April 2025

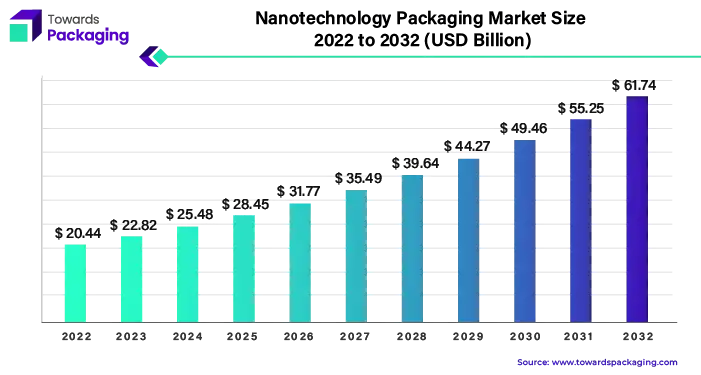

The nanotechnology packaging market is projected to reach USD 77.07 billion by 2034, growing from USD 28.47 billion in 2025, at a CAGR of 11.7% during the forecast period from 2025 to 2034.

Nanotechnology packaging is a future packaging closed to living systems with organic and inorganic nanomaterials taking the role of designer to prepare for the active and intelligent functioning packaging. The term nanotechnology packaging refers to that section of the packaging industry where the nanotechnology, which is the technique from manipulating and utilizing the material at the nanoscale, is applied. A nano packaging is an alternative to prolonged food shelf-life thereby providing more enhanced barrier properties, mechanical strength, antimicrobial properties, and antioxidant properties. It could be a big life saver in the food packaging manufacturing industry which relies heavily on traditional plastics.

The expansion of the nanotechnology packaging market is exerted by the range of its uses in many industries; such is the pace of development. Nanotechnology transforms packaging in terms of special counter-measures for protection of the product, tremendous possibilities for sustainability and also smart functions. One important the use is the uplifting of sealing properties in packaging materials. Nanotechnology has certainly become ubiquitous, the infamous idea that comes with it is that most people know it at a superficial level, if not at all. The data is telling us that more than one third know what it is all about and the fact that they are keeping this information ready to connect it to is even more impressive.

Nano technology makes possible of the research and production of smart packaging solutions partnered with sensors and indicators to read on the go the inside package's environmental conditions.

Nanotechnology innovations have helped nanotechnology-printing methods become a substantial element of the packaging sector. Using nanotechnology for printing, an enterprise can reduce the incidences of counterfeit products and enhance brand recognition and consumer trust through high-quality anti-counterfeit labels and packaging designs. Nanocoating is a novel, cost-effective solution to complement the design of packaging surfaces with scratch resistance and antimicrobial properties. As a result, such packaged products possess durability and good hygiene.

An increase in consumer demand for sustainable and safe packaging solutions, tight environmental regulatory rules, and product development progress can be credited to the prompt growth of the nano market segment. Nanotechnology empowered producers to have different appearance of package, which helped their products to attract consumers with new preferences and meet the standards issued by regulatory agencies. On the verge of changes the packaging sector is even ready for increases and improvements due to the developments and capitalises in the nanotechnologies of that time.

