April 2025

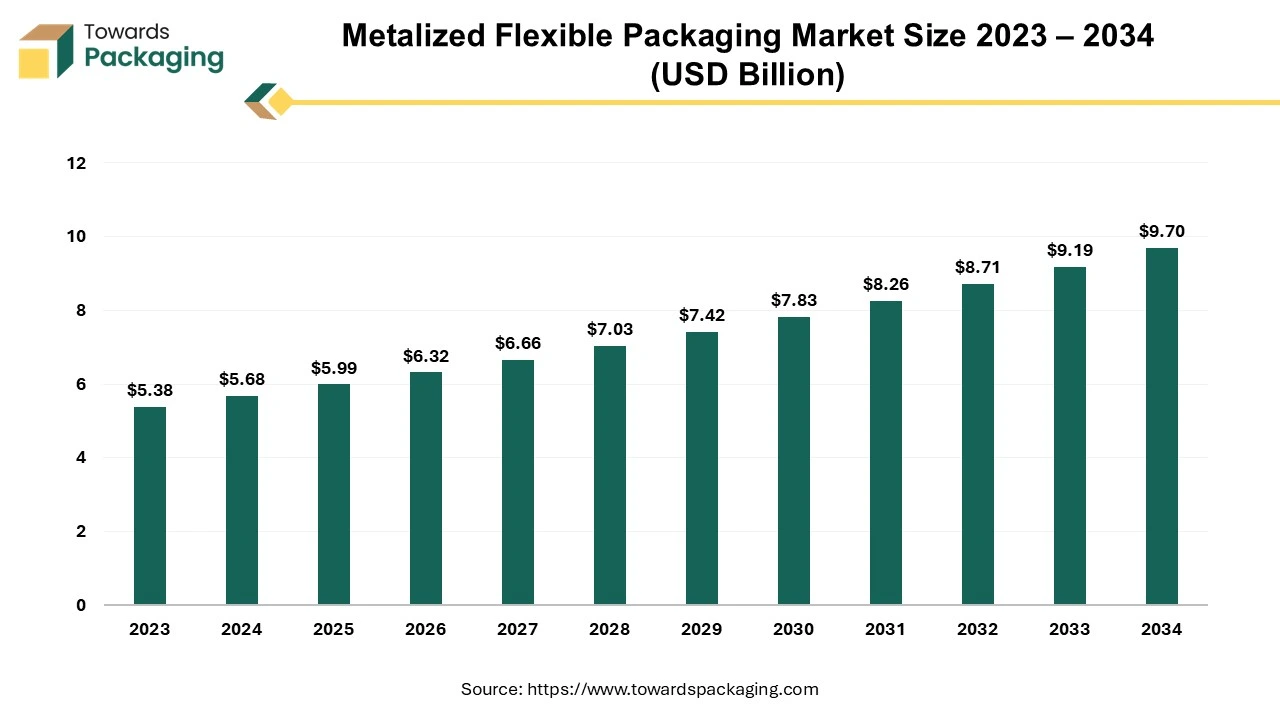

The global metalized flexible packaging market size reached US$ 15.30 billion in 2025 and is projected to hit around US$ 22.76 billion by 2034, expanding at a CAGR of 4.55% during the forecast period from 2025 to 2034.

Metalized flexible packaging typically comprises a metal-coated polymer film, with aluminium being the most commonly used metal. However, chromium and nickel are also employed in this process. These films are generally produced by heating metals in a vacuum, leading to the condensation of metal droplets on polymer films and the formation of metalized films. Like aluminium foils, metalized flexible films exhibit a shiny metallic surface and are highly combustible. However, they are lighter and more cost-effective due to their significantly thinner profile than aluminium foils. The industry's widespread adoption of flexible packaging and films is attributed to various technological advancements.

The advantages of flexible packaging and films are further enhanced when considering different coatings, film types, and production methods. Both materials inherently offer excellent barrier capabilities. While seed packages were once simple containers, contemporary packaging, as outlined by the United States Department of Agriculture (USDA), involves various processes and materials to preserve the original quality of seeds between their preparation and planting. Moisture absorption is not a concern when storing dry seeds in moisture-resistant containers. Under various temperature and humidity conditions, dehydrated seeds in moisture-proof containers maintain good viability and vigor.

