May 2025

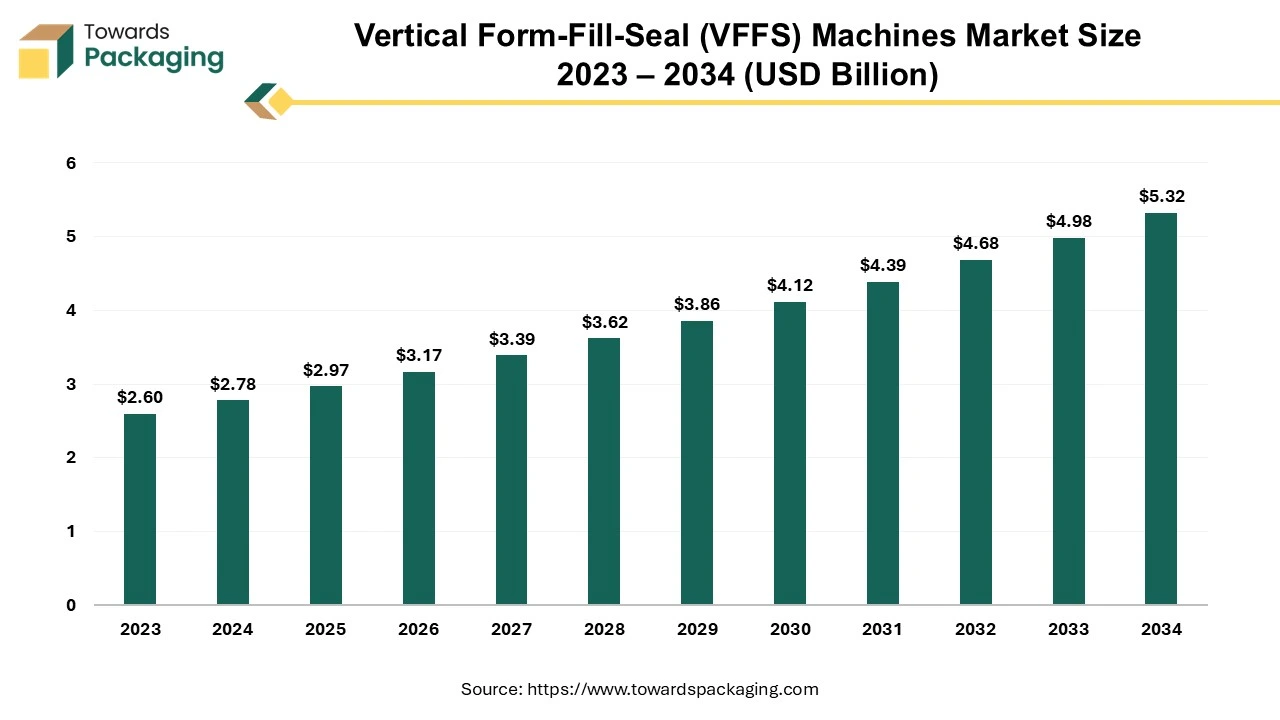

The global vertical form-fill-seal (VFFS) machines market size reached US$ 2.78 billion in 2024 and is projected to hit around US$ 5.32 billion by 2034, expanding at a CAGR of 6.75% during the forecast period from 2025 to 2034. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing vertical form-fill-seal (VFFS) machines has estimated to drive the global vertical form-fill-seal (VFFS) machines market over the forecast period.

Vertical form fill seal (VFFS) machines are automated packaging machines that fill, form, and seal flexible pouches or bags in a vertical orientation. They are commonly used in food, pharmaceuticals, and consumer goods industries for efficient, high-speed packaging. The vertical form-fill-seal (VFFS) machines works by film unwinding, bag formation, vertical sealing, product filling, and horizontal sealing & cutting. The advantages of vertical form-fill-seal (VFFS) machines are high-speed & continuous operation, versatile packaging, cost-effective, and compact design.

Automation in vertical form-fill-seal machines has enhanced the production accuracy and reduced the labor cost. The one the key reason behind the popularity of these machines is that this machines has proved its ability to provide exceptional protection against oxygen, moisture and UV light which making it the best solution for the packaging industry. Moreover, the integration with Industry 4.0 technologies such as IoT has enabled the real-time monitoring, predictive maintenance and high production efficiency has completely changed the traditional manufacturing units while boosting the production quality and reduced labor cost.