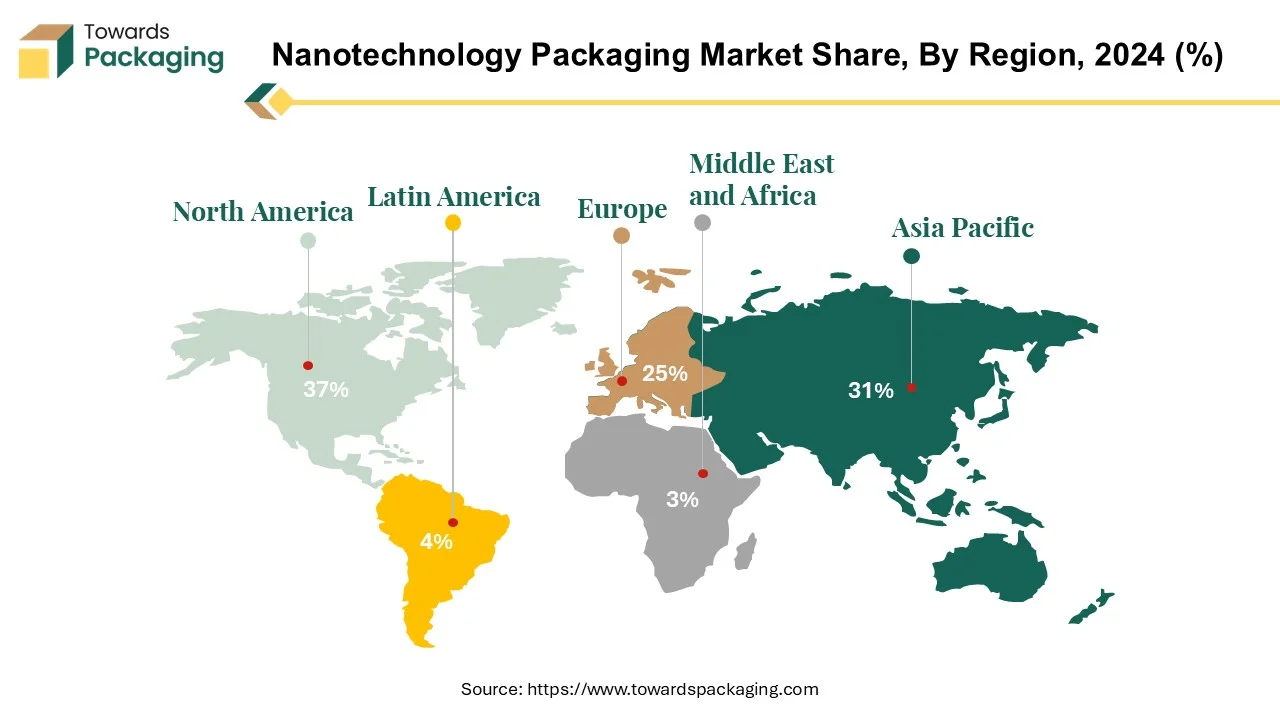

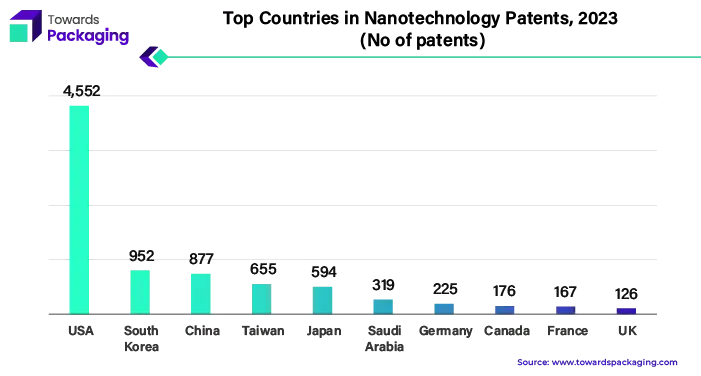

The nano-technology packaging market confronts strong growth, with North America in the foremost position of this movement. With the highest market share, the North American packing market is applying advanced tools and techniques to attain the necessary quality of product packaging. In the case of United States in the driving seat provides almost a third of the worldwide nanotechnology research which accounts for a rather big share.

The US's commitment to nanotechnology can be seen from its huge allocation of budget to research and development (R&D) activities. The administration's plan for the US presidential budget provided $1.7 billion for the National Nanotechnology Initiative, which is an obvious indication that the government approval of nanotechnology projects is strong. Moreover, appreciating the innovative technology that nanotechnology is, the United States has invested significantly, so that total investments have exceeded $31 billion. These investments highlight the nation's role of the proactive player with maximizing nanotechnology benefits through different industries, including packaging.

The North American packaging industry is proceeding with remarkable pace because of such investments and activities. Nanotechnology is widely applied in product packaging that ensure the development of multipurpose solutions with different new functionalities such as improved barrier properties, smart packaging features and sustainability enhancements. Through embracing the nanotechnology, North American companies in packaging sector are not only responding to the consumers' demands for safer and more environmentally friendly packaging, but also keeping abreast of the competition and leading innovation in the global market. Nanotechnology packaging market in North America is driven by flourishing research and development activities, strategic investments and an active stance of the packaging industry towards technology advancement.

Asia-Pacific region (APAC) became the emerging market with a faster growth of the nanotechnology packaging. Major economies such as China, Japan and South Korea are the significant players who produce about 25 percent of the world food waste while urban formal and informal sectors in other regions of South and Southeast Asia contribute 22 percent of the world food waste stock. In view of this formidable task, companies which sell packaging materials as well as end-products in the area are increasingly relying on the application of nanotechnology to reduce food substances wastage by extending food products’ shelf life.