The global packaging landscape has witnessed a significant evolution in recent years, around US$ 500 Billion, with innovative materials playing a pivotal role in enhancing product protection, shelf appeal, and sustainability. By 2025, the market value of the global flexible packaging industry is expected to reach USD 278.9 billion. The flexible packaging market is anticipated to be driven by consumer demand for customer-friendly packaging and increased product protection. Growth and expansion in the industry are being propelled by e-commerce, digital printing, and sustainability. Food is the primary application for flexible packaging, accounting for over 60% of the market. One such notable advancement is the advent of metalized flexible packaging.

Metalized flexible packaging comprises a blend of high-quality flexible films—such as polyethene, polypropylene, and polyester—strengthened by a thin metalized layer, typically aluminium. The metallization process creates a protective barrier that shields packaged goods from external elements, including moisture, light, and oxygen. An adhesive layer ensures the steadfast bonding of the metalized layer to the flexible film, and additional printing and lamination processes allow for customization, branding, and enhanced durability.

The incorporation of a metalized layer offers a myriad of benefits to both manufacturers and consumers. The barrier properties of the metal layer safeguard products against environmental factors, extending shelf life and maintaining freshness. The metalized surface's reflective nature protects against harmful UV rays, making it an ideal choice for light-sensitive products. Furthermore, the thermal insulation properties contribute to the preservation of temperature-sensitive items.

Metalized flexible packaging has versatile applications across various industries, including food and beverages, pharmaceuticals, cosmetics, and more. From snacks and coffee to pharmaceuticals and personal care products, this innovative packaging solution caters to the diverse needs of manufacturers aiming to deliver high-quality, protected, and visually appealing products to consumers. The metalized flexible packaging market has witnessed robust growth, driven by the increasing demand for packaging solutions that marry functionality with aesthetics.

| Trends | |

| Sustainable Packaging Solutions | As sustainability becomes a paramount concern across industries, the metalized flexible packaging market is witnessing a surge in demand for eco-friendly solutions. Manufacturers are increasingly exploring recyclable and compostable materials to align with consumer preferences for environmentally conscious packaging. |

| Customization and Branding | The importance of brand identity and consumer engagement has led to a growing customization trend in metalized flexible packaging. Advanced printing technologies allow for intricate designs, vibrant colours, and unique branding, enhancing the visual appeal of products on the shelf and creating a more memorable consumer experience. |

| Focus on Extended Shelf Life | One of the primary advantages of metalized flexible packaging is its ability to extend the shelf life of packaged products by providing a robust barrier against moisture, oxygen, and light. This trend is particularly notable in the food and pharmaceutical industries, where preserving product freshness is critical. |

| Technological Advancements in Manufacturing Processes | Continuous advancements in manufacturing technologies are influencing the metalized flexible packaging market. From improved metallization processes to innovations in printing and lamination techniques, these technological developments enhance the overall quality, efficiency, and cost-effectiveness of metalized packaging. |

| Growing Emphasis on Convenience Features | Consumer lifestyles are increasingly fast-paced, leading to a demand for convenient packaging solutions. Metalized flexible packaging is adapting to this trend with features such as resealable closures, easy-open designs, and portion-controlled packaging, catering to the evolving needs of modern consumers. |

