April 2025

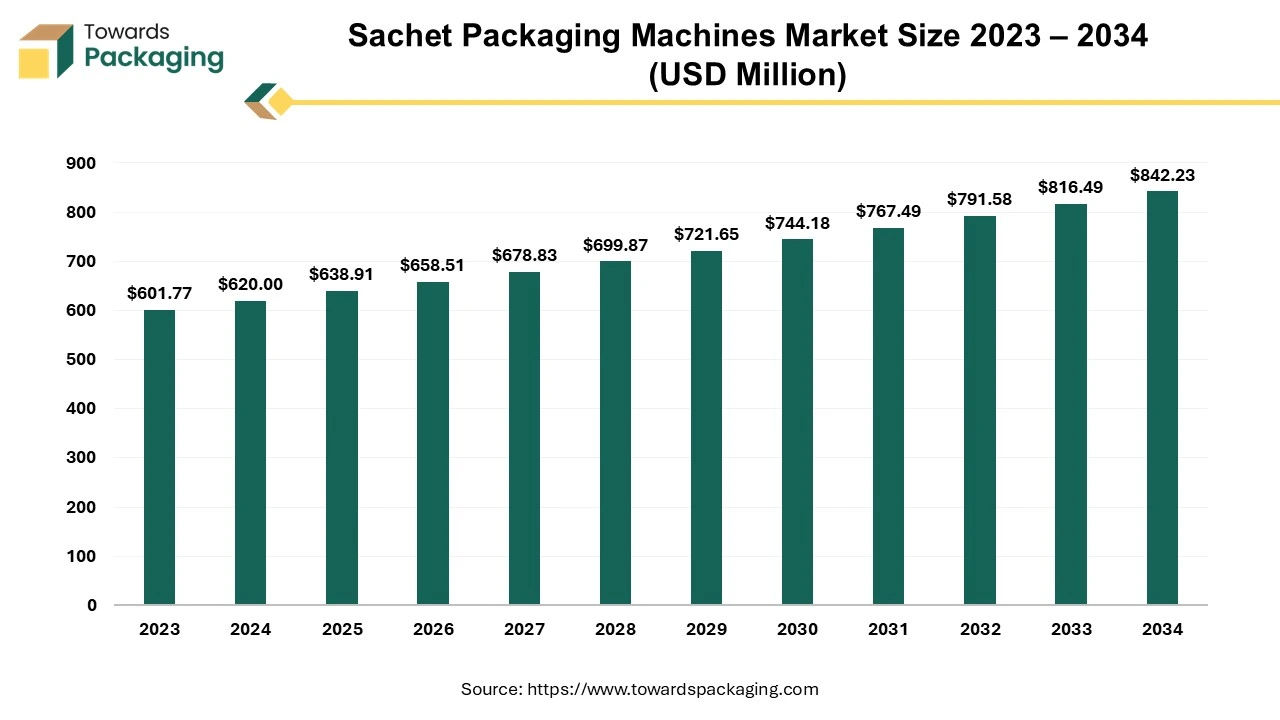

The global sachet packaging machines market size was evaluated at US$ 620.00 billion in 2024 and is expected to attain around US$ 842.23 billion by 2034, growing at a CAGR of 3.05% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

Sachet packaging refers to small, sealed, single-use or multi-use flexible pouches made of plastic, foil, paper, or laminates. It is commonly used for pharmaceuticals, food, personal care, and industrial products. Sachets are cost-effective, lightweight, and convenient, making them ideal for unit-dose packaging of powders, liquids, gels, and granules. A sachet packaging machine is an automated system that forms, fills, and seals sachets in a high-speed, precise, and efficient manner. These machines are widely used in the pharmaceutical, food, cosmetics, and chemical industries.

There's a significant shift towards eco-friendly materials, including biodegradable substances, plant-based polymers, and recycled content. These sustainable options aim to reduce environmental impact and cater to the growing consumer demand for greener packaging.