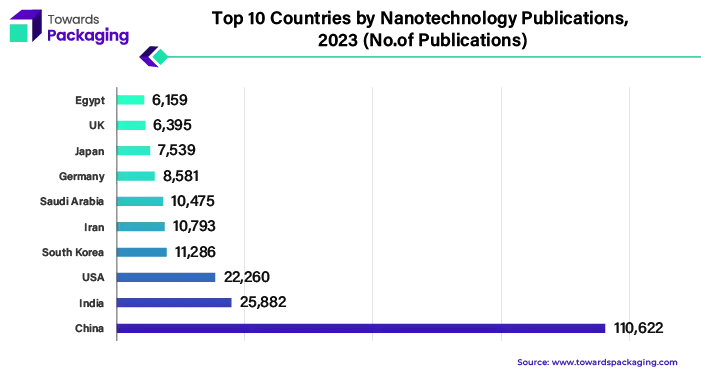

China as the leading nanotechnology implementer is famous for a great 46 percent nano articles’ proportion worldwide. This year again China has reached 100,000 articles threshold for the second time evidencing a relationship between a country's finance, science and industry sectors development. This considerable investment in nanotechnology research can indeed give the manufacturers the power of comprehensive mastery of technology needed to completely take advantage of nanotechnology during the packaging solutions.

The incorporation of nanotechnology into packaging allows manufacturers of APAC region to head on food preservation that will hinder and minimise losses and food waste. Nanotechnology provides avenues to improve materials' properties for wrapping, develop smart packaging solutions that work for real-time monitoring, and integrate active substances towards microbial life and to reduce oxidation. These technological innovations do not only help to raise the shelf-life of food products but as well play a role in the sustainability factors such as food waste decrease in the supply chain. The APAC region's quick embracing of nanotechnology in packaging displays more than just its preference for drug delivery, rejecting an approximately 30% of foodstuffs globally, fighting poverty among the poor who still depend on agri-food products as their major food source and it is due largely to the initiative of the governments of the countries in the APAC region to drive innovation and technological breakthroughs in the packaging.

Nanotechnology-based packaging materials have top barrier properties and can bar more gas, water, and light. These nanocomposite films and coatings give effective protection against oxygen, moisture, UV radiation and other natural factors that contribute to deterioration of quality and decreasing the shelf life of packaged items such as food, medicine, and electronic devices.

Regulatory constraints are a matter of concern for the developers of nanotechnology packaging solutions because of the risks of safety, toxicity, and the environment with nanoscale materials.

Research and development in nanotechnology and materials science continue to bring out innovations and progress in technique and packaging materials.

Active packaging which is a type of smart packaging made in such a way that it extends the lifetime of perishables and improves their overall quality is the second category of smart packaging. The packaging with this special purpose releases and absorbs some compounds which are present within the product and thus it retards processes namely dehydration, growth of microbes, and reaction of oxygen. Even though active packaging has gained attention due to impressive figures since such packaging helped to reduce food and water wastage by 1.1 million tons and 314 billion gallons, respectively, the connected packaging has increased its demand as its user base increased from 54% in 2022 to 81% in 2023.

In the active packaging category, different options are available; each of them is packing specific benefit depending on the needs of a individual consumer. Currently, package swarmed are popular but many substitute for are also at hand. In the synthesis of nanomaterials used in active packaging, two primary techniques are employed: both the bottom-up and top-down methodologies. Nanotechnology is a discrete component of active and intelligent packaging materials' manufacture. These sorts of the nanomaterials are expert at freeing or catching particular component into or out of the content of the package.

Nanotechnology and other high-tech approaches are the foundation of active packaging which serve as the innovative ways of keeping fresh and safe the wrapped products. Through these active control of environment factors within the packaging, this solution provides one to combat problems like foods spoilage and degradation, which leads to satisfaction of the consumer as well as the increase of the product's lifetime.

The nanotechnology packaging market of the food and beverage sector is recording a steady trend due to number of reasons. Increasing demand for environmentally responsible methods of processing, growing rivalries and high health concerns only serve to stimulate innovation within the meat processing sector. Nanotechnology holds the potential for meat products to become more functional and at the same time improve the packaging used around the products. Having already garnered over 400 business all over the globe, including significant players in the food field like Kraft, Nestle, Unilever, and Heinz, nanotechnology has a huge potential. Such figures are being projected to rise in the future given the fact that more companies are recognizing the rewards associated with the application of nanotechnology.

