April 2025

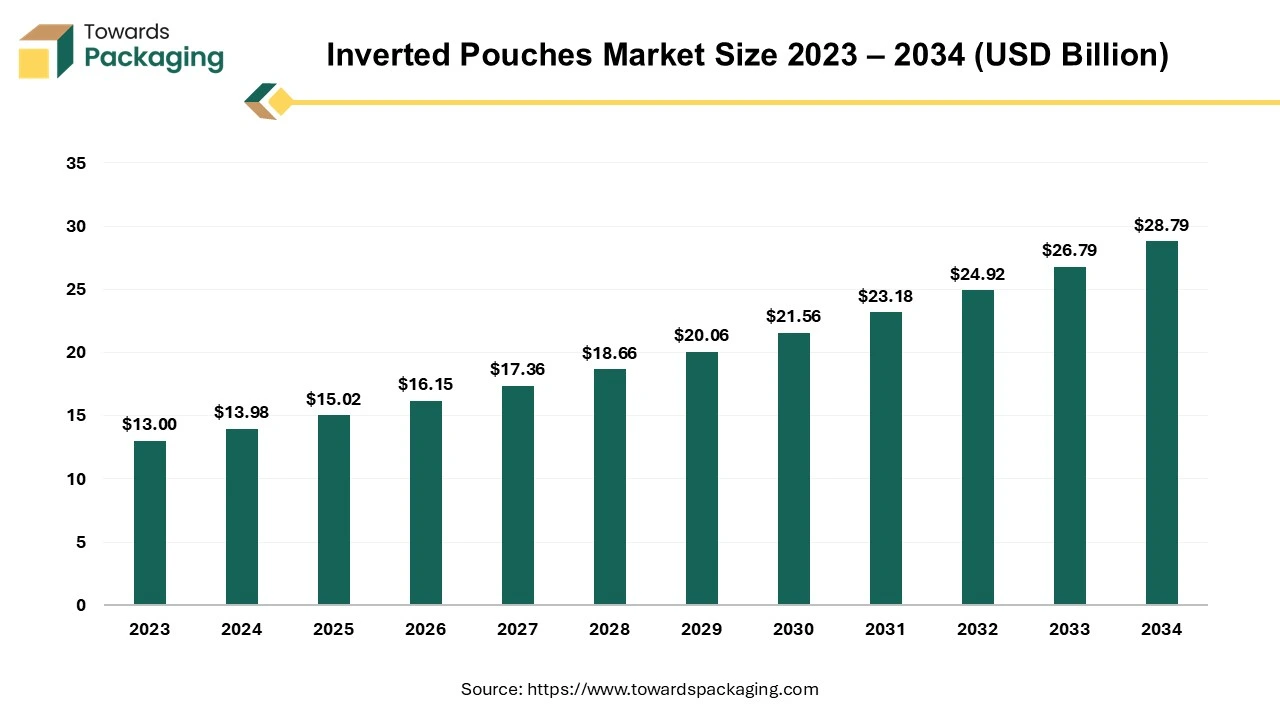

The inverted pouches market is projected to grow from USD 13.98 billion in 2024 to USD 28.79 billion by 2034, expanding at a CAGR of 7.5%. Key market players are focusing on acquisitions and mergers to develop advanced technologies for inverted pouch manufacturing, driving market expansion. Europe dominated in 2024, while Asia Pacific is set to witness the fastest growth.

Unlock Infinite Advantages: Subscribe to Annual Membership

The inverted pouches are known as flexible packaging designs where the pouch is oriented upside down, with the opening or dispensing spout located at the bottom. This design is commonly utilized for products like sauces, condiments, personal care items, or liquid products. The product flows more easily due to gravity, making it easier to dispense the contents without having to shake or squeeze the package repeatedly. These inverted pouches often have a flat base that allows them to stand upright on store shelves, enhancing visibility and stability.

The inverted design helps ensure that the product is used more completely, reducing waste by allowing even the last portions of the product to be easily accessed. Many inverted pouches come with resealable spouts or caps, maintaining product freshness and preventing spills. This packaging style is both consumer-friendly and efficient, enhancing user experience and reducing product waste.

Nowadays, modern consumers favour packaging that provides ease of use. Inverted pouches offer user-friendly designs with features like resealable closures and dispensing caps, improving convenience and preserving product freshness.

