March 2025

.webp)

Principal Consultant

Reviewed By

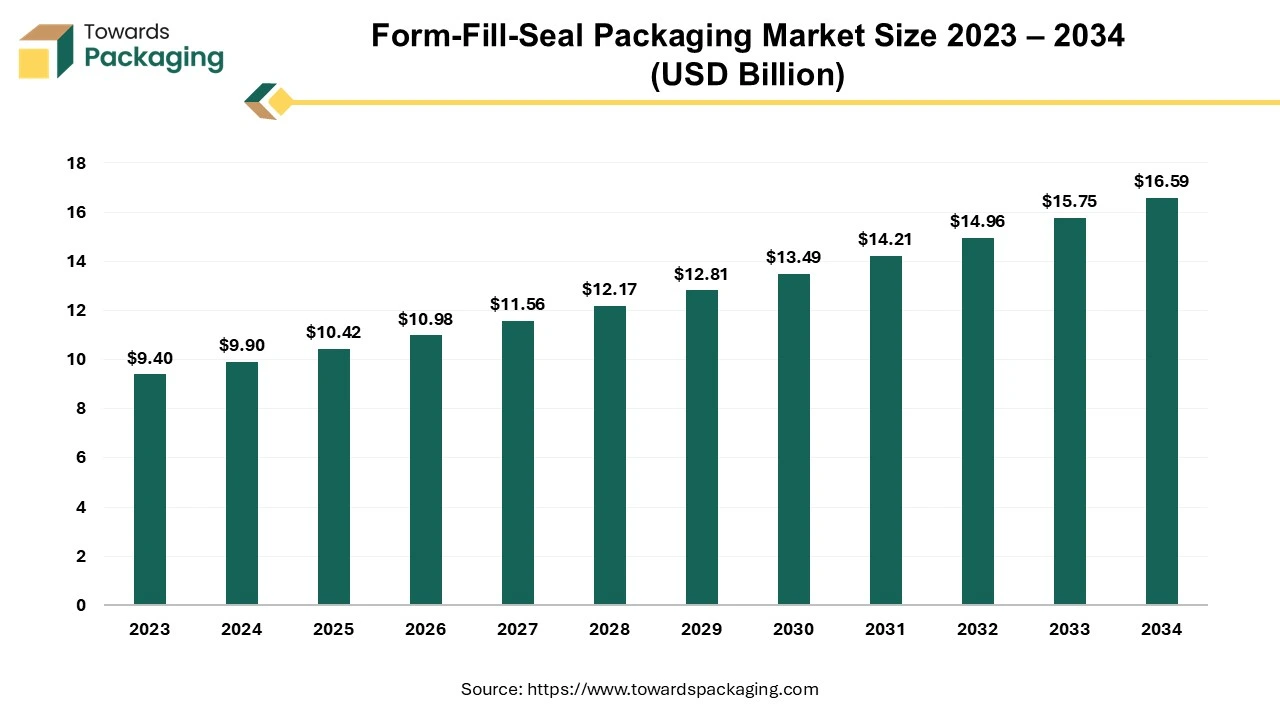

The form-fill-seal packaging market size is forecast to grow at a CAGR of 5.3%, from USD 10.42 billion in 2025 to USD 16.59 billion by 2034, over the forecast period from 2025 to 2034.

Form-fill-seal (FFS) packaging is a system in which a single machine performs numerous duties during the packaging process, such as shaping the package, filling it with product, and sealing it. This procedure is often used with flexible materials like paper, metal foil, plastic film, or a mix. While the phrase occasionally refers to machinery that produces plastic bottles from resin, fills them, and seals them, this discussion is primarily concerned with FFS employing flexible materials, with "film" used broadly to represent the continuous material rolled up on these machines. The ability of FFS packaging machines to minimise human interaction throughout the packaging process is a significant advantage. This not only ensures hygiene but also reduces the chance of infection. These machines are versatile and can handle a variety of materials, including PET and polypropylene (PP), making them suitable for a wide range of packaging needs.

The FFS category is a shining example of innovative packaging. It is critical to develop the next generation of FFS machines, exhibiting cutting-edge equipment and technology for various packaging applications. Businesses can achieve their goals and improve packaging efficiency by using the FFS sector, which provides solutions that are not only efficient but also tailored to specific requirements.

The FFS category is critical in determining the packaging industry's future, focusing on innovation and sustainability. Its commitment to upgrading technology and fulfilling changing market demands highlights its crucial role in influencing the direction of the packaging industry.