Moreover, the Industry 4.0 technology has enabled better monitoring and automated defect detection features with the IoT integration, which has made the machine highly advanced and efficient. This will defiantly able to cater to the growing demand for effective packaging solutions. The increasing population, with the availability of disposable income is driving the demand for packaged food items, beverages, pharmaceuticals, and personal care products.

Because of these conditions, the market is offering various investment opportunities to the stakeholders across the globe. Due to the increasing demand for the efficient and high speed packaging manufacturers are moving towards the vertical form fill seal machines. The market is highly demanding features like multilane packaging, customized packaging designs and eco-friendly solutions.

| Metric | Details |

| Market Size in 2024 | USD 2.78 Billion |

| Projected Market Size in 2034 | US$ 5.32 Billion |

| CAGR (2025 - 2034) | 6.75% |

| Leading Region | North America |

| Market Segmentation | By Packaging Type, By End User and By Region |

| Top Key Players | Robert Bosch Packaging Technology GmbH, ISHIDA CO., LTD., PKT s.r.l., WeighPack Systems Inc., Ixapack Global, Imanpack Packaging & Eco Solutions SpA |

Automation and Industry 4.0: There's a strong shift towards integrating automation and Industry 4.0 technologies in vertical form-fill-seal (VFFS) machines, enhancing operational efficiency and real-time monitoring capabilities.

Eco-Friendly Packaging: Manufacturers are increasingly adopting sustainable packaging solutions, including biodegradable and recyclable materials, in response to environmental concerns and consumer demand.

Versatile Packaging Solutions: The industry is focusing on providing flexible and customizable packaging options to cater to diverse product requirements across various sectors.

Enhanced Sanitation: There is an increased emphasis on health and hygiene standards in packaging, especially in the food and pharmaceutical industries, driving the demand for advanced VFFS machines.

Smart Manufacturing: The integration of digitalization and remote monitoring features in VFFS machines is facilitating smart manufacturing practices, allowing for predictive maintenance and improved productivity.

The AI integration improves the vertical form-fill seal (VFFS) machines industry by reducing the downtime of the manufacturing process and giving real time insights. AI-powered sensors monitor machine components in real time. Predicts equipment failures before they occur, preventing unexpected breakdowns. The vertical form-fill-seal (VFFS) machines reduces downtime and maintenance costs by scheduling repairs proactively.

AI-driven computer vision systems can inspect seal integrity, packaging accuracy, and product weight. The artificial intelligence integration identifies defects and inconsistencies in packaging instantly. The artificial intelligence integration reduces waste by ensuring only high-quality products are packaged. AI algorithms analyze machine speed, temperature, and material flow to adjust settings automatically. The artificial intelligence integration ensures consistent sealing, filling accuracy, and material efficiency. The artificial intelligence helps in customization of shape, size and material usage based on product requirements. Enables automated recipe changes for different products, improving machine flexibility.

Lintyco's vertical form-fill-seal (VFFS) machines leverage AI-driven intelligence to optimize performance, reduce errors, and adapt to changing production demands. These machines are designed for energy efficiency and durability, aligning with global eco-conscious trends. Harpak-ULMA offers smart, connected packaging platforms that reduce the complexity, time, and cost of building or extending automated packaging solutions. Their VFFS machines integrate AI and IoT technologies to enhance operational efficiency and adaptability.

