April 2025

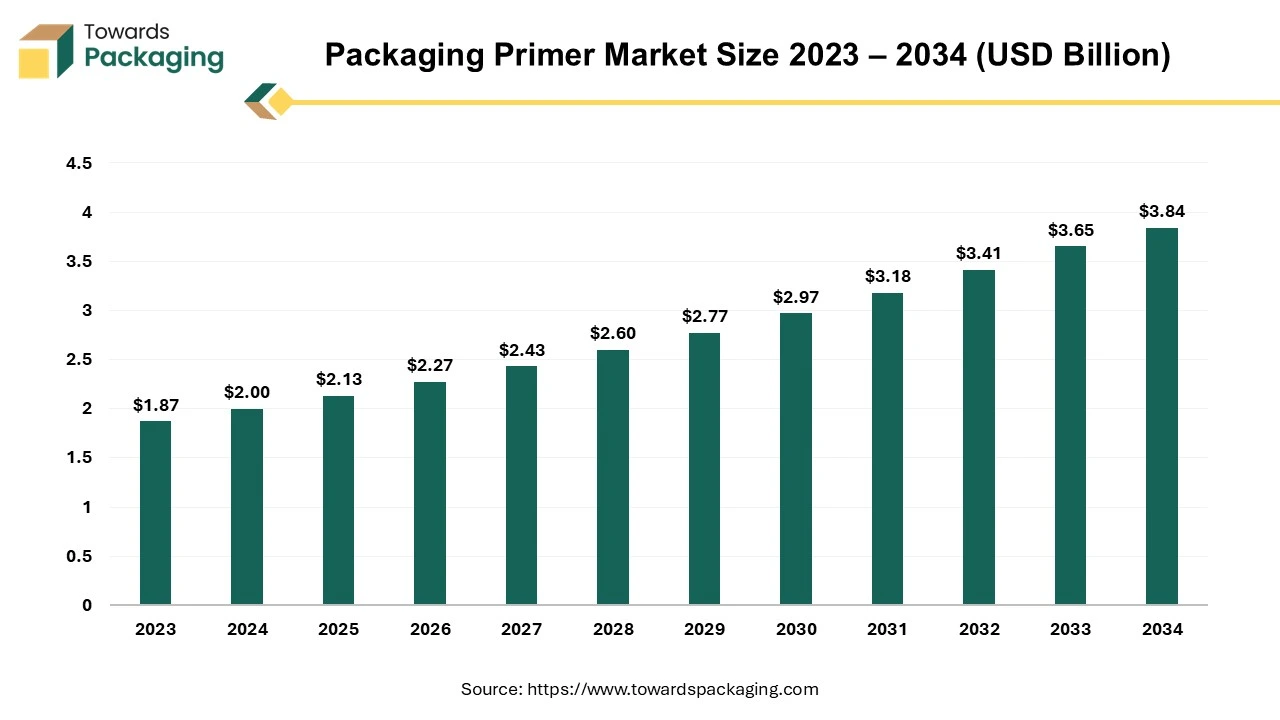

The global packaging primer market size reached US$ 2 billion in 2024 and is projected to hit around US$ 3.84 billion by 2034, expanding at a CAGR of 6.75% during the forecast period from 2025 to 2034. A key factor driving this growth is the increasing focus of leading market players on inorganic growth strategies, such as mergers and acquisitions. These strategic moves are enabling companies to develop advanced technologies for manufacturing high-performance packaging primers, which is expected to further propel the market forward over the forecast period.

Unlock Infinite Advantages: Subscribe to Annual Membership

A packaging primer is a preparatory or foundational coating applied to packaging materials before printing, coating, or adhesive applications. It serves multiple functions, including improving printability, enhancing adhesion, and offering a protective barrier. A packaging primer is a crucial component in the packaging industry, ensuring durability, print quality, and protection. The choice of primer depends on the material, printing method, and application needs. With the increasing focus on sustainability, the development of eco-friendly primers is shaping the future of packaging solutions.

Rising demand for primers that minimize environmental impact. Manufacturers are developing water-based and low-VOC (Volatile Organic Compound) primers to meet stringent environmental regulations and cater to eco-conscious consumers. For instance, companies like PPG Industries are focusing on creating water-based primers with reduced VOC emissions, aligning with global sustainability goals.

Industries such as food, pharmaceuticals, and cosmetics are increasingly utilizing specialty primers that offer enhanced barrier properties, moisture resistance, and chemical protection. These primers ensure product integrity and extend shelf life, addressing specific packaging requirements.

The industry is witnessing innovations like UV-curable and fast-drying primers, which support high-speed printing and improve production efficiency. These advancements cater to the need for rapid turnaround times in packaging processes.

Brands are adopting unconventional packaging designs, known as 'chaos packaging,' to capture consumer attention. This trend involves using unexpected packaging formats to create a memorable consumer experience, thereby enhancing brand recognition and appeal.

