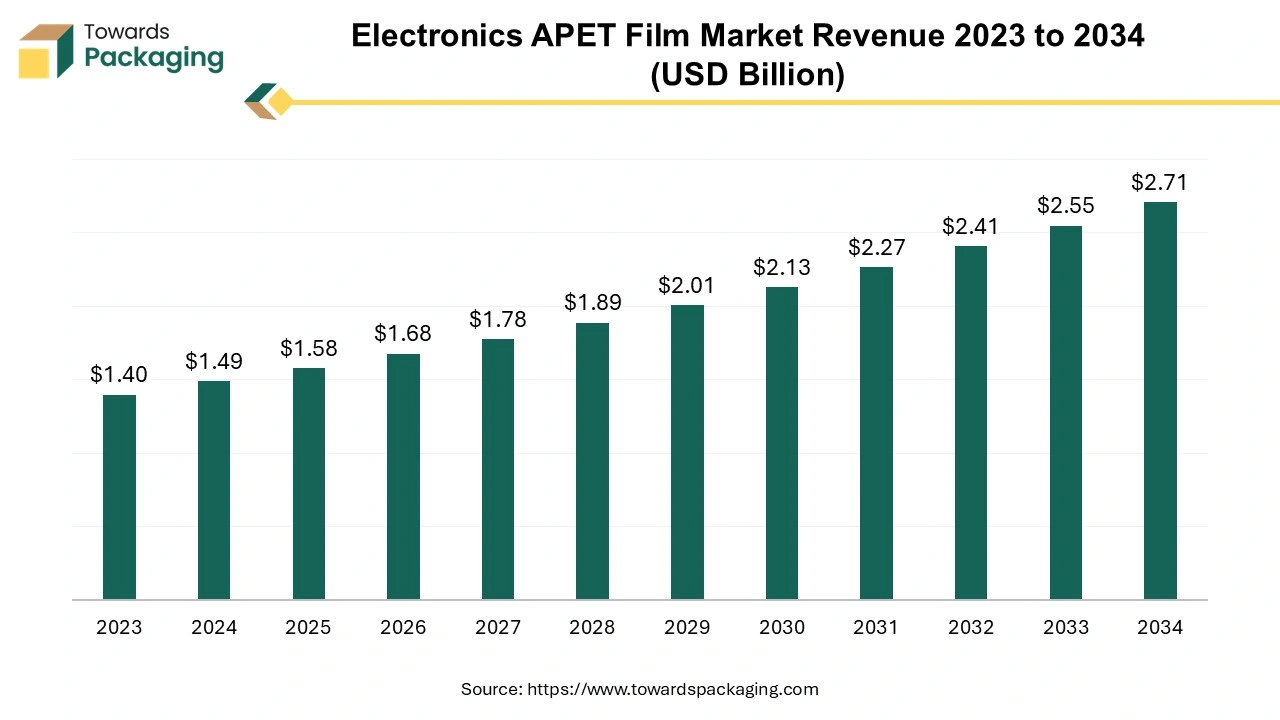

The electronics APET film market is expected to increase from USD 1.58 billion in 2025 to USD 2.71 billion by 2034, growing at a CAGR of 6.2% throughout the forecast period from 2025 to 2034.

The market is proliferating due to the increasing electronics and electrical business where there is a need for semiconductor devices and various electrical parts like circuit boards, semiconductors, and many others for different purposes. The rising usage of electrical devices in all sectors influences the demand for electronics APET film.

APET film is the rigid polyester film or rigid PET film that is widely spreading rapidly as a packaging material because of its excellent ease, super strength, and clarity of handing out. Moreover, polyester material is used as an environment-friendly substitute for plastic materials such as PVC film. The electronics APET film market plays an important role in electronics, confirming that circuit boards and semiconductors are packed efficiently in several applications. The global packaging industry size is growing at a 3.16% CAGR.