The integration of Internet of Things (IoT) sensors into packaging allows real-time monitoring of factors like temperature, humidity, and product freshness. This advancement enhances food safety and quality control throughout the supply chain.

The increasing preference for convenient, single-use products are significantly boosting the sachet packaging market. This trend is evident in the rise of travel-sized personal care items and single-use food products.

The integration of Artificial Intelligence (AI) in sachet packaging machines is revolutionizing the industry by improving accuracy, efficiency, and sustainability. AI-powered robotic arms and sensors optimize the form-fill-seal process, reducing human intervention. Machine learning algorithms predict and adjust settings in real time, ensuring consistent packaging quality. AI-driven predictive analytics monitor machine health and detect issues before failures occur, minimizing unplanned downtime. Self-learning systems can recommend maintenance schedules, extending machine lifespan. AI-based computer vision systems inspect sachets for seal integrity, labeling errors, and defects, ensuring high-quality packaging. AI enables QR codes, RFID tags, and blockchain integration, ensuring product authenticity and tracking.

AI-driven machines adapt to different sachet sizes, materials, and designs without manual adjustments. The integration artificial intelligence allows customization and flexibility of sachets. Automatic recipe changes allow rapid switching between products, increasing productivity. AI helps in material reduction and optimization, leading to eco-friendly packaging. Smart algorithms analyze packaging waste and suggest more efficient material usage.