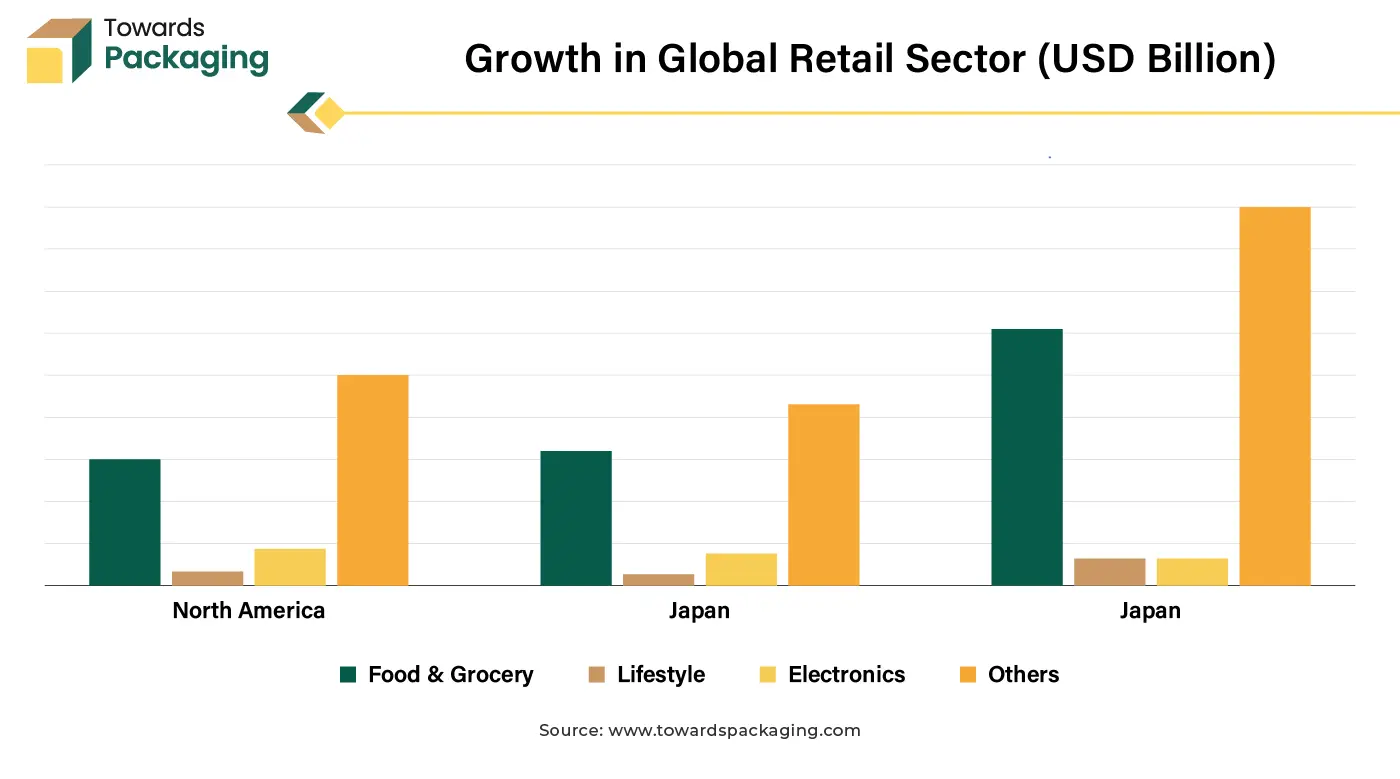

Expansion of online food & grocery delivery services increases demand for flexible packaging. Need for secure, lightweight, and tamper-proof packaging in e-commerce logistics. Retailers and e-commerce businesses require lightweight, durable, and tamper-proof packaging to protect products during transit. Vertical form-fill-seal machines provide customizable pouch designs that improve product safety and shelf appeal. Supermarkets, hypermarkets, and online grocery stores are expanding their ready-to-eat, frozen, and snack food offerings.

E-commerce businesses need cost-efficient, high-speed packaging to handle large order volumes. Retail chains are increasing in-house brands, requiring customized packaging solutions. Vertical form-fill-seal machines allow retailers to package diverse product lines efficiently with private-label branding. Brands are adopting NFC tags, QR codes, and smart packaging for tracking & consumer engagement.

The key players operating in the market are facing issue due to complex maintenance & operational challenges which has estimated to restrict the growth of the vertical form-fill-seal (VFFS) machines market in the near future. Vertical form-fill-seal machines require regular maintenance to ensure smooth operation. Technical expertise is needed for troubleshooting, increasing training costs and dependency on skilled labor. Rising costs of packaging films (plastics, paper, biopolymers) impact machine profitability. Supply chain disruptions affect the availability of packaging materials. Many businesses in emerging economies still rely on manual or semi-automatic packaging due to cost constraints. Lack of awareness and infrastructure slows automation adoption in smaller industries.

Increasing preference for lightweight, space-saving, and cost-effective flexible packaging in food, pharmaceuticals, beverages, and personal care products. Rising e-commerce sales require durable and protective packaging solutions. The increased demand for the flexible packaging has estimated to create lucrative opportunity for the growth of the vertical form-fill-seal (VFFS) machines market in the near future.

Rapid urbanization and changing consumer lifestyles in Latin America, Asia-Pacific, and Africa are boosting demand for packaged foods and household products. Local businesses are investing in automated packaging solutions to improve efficiency.