The continuous rise of the need for ecologically friendly and biodegradable packaging in all industries. It is also due to its thermal stability, recyclability, and clearness of electronics APET film that enables producers to diminish their ecological impression. The growing food & beverage market mixed with customers who are concerned with clean, clear packaging enhances the demand for electronics APET film. There are several other features, such as the numerous industrial claims of this substance from electronics to automotive, because of its electrically insulating properties. All these factors boost the inclusive development of the international electronics APET film market to grow.

There is a rising trend in the demand for sustainable packaging of electronic products influenced by growing innovative sustainable solutions and compliance with ecological guidelines.

The growing acceptance variety of electronic products that need proper packaging methods for safety purpose of the products. APET films work as safe layers for large display screens.

Due to the growing urbanization and industrialization developing economies are influencing market development, as demand for electronic products such as in industries, offices, residents, and various other places growing also drives the packaging solutions.

Continuous advancements in the technology of the packaging process of integrated circuits such as system-in-packaging (SiP), 3D packaging, and fan-out wafer-level (FOWL) packaging.

There are several opportunities to flourish in the electronics APET film market, majorly with the advancements in technology. Revolutions in the existing techniques and surface handling skills are set to boost the presentation nature of electronics APET films which are making them appropriate for specific demand in industries such as renewable energy and the automotive market. Furthermore, the development of the e-commerce industry demands strong packaging solutions that uphold product integrity, placing electronics APET films as a preferable choice for both consumers and manufacturers.

As market players continue to arrange sustainability, the expansion of bio-based electronics APET substitutes offers a promising limit, positioning with international efforts to decrease environmental impact. The electronics APET film market is composed of noteworthy development, determined by a combination of invention, developing requests, and altering customer choices, confirming it as a crucial sector in the worldwide economy.

Changing charges also make it problematic to preserve both cost-efficiency and steady profit borders. But additional restraint is connected to the precise regulatory scenery. Strict environmental guidelines and values with admiration to plastic packaging materials need compliance actions, which will disturb production procedures or even boundary some applications of electronics APET film.