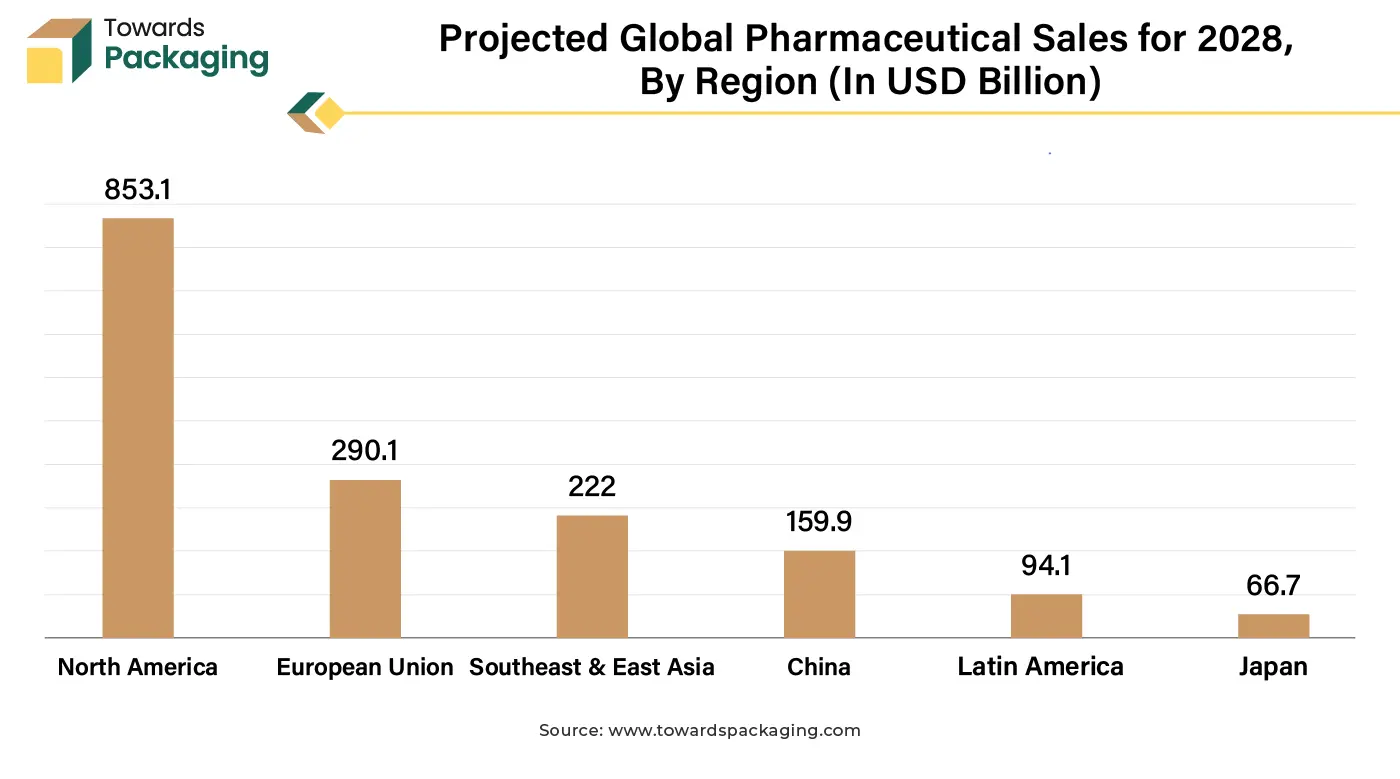

Rising production of unit-dose medications, oral rehydration salts, and powdered supplements fuels demand for sachet packaging machines. Regulatory standards for safe, single-use packaging in pharmaceuticals boost investment in advanced packaging solutions. Hence, the growth of the pharmaceutical & healthcare sector has estimated to drive the growth of the sachet packaging machines market in the near future.

The key players operating in the market are facing challenges due to competition from alternative packaging and strict regulatory compliance, which may restrict the growth of the sachet packaging machines market in the near future. The pharmaceutical and food industries must comply with stringent U.S. Food and Drug Administration, European Union, and International Organization for Standardization regulations, increasing the complexity of manufacturing. Frequent changes in packaging laws demand constant upgrades, adding to operational costs. Flexible pouches, biodegradable wraps, and refillable containers are gaining popularity as alternatives. Brands are shifting toward eco-friendly bulk packaging, reducing demand for sachets.

Automation, IoT integration, and AI-based monitoring improve efficiency, reduce waste, and enable high-speed production. Demand for customizable and multi-functional machines that handle different packaging materials and sizes. Shift toward biodegradable, recyclable, and compostable sachets drives innovation in packaging machines. Regulations restricting single-use plastics push companies to invest in eco-friendly sachet production.

The 201 to 350 sachets per minute segment held a dominant presence in the sachet packaging machines market in 2024. The 201 to 350 sachets per minute (SPM) segment is growing rapidly due to increasing demand for high-speed, efficient, and automated packaging solutions. Industries such as pharmaceuticals, food & beverages, and personal care require high-output packaging to meet growing consumer demand. Manufacturers prefer faster machines to improve productivity and reduce labor costs.

AI and IoT-enabled machines optimize performance, ensuring consistent output at high speeds. Robotic integration allows real-time adjustments, reducing downtime and improving efficiency. Increasing demand for single-use sachets in instant coffee, protein powders, sauces, and personal care products is boosting market growth. High-speed sachet machines meet the need for cost-effective, small-portion packaging. Increasing online sales and demand for ready-to-use and travel-friendly sachets drive the need for high-speed packaging solutions.

The VFFS (Vertical Form-Fill-Seal) segment led the global sachet packaging machines market. VFFS machines operate at high speeds, significantly reducing packaging time. Their automated systems ensure consistent and accurate filling, which is crucial for large-scale manufacturing operations. By automating the packaging process, VFFS machines minimize labor costs and optimize the use of packaging materials, leading to reduced waste and lower material expenses. VFFS machines can produce various bag sizes and styles, including pillow pouches and gusseted bags, catering to diverse packaging requirements. Modern VFFS machines offer features like gas flushing, modified atmosphere packaging, and easy integration with other equipment, further enhancing product preservation and packaging efficiency.