A case is the US, where beer breweries refresh the effervescence in plastic bottles with a particle of nanoscale clay that lasts longer. A scientific breakthrough enables researchers to directly fill microscopic gaps between plastic molecules with nanoparticles, which in result significantly reduce gas escape and thus, prolong the shelf life of beverages.

The transition from laboratory trial to industrial establishment of nanotechnology highlights the effectiveness and implications of this technological discovery in the transformation of food package practices. Nanotechnology will definitely gain the momentum and its prospect in packaging for food and beverage industry is hugely thrilled as more and more business use nanotechnology-enabled solutions.

Bio-sensors have a very important place in the nanotechnology packaging industry providing advanced measurement and control systems for perishable items or goods with quality control. These biosensors are focused on molecules, proteins or compounds detection thus delivering information on the state of the food and its freshness.

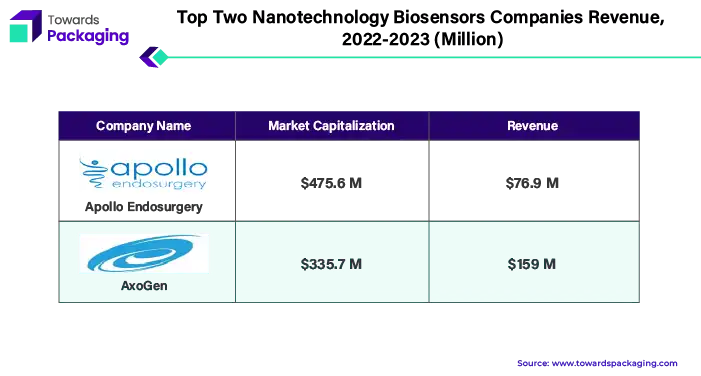

Biosensor business in the nanotechnology packaging technology sector tend to emphasize on it, tech collaboration and market penetration. Such businesses employ research and development, whose product purposes are to improve, biosensor performance with respect to real-time monitoring as well as quality control in packaging applications. In the nanotechnology package biosensors can be bonded with the packaging material or labels, to enable constant monitoring of factors such as temperature, humidity, pH levels and the occurrence of pathogens or the existence of spoilage indicators. This immediate data serves as a basis which producers, distributors, and consumers use to make wise choices concerning the security and quality of the pre-packaged products.

Biosensors provide traceability and transparency along with food production all along the supply chain. By giving immediate information on different environmental factors and product condition sensors improve the inventory management, product quality validation, and regulation standards. Considering the continuous growth of technology, it is possible to project that biosensors will be the lead role shaper of the packaging future in the food, pharmaceutical, and consumer goods sectors.

The competitive landscape of the nanotechnology packaging market is dominated by established industry giants such as Avery Dennison Corporation, BASF, Honeywell International, Mitsubishi Gas Chemical Inc., Clariant Ltd., Emco Packaging Systems, Amcor Limited, 3M Company, Bemis Company, Inc., Chevron Phillips Chemical Company LLC, and Aptar Food. These giants compete with upstart direct-to-consumer firms that use digital platforms to gain market share. Key competitive characteristics include product innovation, sustainable practices, and the ability to respond to changing consumer tastes.

Avery Dennison is innovation-driven and this is carried on in their integration of nanotechnology and packaging. The company dedicates its resources for research and development, which makes possible new smart packaging materials and instruments that constitute multifunctional, sustainable and interactive features. Avery Dennison also works in juxtapose with agent parties to literally address specific market requirements and enlarge its presence in vital regions.

BASF is devoted to explore nanotechnology as a new technique to produce advanced packaging products which perform better and feature sustainability. The entity stresses more so on customer collaboration and co-innovation to suit its products /services to the respective markets’ demands.

Taking advantage of nanotechnology, Honeywell International considers it a prospective mean for more sophisticated packaging, that will be more effective and safer within different industries. The company's strategy is devoted to the creation of novel materials and coatings on material basis with nanoscale features which aid to decrease the diffusivity, increase the durability, and address environmental issues associated with packaging.

Mitsubishi Gas Chemical Inc. makes its research towards the concentration production of nanotechnology as well as collaboration with industry. These are great mechanisms which make the development of nanotechnology possible in product packaging. Company targets the application of nanomaterials in package production with the aim to obtain better resistance properties, longer shelf-life, and better product protection.

By Packaging Type

By End Use

By Product Type

By Region

April 2025

April 2025

April 2025

April 2025