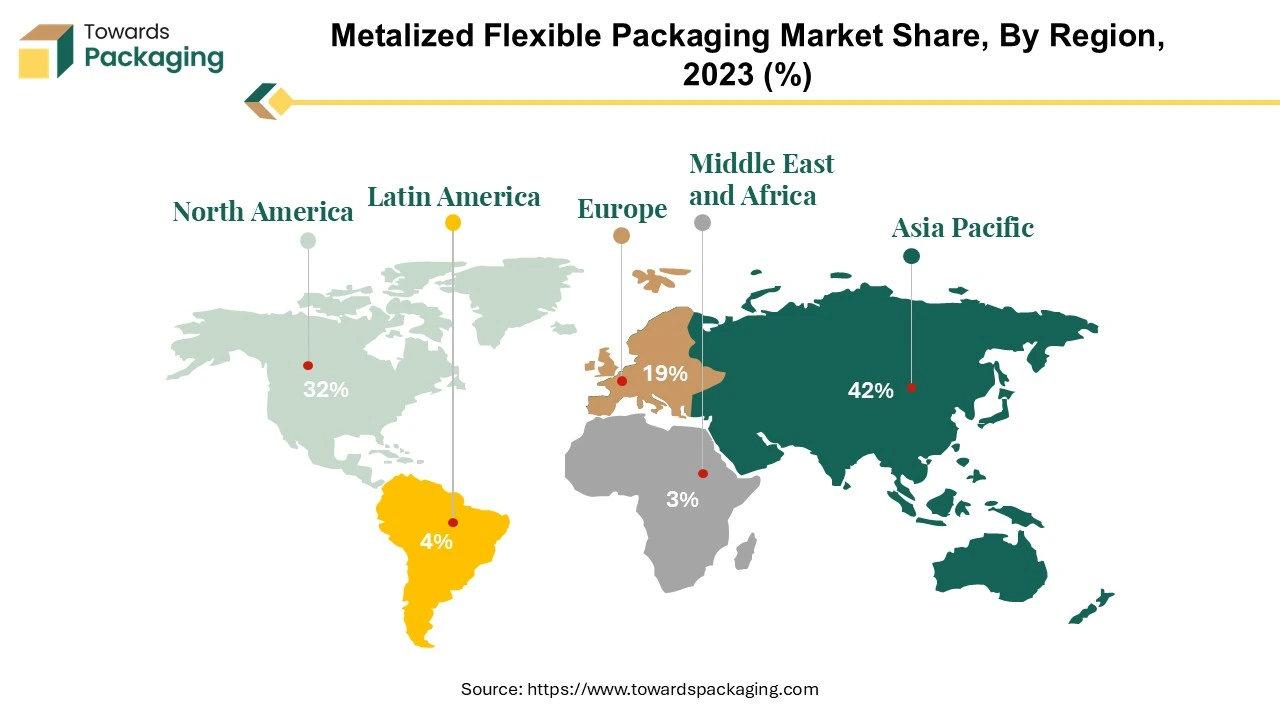

The Asia Pacific region has firmly established itself as a dominant force within the global metalized flexible packaging market, securing a regional leadership position, accounting for 42% of flexible packaging. This ascendancy is propelled by the robust growth of industries, with key countries such as China, India, and Japan spearheading advancements. The region's escalating demand for packaging solutions that seamlessly blend convenience with visual appeal aligns harmoniously with the capabilities inherent in metalized flexible packaging, thereby driving its widespread adoption.

At the heart of Asia Pacific's leadership is its manufacturing prowess, an industrial powerhouse fostering innovation and production efficiency. This manufacturing excellence and a commitment to continuous technological advancements position the region as a hotbed for cutting-edge developments in metalized flexible packaging. The result is a landscape that not only meets but anticipates market trends, showcasing a keen responsiveness to the dynamic needs of industries and consumers alike.

Moreover, Asia Pacific's strategic influence is evident in its role as a critical influencer shaping the trajectory of the metalized packaging landscape globally. The region's dynamic market presence contributes significantly to the evolution and expansion of the metalized flexible packaging market on an international scale. Its proactive approach to adopting emerging technologies and a deep understanding of market trends and preferences solidify its standing as a driving force behind the continuous innovation within the metalized packaging sector.

Asia Pacific's regional leadership in the metalized flexible packaging market results from its thriving industries, commitment to technological advancement, and proactive stance in shaping industry trends. As the region continues to play a pivotal role in global economic dynamics, its influence on the evolution of metalized packaging remains a compelling narrative within the broader context of the packaging industry.

North America is a critical player in the global metalized flexible packaging market, standing shoulder to shoulder with the dominant Asia Pacific region. The region's influence is deeply rooted in a well-established packaging industry known for its commitment to technological innovations and a growing emphasis on sustainable solutions.

The strength of North America's influence lies in its robust and mature packaging sector, which continuously drives advancements in technology and practices. This commitment to innovation has propelled the adoption of metalized flexible packaging as a strategic response to the evolving needs of both manufacturers and discerning consumers. In particular, strongholds in the food and beverage, pharmaceutical, and healthcare sectors contribute significantly to the demand for advanced packaging solutions.

Furthermore, North America's proactive stance towards sustainable practices is evident in its emphasis on eco-friendly packaging solutions. Metalized flexible packaging, with its ability to balance functionality and environmental considerations, aligns seamlessly with this trend. The region's pursuit of sustainable practices extends to its commitment to regulatory compliance and adherence to international quality standards. This proactive approach ensures the safety and reliability of packaged products and underscores North America's commitment to industry-wide best practices.