Increasing preference for eco-friendly packaging solutions. Inverted pouches, often made from recyclable or biodegradable materials, align with this trend, appealing to environmentally conscious consumers. The industry is shifting towards eco-friendly materials, with some inverted pouches being made from 100% recyclable materials, reducing environmental impact.

Innovations in pouch design and manufacturing technologies have led to the development of high-barrier properties that protect products from external factors, extending shelf life and maintaining quality. Advances in packaging technology have led to the development of inverted pouches that combine the benefits of tubes, pouches, and bottles, offering versatility across various product types

The unique design of inverted pouches provides a large billboard space for branding, improving product visibility and appeal on retail shelves.

AI integration can significantly enhance various aspects of the inverted pouches industry, from production to marketing. The AI integration improve the manufacturing efficiency and helps to predict when machinery needs maintenance, reducing downtime and improving productivity. AI-powered vision systems can detect defects in packaging with high accuracy, ensuring consistent product quality. AI algorithms can optimize manufacturing processes, reducing waste and energy consumption.

AI can help in selecting and designing more sustainable materials, reducing environmental impact while maintaining functionality. AI can optimize packaging processes to minimize material waste during production. AI can analyze consumer behavior to create personalized marketing campaigns, improving customer engagement and sales. AI can be used in e-commerce platforms to recommend products based on consumer preferences and past purchases. AI can optimize delivery routes, reducing transportation costs and improving delivery times. AI can enhance transparency by tracking products from production to delivery, ensuring quality and compliance.

The AI integration helps in analyzing market trends and consumer data to identify opportunities for new product innovations in the inverted pouch segment. AI can monitor competitors’ activities and market positioning, helping companies stay ahead in the market. By integrating AI, the inverted pouches industry can achieve sustainability, greater efficiency, and customer satisfaction, driving growth and innovation.

Inverted pouches are increasingly used for lotions, shampoos, and other personal care items due to their ease of dispensing and reduced waste. The packaging is also gaining traction in the household products sector for items like detergents and cleaners. Increasing launch of the household and personal care products in inverted pouches packaging has estimated to drive the growth of the inverted pouches market in near future.

The key players operating in the market are facing issue due to complex manufacturing process of inverted pouches and competition from alternative packaging, which has estimated to restrict the growth of the inverted pouches market in the near future. The manufacturing process for inverted pouches is more complex compared to traditional packaging, requiring skilled labor and technical expertise. Ensuring consistent quality and sealing integrity can be challenging, leading to potential product defects or recalls.

Traditional rigid packaging solutions, such as bottles and jars, continue to dominate certain market segments due to their familiarity and established production infrastructure.

Other types of flexible pouches without inverted designs may offer similar benefits at potentially lower costs, creating competition within the flexible packaging sector. Limited consumer awareness about the benefits of inverted pouches compared to traditional packaging may slow adoption rates. Both consumers and manufacturers may be resistant to adopting new packaging formats due to the perceived risks and costs associated with change.

Development of high-barrier films and materials that protect product freshness and extend shelf life. Customizable shapes and features cater to various product categories, enhancing versatility and appeal. The large surface area of inverted pouches allows for vibrant graphics and detailed product information, improving shelf visibility and brand differentiation. Some pouches come with interactive or functional features that enhance consumer engagement and experience. Rising demand for the enhanced marketing and brand differentiation, has estimated to create lucrative opportunity for the growth of the inverted pouches market in the near future.

The polyolefin segment held a dominant presence in the inverted pouches market in 2024. Polyolefin materials are highly flexible, allowing for the creation of pouches that are easy to squeeze, handle, and store without compromising the integrity of the packaging. These materials are resistant to tearing, puncturing, and other forms of physical damage, making them ideal for protecting the contents during transportation and use. Polyolefins are generally recognized as safe for food contact applications, meeting regulatory standards for food packaging materials. They do not react with the contents, ensuring that the product's taste and quality remain unchanged.

Polyolefins provide good moisture and gas barrier properties, helping to maintain the freshness and shelf life of the product inside the pouch. They are resistant to many chemicals, which is essential for packaging food, beverages, and personal care products that may contain active ingredients. Polyolefin materials are relatively inexpensive to produce and process, making them a cost-effective choice for large-scale packaging applications.