The bags & pouches segment held a dominant presence in the vertical form-fill-seal (VFFS) machines market in 2024. Vertical form-fill-seal machines can produce hundreds of pouches per minute, making them ideal for high-volume packaging. Vertical orientation allows for efficient floor space utilization in manufacturing plants. The manufacturing of bags and pouches use less material than rigid packaging, reducing production and transportation costs. The bags and pouches packaging suitable for pharmaceuticals, beverages, food, personal care, pet food, and household products. Pouches have flexible design which allows for easy stacking and storage, taking up less space than rigid containers.

The food & beverages segment registered its dominance over the global vertical form-fill-seal (VFFS) machines market in 2024. The food & beverages company use VFFS machines for packaging grains, snacks, cereals, frozen foods, bakery products, and powdered products. The usage of the vertical form-fill-seal machines ensures product freshness, extends shelf life, and provides portion control. The matrix packaging machinery offers a range of vertical form-fill-seal machines equipment known for durability and efficiency to pack coffee, food and produce sectors. Formerly Bosch Packaging Technology, Syntegon provides advanced vertical form-fill-seal (VFFS) machines known for speed, flexibility, and hygiene for confectionery, food and pharmaceutical packaging.

Asia Pacific region dominated the global vertical form-fill-seal (VFFS) machines market in 2024. Growing pharmaceutical production in India, China, and South Korea boosts demand for tamper-proof and hygienic packaging. Asia-Pacific is a global manufacturing hub with lower labor costs and easy access to raw materials. Countries like China and India offer cost-effective machine production and exports.

The China vertical form-fill-seal (VFFS) machines market shows significant growth as the online purchase increases the demand for sustainable packaging in the region. Furthermore, the industries in China are making strategic moves to growth the packaging industry. For instance, in September 2024, Duravant LLC, a worldwide provider of engineering equipment and automation solutions to the food processing, packaging, and material handling industries, announces Denver Lu's appointment to the role of Managing Director, Duravant China Co Ltd. The news comes after the business recently invested in opening a local sales and service branch in Suzhou, China.

With these investments, Duravant is increasing its dedication to growing its local sales and service infrastructure in order to better meet their customers' growing automation needs. Duravant has a long history of assisting international clients operating in China. Due to strong economic growth and rising wages, China is set to overtake all other consumer markets in the world, according to Petros Diamantides, Chief Qperating Officer, Emerging Markets at Duravant.

Traditional industries like food, agriculture, and logistics are changing dramatically as the nation's manufacturing emphasis moves from quantity to quality and from speed to efficiency. The Duravant LLC company observes enormous potential in the Chinese market to expand alliances with both local Chinese strong brands and international clients.

North America region is anticipated to grow at the fastest rate in the vertical form-fill-seal (VFFS) machines market during the forecast period. Rising demand for convenience snacks, foods, frozen meals, and ready-to-eat products in North America boosts the need for efficient packaging solutions. Growing consumption of single-serve and portion-controlled packaging favours the adoption of Vertical form-fill-seal (VFFS) machines. The surge in online grocery shopping and direct-to-consumer brands creates demand in North America for secure and flexible packaging. North America is shifting towards biodegradable, recyclable, and compostable materials.

The U.S. vertical form-fill-seal (VFFS) machines market is estimated to grow at considerable rate due to growing demand for sustainable packaging and food and beverages industry. U.S. market expansion is also supported by the region's emphasis on automation and cost effectiveness. In the competitive landscape of the United States, developments in sustainable packaging materials are also gaining popularity and meeting customer needs for eco-friendly solutions.

Europe region is seen to grow at a notable rate in the foreseeable future. Notable growth in the European region is ascribed to strict laws governing the quality and safety of products. Additionally, this market is heavily influenced by the pharmaceutical industry's need for safe, hygienic packaging. Additionally, consumers' preferences for eco-friendly items are in line with the growing trend towards sustainable packaging solutions. Furthermore, technological advancements that increase productivity and decrease waste are also fueling the expansion of form-fill-seal machines in Europe.

The strong industrial base of Germany, especially in the food and pharmaceutical industries, fuels the need for premium packaging solutions. Additionally, the adoption of eco-friendly packaging technology is encouraged by Germany's dedication to sustainability. Additionally, the emphasis on efficiency and automation in production processes makes form-fill-seal machines even more appealing to producers.

By Packaging Type

By End User

By Region

May 2025

February 2025

February 2025

February 2025