AI-powered predictive modeling can help develop new primer formulations by analyzing chemical interactions and performance outcomes. Machine learning algorithms can recommend eco-friendly alternatives to traditional solvents and chemicals. AI-driven material science can optimize primer properties like adhesion, flexibility, and drying speed, improving performance. AI-powered computer vision systems can detect defects such as uneven coating, air bubbles, or improper adhesion in real time.

AI-driven robotic systems can precisely apply primers, ensuring uniform coating and minimal material waste. Smart sensors and AI algorithms can monitor and adjust primer application in real time for optimal efficiency. Automated self-adjusting production lines can optimize throughput while reducing human error.

AI-powered supply chain analytics can minimize overuse of raw materials, reducing environmental impact. Predictive maintenance using AI can prevent machine breakdowns, reducing downtime and waste. AI-driven lifecycle analysis can help brands develop recyclable and biodegradable primer solutions. AI can enable adaptive primers that respond to environmental conditions, improving durability and shelf life. Machine learning can tailor primer properties based on specific product needs (e.g., temperature resistance for frozen foods, chemical resistance for pharmaceuticals).

AI can also enhance digital printing on primers for customized branding and interactive packaging. AI can automate compliance tracking, ensuring packaging primers meet environmental and safety regulations across different markets. AI-driven chemical analysis tools can predict potential hazards or interactions, preventing health risks.

The e-commerce boom has increased the need for durable and visually appealing packaging, boosting the demand for advanced primers. Growth in digital printing requires primers that enhance print adhesion and color vibrancy, improving branding and customization. By 2026, social commerce will be valued at US$2.9 trillion. That represents a staggering 30.81% rise over the prior year. According to E-commerce Professionals Association (ePA), the social commerce industry is expected to reach US$8.5 trillion by the end of the projection period, growing at a compound annual growth rate (CAGR) of 29% between 2022 and 2030.

The key players operating in the market are facing issue due to strict regulatory norms and slower growth in emerging market which has estimated to restrict the growth of the packaging primer market in the near future. Regulatory restrictions on VOC emissions in solvent-based primers limit their use, pushing manufacturers to invest in expensive eco-friendly alternatives. Compliance with FDA, EU, and REACH regulations for food and pharmaceutical packaging increases R&D costs and slows product launches. In developing regions, limited awareness and low investment in advanced packaging solutions slow the demand for high-performance primers. Cost-sensitive industries in emerging economies often opt for cheaper, lower-quality alternatives instead of premium primers. Differences in regional regulations and industry requirements create challenges in developing universal primer formulations. Customization needs increase production complexity and slow mass adoption.

Regulatory pressures and consumer demand for sustainable packaging are pushing companies to use low-VOC, water-based, and biodegradable primers. Governments worldwide are enforcing strict environmental regulations, driving innovation in eco-friendly primer formulations. Increasing innovation and launch of the sustainable packaging has estimated to create lucrative opportunity for the growth of the global packaging primer market in the near future.

The shift from rigid to flexible packaging (e.g., pouches, wraps) has increased demand for primers that improve adhesion on plastic films and laminates. Lightweight packaging materials require special primers to maintain print quality and barrier properties. Increasing launch in flexible packaging and lightweight materials has created lucrative opportunity for growth of the global packaging primer market over the forecast period.

The solvent-based coatings segment held a dominant presence in the global packaging primer market in 2024. The solvent-based primers evaporate quickly, allowing for faster processing speeds in high-volume packaging production. They provide excellent adhesion to various substrates, including plastics, metals, and flexible films, ensuring durability. These coatings offer strong resistance to moisture, chemicals, and temperature variations, making them ideal for food and pharmaceutical packaging. Solvent-based coatings layer that enhances the appearance and functionality of the packaging.

The aluminium makers segment accounted for a significant share of the global packaging primer market in 2024. Aluminium offers protection against moisture, oxygen, UV light and contaminants, making it ideal for food, beverage, and pharmaceutical packaging. Aluminum has high adhesion and compatibility which an ideal primer requires. Aluminium is highly recyclable, aligning with global sustainability trends. Many brands prefer aluminium-based packaging for eco-friendly initiatives.

Asia Pacific held the largest share of the market in 2024 and is anticipated to grow at the fastest rate in the packaging primer market during the forecast period. Increasing urban populations and expanding industrial sectors are driving higher demand for advanced packaging solutions. The surge in online shopping, especially in countries like China, India and Southeast Asia, is driving the need for durable, protective, and printable packaging materials. The well-established Pharmaceutical and Biotechnology industries in Asia Pacific region especially India and China has driven the growth of the global packaging primer market in the near future.

North America is observed to grow at the fastest rate during the forecast period. North America region has well-established packaging sector, driven by industries like food & beverage, pharmaceuticals, and personal care, all of which require high-quality primers. North America is home to leading packaging and coating companies some of which have been here as followsMichelam, PPG Industeries, Inc., The Sherwin-Williams Company, Axalta Coating Systems, LLC, and AkzoNobel N.V. among others. The presence of leading companies in North America that invest in Research and Development (R&D) for innovative primer formulations, including eco-friendly and high-performance solutions promote the dominance of region in global packaging primer market.

By Primer

By Application

By Region

April 2025

April 2025

April 2025

April 2025