North America's strategic position as a market player reflects its industrial capabilities, technological prowess, and proactive approach to industry trends. As a result, the region contributes significantly to shaping the trajectory of the global metalized flexible packaging landscape. Its influence extends beyond its borders, serving as a benchmark for best practices and driving continuous innovation in the ever-evolving field of flexible packaging. North America's dynamic and influential role reinforces its standing as a critical player in the global metalized flexible packaging market.

Metalized films play a pivotal role as a foundational element. These films are meticulously crafted from flexible materials, including polyethene, polypropylene, or polyester, and are fortified with a delicate yet robust layer of metal, typically aluminium. This process, known as metallization, imparts the resulting film with a formidable protective barrier, effectively creating a shield against external elements such as moisture, oxygen, and light. The distinctive protective attributes of metalized films position them as the material of choice across various industries.

Demand for flexible films is anticipated to be between 13 to 15 Mt across all polymers, with 2 to 2.5 Mt needed for PP and multi-material multilayer flexible films, respectively. Their ability to seamlessly integrate durability, adaptability, and essential barrier properties is a crucial driver of their widespread adoption. This versatility places metalized films at the forefront of innovation within the expansive domain of flexible packaging, catalyzing advancements that directly address the evolving needs of both manufacturers and consumers.

The synergy of flexible materials with the metallized layer not only enhances the physical properties of the film but also contributes significantly to the longevity and preservation of packaged contents. This is particularly critical in industries where product integrity and shelf life extension are paramount considerations. The application of metalized films extends across various sectors, from food and beverages to pharmaceuticals, showcasing their adaptability and effectiveness in meeting diverse packaging requirements. As the market continues to demand packaging solutions that balance functionality with sustainability, metalized films stand out as a cornerstone technology, ensuring products remain protected and visually appealing in the ever-evolving landscape of flexible Packaging.

Metalized pouches represent a pinnacle of innovation within the metalized flexible packaging market, seamlessly blending functionality with visual appeal. These pouches leverage the advantages inherent in metalized films, integrating a robust barrier against external elements while embodying the flexibility and convenience associated with pouch formats. By incorporating metalized layers, these pouches create a reliable shield against moisture, oxygen, and light, positioning them as an ideal packaging solution for diverse products with a significant presence in the dynamic food and beverage sector.

The rising prominence of metalized pouches can be attributed to their ability to extend the freshness of packaged products and address environmental considerations through a lightweight design. As sustainability becomes a central focus, the eco-friendly nature of metalized pouches aligns with consumer preferences for environmentally conscious packaging solutions. Beyond their functional attributes, metalized pouches stand out for their adaptability to intricate designs and branding. This feature enhances product visibility on shelves and contributes to a positive and memorable consumer experience.

Metalized pouches exemplify a harmonious union of form and function in contemporary packaging solutions. Their versatility and ability to provide adequate product protection and cater to evolving consumer expectations position metalized pouches as a sought-after and innovative choice in the ever-evolving landscape of metalized flexible packaging.

In food and beverage packaging, metalized flexible packaging emerges as a pivotal player, addressing the critical imperative of preserving product quality and freshness. Deployed in the form of both films and pouches, metalized packaging significantly extends the shelf life of perishable items, ranging from snacks and coffee to ready-to-eat meals. The reflective properties of the metalized layer add an extra layer of protection by mitigating the impact of harmful UV rays, ensuring the integrity of sensitive contents. Beyond its protective functions, the lightweight and customizable nature of metalized packaging offers brands a platform to differentiate themselves on store shelves. This not only enhances brand visibility but also fosters heightened consumer engagement. Thus, metalized flexible packaging stands as a cornerstone in the ever-evolving landscape of food and beverage packaging, addressing both functional and aesthetic considerations.

The metalized flexible packaging Market is characterized by intense competition because there are several key players, such as Amcor PLC, Sonoco Products, Mondi PLC, Cosmo Films, Uflex Limited, Huhtamaki Oyj, Sealed Air Corporation, Polyplex Corporation and others. This market has a medium level of market concentration, and several major players are present, using tactics such as product innovation, mergers and acquisitions to obtain a competitive edge. The market players are significantly impacting environmental development by adopting sustainable packaging and creating awareness among consumers through innovative packaging materials. Lead players Amcor PLC and Mondi PLC have a global impact by lowering carbon emissions through cutting-edge packaging materials used by industry leaders who pioneered sustainable packaging by introducing metalized flexible packaging in their packaging and other materials for the food and beverage, personal care, and pharmaceutical industries.

By Material

By Type

By End Use

By Region

April 2025

April 2025

April 2025

April 2025