The multiple lane segment accounted for a significant share of the market in 2024. By operating multiple lanes simultaneously, these machines significantly boost output, making them ideal for high-demand applications. Advanced control systems enable precise filling and sealing, reducing product wastage and ensuring consistent quality. Capable of handling liquids, powders, and granules, multi-lane machines cater to diverse packaging needs. These machines can produce various bag styles, such as stick packs and sachets, accommodating different product requirements.

The granules segment registered its dominance over the global sachet packaging market in 2024. Sachets are designed to hold single servings of products, which helps in maintaining the freshness and quality of granules. By sealing the product in airtight pouches, sachets protect the contents from environmental factors such as moisture and air, thereby extending shelf life and ensuring that each serving is as fresh as the first. Sachets are lightweight and easy to carry, making them ideal for consumers who need a convenient, on-the-go option. Their small size allows for easy storage and handling, enhancing the overall user experience.

The flat surface of sachets provides ample space for branding, product information, and promotional content. This feature allows manufacturers to effectively communicate with consumers and enhance brand visibility, potentially influencing purchasing decisions. The slim profile of sachets enables more efficient use of shelf space, both in retail environments and during transportation. Their design allows for higher stacking densities, reducing storage and shipping costs.

The food and beverage segment to dominated the market in 2024. Sachet packaging is widely used in the food and beverage industry due to its convenience, cost-effectiveness, and ability to preserve product freshness. Common applications include single-use portions of condiments (such as ketchup, mustard, and mayonnaise), spices, instant coffee, sugar, and snacks. Sachets are effective for promotional campaigns, allowing consumers to try new products without committing to full-size purchases, thus driving product trials and boosting sales. These advantages make sachet packaging a preferred choice for many food and beverage companies aiming to enhance consumer experience while optimizing packaging efficiency.

Asia Pacific region dominated the global sachet packaging machines market in 2024. Rapidly growing FMCG and pharmaceutical sector in Asia Pacific has estimated to drive the growth of sachet packaging machines market in Asia Pacific region. Rising demand for single-use sachets in food & beverages, personal care, and pharmaceuticals is a major driver. Increased online shopping and modern retail formats in Asia Pacific drive demand for flexible packaging solutions, including sachets for samples and trial-size products. Availability of low-cost labor and raw materials makes production more economical in countries like China, India, and Indonesia.

One of the industries with the fastest growth is India, which produces goods for the food and beverage, pharmaceutical, and personal care sectors. For items to be stored and transported safely, all of these businesses require packaging solutions in a variety of sizes. Because of its affordable prices and capacity to serve a variety of customers in both rural and semi-urban areas, sachet packing has gained popularity in India. The makers can sell products in tiny amounts by using sachet packing machines, which lowers prices and reduces waste production.

The manufacturing sector in the nation contributes 16–17% of the GDP and is expected to grow in the years to come, according to the India Brand Equity Foundation (IBEF). In order to provide the required packaging solution with the highest production capacity, businesses are investing in sachet packaging machines as a result of this increase. As a result, during the evaluation phase, there would be a significant demand for sachet packing equipment.

North America region is anticipated to grow at the fastest rate in the global sachet packaging machines market during the forecast period. Expansion of instant coffee, energy drinks, sauces, and functional foods in sachets due to changing consumer preferences., has estimated to drive the growth of sachet packaging machines market in North America region. North America has a well-developed packaging industry with companies investing in advanced technologies. Presence of major players like Mespack, Viking Masek, and Matrix Packaging Machinery boosting market growth.

The U.S. sachet packaging machines market is estimated to grow at rapid rate due to expansion of food and beverage industry in the U.S. region. Growth of meal kits and online grocery deliveries in U.S. region boosts small, portioned packaging. Consumers prefer portable, small, and single-use packaging for products like condiments, pharmaceuticals, personal care items, and nutraceuticals. To meet the rising demand of sachets in the U.S. the key players operating in the U.S. are increasing taking efforts for launching sustainable sachet packaging.

By Capacity

By Product Type

By Machine Lane

By Application

By End Use

By Region

April 2025

April 2025

April 2025

April 2025