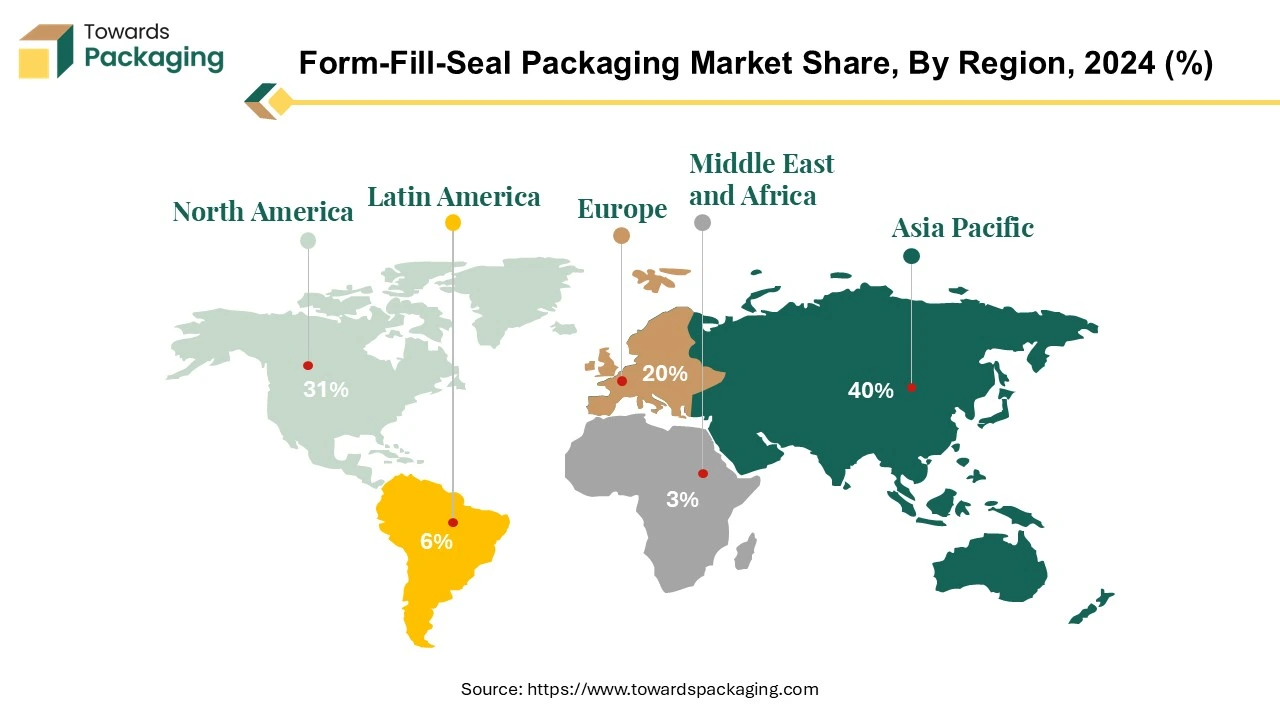

Several important factors have led to the Asia-Pacific region's prominence in the form-fill-seal (FFS) packaging business. The region's strong position results from increased usage in the pharmaceutical industry, growing production levels, and a growing demand for ready-to-eat meals. Production has increased significantly in several sectors in the Asia-Pacific area. The need for effective and automated packaging solutions, including FFS machines, is rising due to the growing production activity. These devices expedite the packing process, increasing total production effectiveness and satisfying the growing needs of many industries.

In the Asia-Pacific area, the demand for ready-to-eat meals has increased due to shifting lifestyles and growing convenience preferences. Such meals are ideally suited for FFS packaging, which provides quick and effective ways to maintain the freshness and calibre of food items. Because FFS machines can handle various materials and packaging requirements, they are perfect for the wide range of ready-to-eat items available on the market.

The Asia-Pacific pharmaceutical industry has seen an increase in the use of FFS packaging. FFS machines are excellent at satisfying the pharmaceutical industry's exacting and hygienic packaging needs. Pharmaceutical product integrity is guaranteed by the automated and regulated nature of FFS packaging, which helps explain the region's dominance in this market sector.

The Asia-Pacific region's dominance in the form-fill-seal packaging market stems from its dynamic industrial landscape, rising demand for convenient food options, and the growing use of FFS technology in pharmaceutical packaging. These elements put the area in a solid position to influence the direction of the FFS Packaging market.

North America is the second-largest form-fill-seal (FFS) packaging market, driven by a convergence of technology breakthroughs, a well-established industrial landscape, and a customer base that values efficiency and innovation. The region's mature manufacturing industry has seen broad adoption of FFS machines in various industries, including food & beverage and pharmaceuticals. This acceptance is supported by North America's commitment to technical advancement, which has positioned FFS technology as a critical component in the packaging processes of many organizations.

FFS technology's progress in North America has been driven by a never-ending quest for innovations, cementing its position as a cornerstone of modern packaging methods. Notably, the region's usage of FFS machines has increased in response to the demand for sustainable and straight forward packaging solutions. These machines excel at achieving operational efficiency and providing customizable packaging solutions that fit consumers changing preferences.