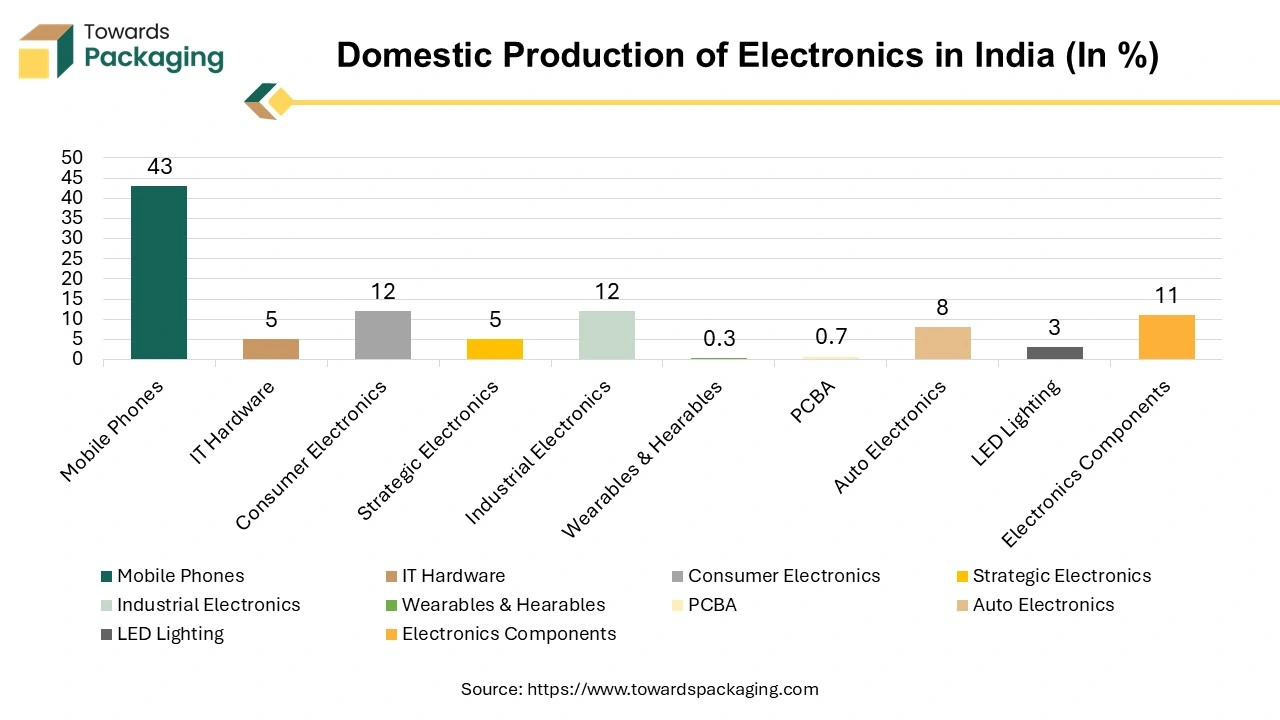

Asia Pacific witnessed the highest revenue share for the year 2024 this growth is because of its favorable and versatile quality. It is extensively used by several consumer electronics, automotive components, and packaging applications. The growing electronics industry in various countries such as Japan, India, China, Thailand, and South Korea resulted in rising demand for electronics APET film market.

There is a huge demand for superior quality performance in electrical items such as display screens with high quality and many more. These films are highly resistant to heat and are lightweight, making them perfect for various packaging services. With the rising concern for environmental issues, there is a huge shift towards the demand for sustainable packaging films. These films are highly recyclable and also require less energy for their manufacturing in comparison with other plastics available in the market. Strict rules of the government for the usage of plastic packaging also influence the electronics APET film market. In this region, there is a rapid increase in infrastructure construction that results in rising demand for high-quality electronics items such as large screens, lights, AC, and various other products resulting in the growing demand for good quality packaging that can protect products from minor damage like scratches to breakage of the item.

North America is estimated to grow at the fastest rate over the forecast period. Several brand holders and producers in the United States are remaining to announce new packaging plans to enhance sustainability and solve consumer issues. The rising demand for electronic packaging in the advanced electronics and telecommunication market attached to the noteworthy electronics transportation from countries like the US and Canada is anticipated to influence the market development. With this rapid change in the current trend of electronics APET films is growing in the market in the United States.

With the fast growth of supervisory pressure and superior quality recyclable materials, packaging market players prefer to use electronics APET films because of their exceptional barrier nature. Producers in various countries are fast-tracking their way to influence packaging commitments by evaluating customs to expand packaging strategy to confirm the material is improved from the excess streams. This provides opportunities for new startup companies as well as established companies in the market. These films are dropping the growth of carbon footprints and are also manufactured intending to reduce plastic waste. With the adoption of APET film for packaging purposes brands are enhancing their appeal and image in the market. As customers become more worried about sustainable packaging solutions and materials so there is an increase in the demand for electronics APET in this region. Eco-friendly products are developing rapidly in the electronics APET film market, mainly for packaging purposes.

By type, the anti-fog APET film segment led the electronics APET film market in 2024. Anti-fog APET film is widely used to avoid the damage caused due to moisture on the packaging of food products to avoid contamination or spoiling. These anti-fog layered APET films are free from any toxic substances. FDA-approved films can be applied to toys, food, cosmetics, electronic products, and various other products that require anti-fogging visual packaging. Anti-fog-treated APET film is suitable for food packaging to protect against food from fogging on the inside of the surface. Water content is available in food which causes condensation on the surface of the packaging that can cause damage.

By application, the blister packaging APET film segment led the electronics APET film market in 2024. It is considered a suitable packaging type to protect all electronic products. It provides top-quality safety to the products from dust, moisture, or any physical damage. These are generally used in packaging connectors, circuit boards, and various such devices. As these can be recycled easily and several times they are considered to be the best fit for blister packaging which aligns with the ecological goals. As industries are seeking aesthetics and functionality, this segment of blister packaging is contributing to significant growth in this market.

By Type

By Application

By Region

April 2025

April 2025

February 2025

February 2025