Advances in recycling technologies are improving the recyclability of multi-layered polyolefin films. The thin, yet strong, nature of polyolefin films allows manufacturers to use less material while still achieving the desired packaging performance, reducing overall material consumption.

The 150-500 ml segment accounted for a significant share of the inverted pouches market in 2024. The inverted design allows for easy dispensing of the product, especially for thicker liquids like sauces, condiments, or personal care products. Consumers can easily squeeze out the contents without much effort, even when the pouch is almost empty. The inverted pouches often have clear windows or are made of transparent material, allowing consumers to see the product inside. This enhances product appeal and helps users gauge how much product is left.

These pouches are compact and take up less space compared to traditional bottles or jars. They are easy to store in kitchens, bathrooms, or other areas, optimizing shelf space. Inverted pouches often have specialized sealing and materials that help extend the shelf life of the product by minimizing air contact and contamination.

Many inverted pouches use less plastic than rigid containers, contributing to reduced packaging waste and a lower environmental footprint. They are generally more economical to produce and transport compared to rigid packaging, which can lower costs for manufacturers and consumers. The lightweight nature of pouches makes them easy to carry and use on the go, catering to busy lifestyles.

The food segment dominated the inverted pouches market globally. The food sector extensively utilizes inverted pouches for sauces, condiments, and beverages, leveraging their convenience and freshness-preserving properties. The growth of health-conscious consumers has driven demand for convenient, portion-controlled packaging in this segment. As lifestyles become busier, consumers seek convenient, easy-to-use packaging for food and beverages. Inverted pouches cater to this demand with features like easy dispensing and resealable spouts, making them ideal for on-the-go consumption. Inverted pouches allow for portion-controlled packaging, which appeals to health-conscious consumers and those seeking convenience in meal preparation.

The food and beverage industry prioritizes packaging that can maintain product freshness and extend shelf life. Inverted pouches with advanced barrier properties protect contents from air, moisture, and light, preserving quality and taste. Inverted pouches are particularly well-suited for liquid and semi-liquid products like sauces, condiments, beverages, and purees. Their user-friendly design makes them a preferred choice for packaging such products. The flexible and customizable nature of inverted pouches makes them an attractive option for new product launches, allowing brands to experiment with unique designs and packaging formats.

Europe held a significant share of the inverted pouches market in 2024. Europe is home to some of the world’s leading packaging technology companies. The region invests heavily in research and development, allowing for the innovation of packaging solutions like inverted pouches that offer convenience, durability, and enhanced shelf life. Consumers in the region increasingly seek products that are easy to use, portable, and convenient. Inverted pouches align with these preferences, particularly in food, beverages, personal care, and cleaning products, driving demand.

European countries have a well-established manufacturing infrastructure that supports large-scale production of flexible packaging solutions, including inverted pouches. This infrastructure allows for cost-effective production and quick distribution of packaging materials.

Asia Pacific region is anticipated to grow at the fastest rate in the inverted pouches market during the forecast period. APAC countries, particularly China and India, have a large and rapidly growing consumer base with increasing disposable incomes. This fuels demand for convenient packaging solutions, including inverted pouches, especially in food, beverages, and personal care products. The region has made significant strides in packaging innovation, with companies in APAC investing in advanced technologies that improve the efficiency, durability, and cost-effectiveness of inverted pouches. This is crucial for meeting the demands of modern consumers who expect convenience and sustainability.

Asia Pacific countries, especially in Southeast Asia, have a competitive advantage in terms of labor and production costs. This makes manufacturing inverted pouches more cost-effective, allowing local producers to meet both domestic and international demand at competitive prices. Asia Pacific region plays dominant role in global trade also plays a part, as many of the region’s packaging manufacturers export inverted pouches to other regions, including North America and Europe. This helps solidify its leadership in the global market.

In order to launch a first-of-its-kind flexible stand-up pouch with over 50% Post-Consumer Recycled (PCR) content suitable for food packaging throughout the package, API Group and its subsidiary Accredo Packaging, a manufacturer of more environmentally friendly packaging solutions in the food and consumer products markets, team up with the Fresh-Lock team at Presto Products, a division of Reynolds Consumer Products.

By Material

By Capacity

By End User

By Region

April 2025

March 2025

March 2025

March 2025