With a consumer base increasingly interested in simplified packaging processes, North America continues to define the FFS packaging market trajectory. The region's influence is distinguished by its capacity to give new solutions to the changing needs of many industries. As industries pivot towards more sustainable and efficient packaging practices, North America's role in promoting the adoption of FFS technology is critical. North America is positioned to play a significant role in determining the direction of the FFS Packaging market due to the region's dedication to innovation and an industry landscape sensitive to changing customer demands.

Vertical Form-Fill-Seal (VFFS) has the most significant share in the packaging section and is widely used around the globe. Vertical Form-Fill-Seal (VFFS) packaging machines are considered standard packaging machinery, providing unique advantages and capabilities and advancing packaging procedures beyond traditional machinery. VFFS machines are widely used in many economic sectors and have become well-liked due to their efficacy, affordability, and capacity to maximise manufacturing floor space. VFFS machines are unique in the packaging solutions market since they are continuous systems intended to shape, fill, and seal packaging. These machines stand out because the entire operation is carried out vertically. This implies that a smooth and effective workflow is produced when one unit is sealed, which causes the next to form. This vertical packaging strategy maximises time and materials because the equipment produces filled and sealed units vertically with little waste.

The extensive use of VFFS machines in various industries is evidence of their adaptability and efficiency in satisfying the needs of contemporary packaging specifications. Their capacity to optimise procedures and minimise wastage positions them as the go-to option for companies looking to boost productivity and make frugal use of their valuable manufacturing space. Fundamentally, vertical form-fill-seal machines are now essential to contemporary packaging strategies, providing a dependable and optimal answer for companies looking for effective and space-conscious packaging solutions in various economic sectors.

Vertical Form Fill Seal (VFFS) machines are adaptable devices that fit into production lines smoothly. They are made especially for packaging across various sectors but are most commonly used in the food packaging industry. These incredibly productive devices are essential to simplifying the packaging process for multiple goods.

VFFS machines are excellent in encasing both liquids and solids. They work based on producing plastic bags from a continuous flat roll of film. These machines' modular design allows flexibility in meeting various packaging specifications, leading to extensive usage in the rapidly changing food packaging sector. Machines that use horizontal form fill seals (HFFS) are frequently used to package non-flowing, solid objects. With its twin sealing and moulding stations, these HFFS machines offer a clear advantage to operations that need to alter pack sizes frequently. Two stations reduce downtime and increase operational efficiency by facilitating quick and easy changeovers.

The intentional implementation of VFFS and HFFS machines into assembly lines demonstrates the industry's dedication to precision and productivity. These machines are a dependable way for companies that deal with a wide range of products-particularly those in the food packaging industry-to satisfy the demands of efficiently packing various items. The capacity of VFFS machines to accommodate both liquid and solid goods, in conjunction with the effective changeover capabilities of HFFS machines, renders them essential elements in the contemporary packaging environment.

The dynamic nature of the food industry has led to a growing need for effective packing automation, with manufacturers seeking to boost production capacity while improving worker safety for those involved in food processing. Due to the increase in demand, cutting-edge technologies are being adopted, most notably the incorporation of industrial robots, which will revolutionise and speed up the packaging process.

Automation of food packaging with industrial robots is a game-changing technology that expedites product sorting and sealing while streamlining the packing process as a whole. In the past, food processing firms needed teams of workers to handle packaging activities because they mainly relied on manual labour to do these jobs. Automation solves the drawbacks of labour-intensive processes and significantly lowers the cost of physical labour while increasing production efficiency.

Using a seal packaging system is a crucial element of this automated process. With this technology, food may be efficiently prepared for shipment thanks to vertical form-fill-seal equipment. The product is inserted into the elongated plastic tube that the vertical form-fill-seal apparatus creates during the process. After that, the machine skilfully closes the package, protecting the contents and handling and sorting the leftover plastic.

Combining automation technology and food packaging improves operational effectiveness and advances the general objective of creating a more secure and efficient food processing environment. The dynamic environment of the modern food sector is becoming increasingly apperent as the industry embraces these innovations, demonstrating the transformative effects of automation on cost-effectiveness, production scalability, and employee productivity.

The competitive landscape of the form-fill-seal packaging market is characterized by established industry leaders such as ProMach, Syntegon Winpak Ltd., SACMI Imola SC, ProAmpac, HDG Verpackungsmaschinen GmbH Huhtamaki Oyj, Mespack and REES MACHINERY GROUP LIMITED. These giants face competition from emerging direct-to-consumer brands, leveraging digital platforms for market entry. Key factors influencing competition include innovation in product offerings, sustainable practices, and the ability to adapt to changing consumer preferences. Additionally, the sector sees dynamic collaborations, acquisitions, and strategic partnerships as companies strive to capture market share in this highly competitive and evolving industry.

By Equipment Type

By End User

By Region

March 2025

March 2025

March 2025

March 2025